Two types of nanotechnology, metalenses and metamaterials, could soon make Harry Potter’s invisibility cloak a reality.

The Research Brief is a short take about interesting academic work.

A new type of material can learn and improve its ability to deal with unexpected forces thanks to a unique lattice structure with connections of variable stiffness, as described in a new paper by my colleagues and me.

The new material is a type of architected material, which gets its properties mainly from the geometry and specific traits of its design rather than what it is made out of. Take hook-and-loop fabric closures like Velcro, for example. It doesn’t matter whether it is made from cotton, plastic or any other substance. As long as one side is a fabric with stiff hooks and the other side has fluffy loops, the material will have the sticky properties of Velcro.

A newly discovered structure located deep in the heart of a thick cloud of gas and dust more than 450 light-years away is the signature of a pair of baby stars in the throes of formation.

A team of astronomers have identified a previously unseen bubble at the center of a stellar nursery called Barnard 18 in the Taurus molecular cloud complex, likely carved from the surrounding gas as two emerging stars therein formed and grew.

It’s only the second time astronomers have identified such a bubble with the ejection of material or ‘outflow’ associated with a growing star. The newly discovered structure could help scientists learn more about how stars affect their environment as they grow.

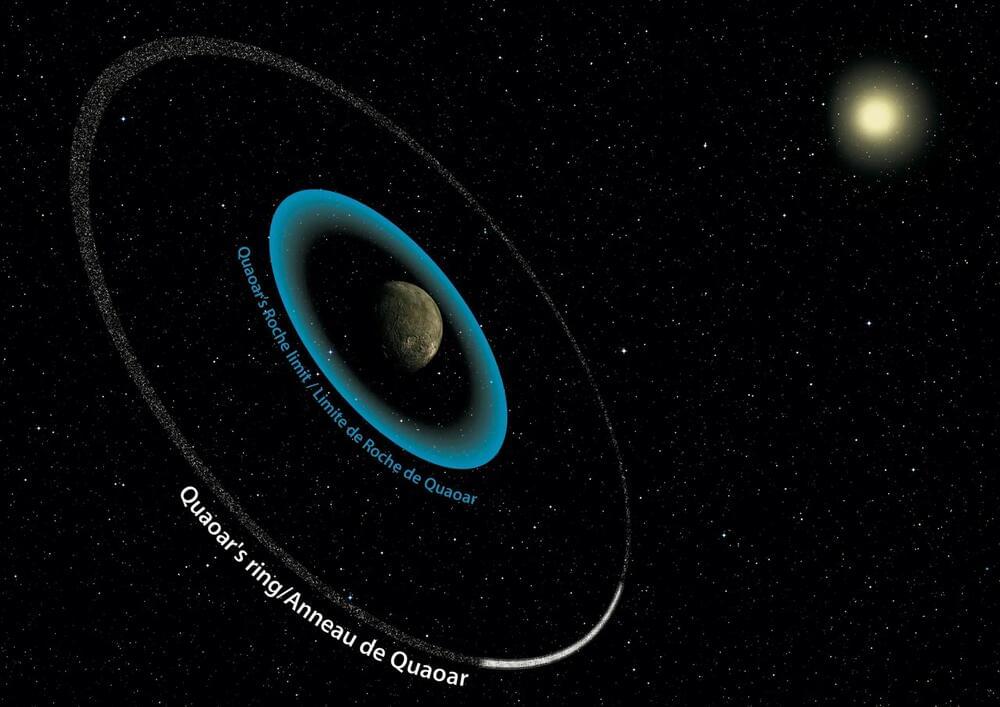

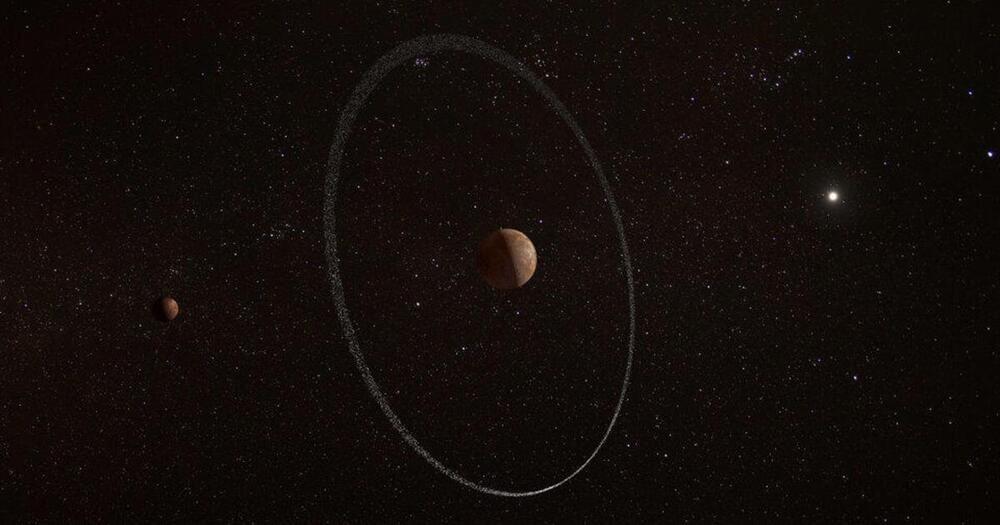

During a break from looking at planets around other stars, the European Space Agency’s CHaracterising ExOPlanet Satellite (Cheops) mission has observed a dwarf planet in our own Solar System and made a decisive contribution to the discovery of a dense ring of material around it.

The dwarf planet is known as Quaoar. The presence of a ring at a distance of almost seven and a half times the radius of Quaoar, opens up a mystery for astronomers to solve: why has this material not coalesced into a small moon?

One of the most interesting stars in the Milky Way is still serving up more than its fair share of intrigue.

In October 2020, SGR 1935+2154, the magnetar responsible for spitting out radio signals never before detected in our home galaxy, unexpectedly slowed down.

