Lek-Heng Lim uses tools from algebra, geometry and topology to answer questions in machine learning.

How far away are we from AGI? Does OpenAI have the right approach? Leave a comment below with what you think!

00:00 Intro.

00:42 What is AGI?

01:08 OpenAI’s Origin Story.

02:25 Enter GPT and Dall-E

03:15 OpenAI’s Roadmap.

04:33 Closing Thoughts.

Please like this video and subscribe to my channel if you want to see more videos like this!

Follow me on other platforms so you’ll never miss out on my updates!

💌 Sign up for my newsletter! https://alexchao.substack.com/subscribe.

🐦 Follow me on Twitter https://twitter.com/alexchaomander.

👥 Connect with me on LinkedIn https://www.linkedin.com/in/alexchao56/

Sources:

Summary: According to researchers, language model AIs like ChatGPT reflect the intelligence and diversity of the user. Such language models adopt the persona of the user and mirror that persona back.

Source: Salk Institute.

The artificial intelligence (AI) language model ChatGPT has captured the world’s attention in recent months. This trained computer chatbot can generate text, answer questions, provide translations, and learn based on the user’s feedback. Large language models like ChatGPT may have many applications in science and business, but how much do these tools understand what we say to them and how do they decide what to say back?

The FDA denied Elon Musk’s application to test his brain chip on humans. In addition to ruining Twitter, Elon Musk is on a mission to plant AI technology into the human brain. Neuralink is one of Musk’s five companies, and it’s in the process of developing neural-interface technology, a tech advancement that would mean putting chips in human brains.

Low-cost robots that perfectly mimic parts of the human body foreshadow a future in which humanoid robots do all the work people don’t want.

Artificial Intelligence AI

🖤 Become an AI & Robots fan & get access to perks: https://www.youtube.com/channel/UCi-vwe-lm_tgxEdlxf690Aw.

Did you think that technology getting too advanced and wiping away humanity was something that happened only in movies? You might be shocked by what you find today.

Robots ‘will reach human intelligence by 2029 and life as we know it will end in 2045’.

This isn’t the prediction of a conspiracy theorist, a blind dead woman or an octopus but of Google’s chief of engineering, Ray Kurzweil.

Kurzweil has said that the work happening now ‘will change the nature of humanity itself’.

Note: ChatGPT is coming to openai API soon, you can sign up in their waiting list. Here is a link for openAI’s ChatGPT API waitlist: https://share.hsforms.com/1u4goaXwDRKC9-x9IvKno0A4sk30

You might have already heard about ChatGPT, in case you haven’t, ChatGPT is a chatbot language model developed by OpenAI. It is a variant of the GPT-3 language model, specifically designed for conversational language generation.

The following definition is generate by ChatGPT (you can try it out at https://chat.openai.com/chat):

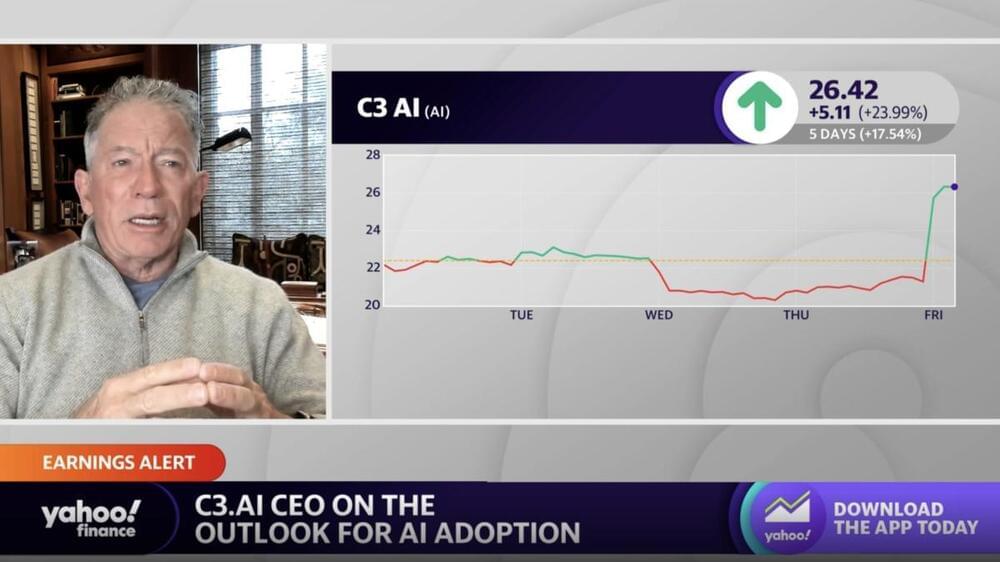

C3.ai Founder & CEO Tom Siebel joins Yahoo Finance Live to discuss company earnings, the buzz around ChatGPT, the ongoing AI hype cycle, and the outlook for the computer software company as tech grapples with AI adoption.

Video Transcript

JULIE HYMAN: C3.AI has been riding the huge buzz around artificial intelligence this year. The shares have gone up a lot and they’re still going up spurred by ChatGPT and the buzz around that. But the company does have a longer history.