A magnetic nanoparticle (MNP)-based platform is introduced for the spatially controlled viral transduction in retina explants and whole eyes. The platform uses magnetic fields to guide adeno-associat…

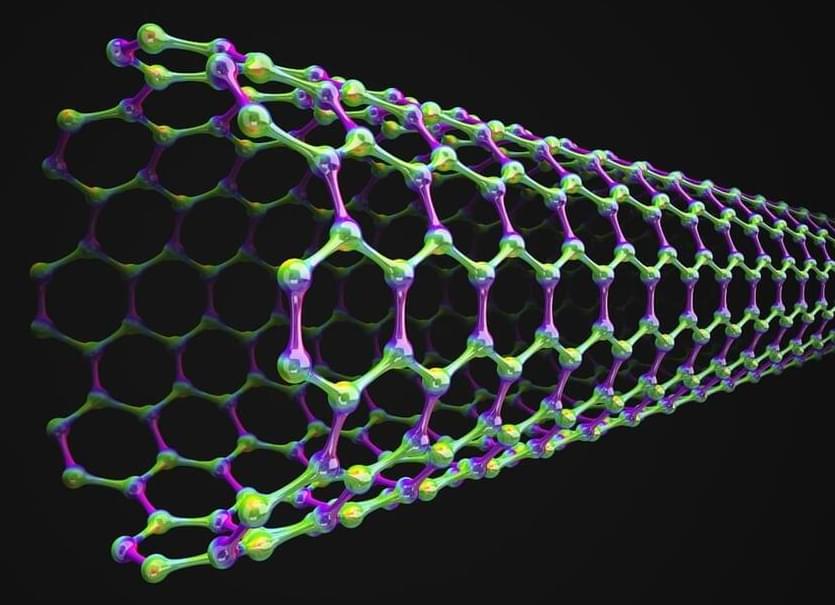

Arizona-based startup Mechnano has exited “stealth mode” in the research and development of its carbon nanotube (CNT) technology for 3D printing materials.

The company has developed its first product, an electrostatic discharge (ESD) resin that delivers dissipative properties to 3D printed parts without compromising mechanical properties.

“These are extraordinary breakthroughs for additive manufacturing materials,” said Steven Lowder, Mechnano’s Founder and CEO. “By focusing on the nanoscale, or the molecular level, we are able to make exponential improvements in AM materials at the macro-level.

A new technology to continuously place individual atoms exactly where they are needed could lead to new materials for devices that address critical needs for the field of quantum computing and communication that cannot be produced by conventional means, say scientists who developed it.

A research team at the Department of Energy’s Oak Ridge National Laboratory created a novel advanced microscopy tool to “write” with atoms, placing those atoms exactly where they are needed to give a material new properties.

“By working at the atomic scale, we also work at the scale where quantum properties naturally emerge and persist,” said Stephen Jesse, a materials scientist who leads this research and heads the Nanomaterials Characterizations section at ORNL’s Center for Nanophase Materials Sciences, or CNMS. “We aim to use this improved access to quantum behavior as a foundation for future devices that rely on uniquely quantum phenomena, like entanglement, for improving computers, creating more secure communications and enhancing the sensitivity of detectors.”

While current treatments for ailments related to aging and diseases like type 2 diabetes, Alzheimer’s, and Parkinson’s focus on managing symptoms, Texas A&M researchers have taken a new approach to fight the battle at the source: recharging mitochondrial power through nanotechnology.

Led by Dr…

When we need to recharge, we might take a vacation or relax at the spa. But what if we could recharge at the cellular level, fighting against aging and disease with the microscopic building blocks that make up the human body?

When we need to recharge, we might take a vacation or relax at the spa. But what if we could recharge at the cellular level, fighting against aging and disease with the microscopic building blocks that make up the human body?

The ability to recharge cells diminishes as humans age or face diseases. Mitochondria, often called the powerhouse of the cell, are central to energy production. When mitochondrial function declines, it leads to fatigue, tissue degeneration, and accelerated aging. Activities that once required minimal recovery now take far longer, highlighting the role that these organelles play in maintaining vitality and overall health.

While current treatments for ailments related to aging and diseases like type 2 diabetes, Alzheimer’s, and Parkinson’s focus on managing symptoms, Texas A&M researchers have taken a new approach to fight the battle at the source: recharging mitochondrial power through nanotechnology.

