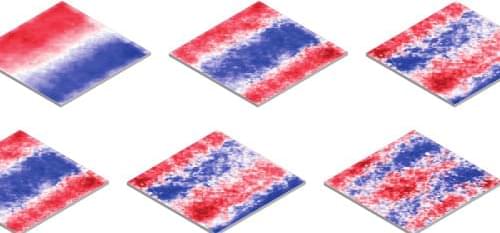

The observation of the onset of turbulence in a gas of bosons allows researchers to explore how turbulence comes to life.

Despite over a century of trying, physicists have yet to develop a complete theory of turbulence—the complex, chaotic motion of a fluid. Now Maciej Gałka of the University of Cambridge and colleagues have taken a step in that direction by witnessing the onset of turbulence in a quantum gas and observing its evolution over roughly 100 ms [1]. The finding could help scientists answer open questions in turbulence, which is observed in systems ranging from ocean waves to star interiors.