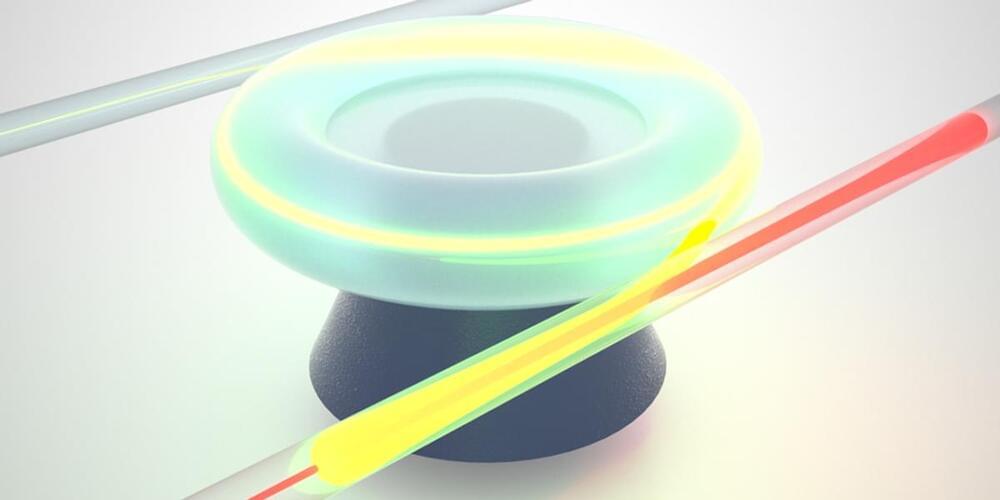

Researchers have created a disk-like nanostructure that dramatically improves light frequency conversion efficiency. This innovation in photonics combines material and optical resonances in a compact form, paving the way for advanced optical and photonic applications.

Scientists at Chalmers University of Technology, in Sweden, have for the first time succeeded in combining two major research fields in photonics by creating a nanoobject with unique optical qualities. Since the object is a thousand times thinner than a human hair, yet very powerful, the breakthrough has great potential in the development of efficient and compact nonlinear optical devices. “My feeling is that this discovery has a great potential,” says Professor Timur Shegai, who led the study at Chalmers.

Harnessing Light With Advanced Photonics.

Ribonucleic acid (RNA) is a vital biological molecule that plays a significant role in the genetics of organisms and is essential to the origin and evolution of life. Structurally similar to DNA, RNA carries out various biological functions, largely determined by its spatial conformation, i.e. the way the molecule folds in on itself.

Now, a paper published in the journal Proceedings of the National Academy of Sciences (PNAS) describes for the first time how the process of RNA folding at low temperatures may open up a novel perspective on primordial biochemistry and the evolution of life on the planet.

The study is led by Professor Fèlix Ritort, from the Faculty of Physics and the Institute of Nanoscience and Nanotechnology (IN2UB) of the University of Barcelona, and is also signed by UB experts Paolo Rissone, Aurélien Severino, and Isabel Pastor.

In recent years, a community of researchers from various universities and institutes across Europe and the United States set out to explore the physics of micro-and nano-mechanical devices coupled to light. The initial focus of these investigations was on demonstrating and exploiting uniquely quantum effects in the interaction of light and mechanical motion, such as quantum superposition, where a mechanical oscillator occupies two places simultaneously. The scope of this work quickly broadened as it became clear that these so-called optomechanical devices would open the door to a broad range of new applications.

Hybrid Optomechanical Technologies (HOT) is a research and innovation action funded by the European Commission’s FET Proactive program that supports future and emerging technologies at an early stage. HOT is laying the foundation for a new generation of devices that bring together several nanoscale platforms in a single hybrid system. It unites researchers from thirteen leading academic groups and four major industrial companies across Europe working to bring technologies to market that exploit the combination of light and motion.

One key set of advances made in the HOT consortium involves a family of non-reciprocal optomechanical devices, including optomechanical circulators. Imagine a device that acts like a roundabout for light or microwaves, where a signal input from one port emerges from a second port, and a signal input from that second port emerges from a third one, and so on. Such a device is critical to signal processing chains in radiofrequency or optical systems, as it allows efficient distribution of information among sources and receivers and protection of fragile light sources from unwanted back-reflections. It has however proven very tricky to implement a circulator at small scales without involving strong magnetic fields to facilitate the required unidirectional flow of signals.