Now, scientists believe the rotational slowdown could be evidence of a volcano-like eruption on its surface, spewing material out into space that altered the star’s environment enough to decelerate the spinning of the planet minutely.

“When we put everything together, we saw drops in brightness that were not caused by Quaoar, but that pointed to the presence of material in a circular orbit around it,” said Bruno Morgado of the Universidade Federal do Rio de Janeiro in a statement. “The moment we saw that we said, ‘Okay, we are seeing a ring around Quaoar.’”

Quaoar is part of a collection of about 3,000 dwarf planets known as trans-Neptunian objects, which are beyond the orbit of the planet Neptune.

Scientists are now wondering why the dense material in Quaoar’s ring has not come together to form a small moon, because the ring itself is “at a distance of almost seven and a half times the radius of Quaoar,” the ESA said.

On September 24, 2023, the sample return capsule will detach from the spacecraft, perform an entry, descent and landing sequence, and touch down in the Utah desert.

Thanks to our contribution to the mission, Canada will receive a portion of the asteroid material!

The power to turn invisible, which has long been a hallmark of science fiction and fantasy, would be a revolutionary technical breakthrough. Check out how scientists are making an invisibility cloak into reality.

Despite decades of innovation in fabrics with high-tech thermal properties that keep marathon runners cool or alpine hikers warm, there has never been a material that changes its insulating properties in response to the environment. Until now.

University of Maryland researchers have created a fabric that can automatically regulate the amount of heat that passes through it. When conditions are warm and moist, such as those near a sweating body, the fabric allows infrared radiation (heat) to pass through. When conditions become cooler and drier, the fabric reduces the heat that escapes. The development was reported in the February 8, 2019 issue of the journal Science.

The researchers created the fabric from specially engineered yarn coated with a conductive metal. Under hot, humid conditions, the strands of yarn compact and activate the coating, which changes the way the fabric interacts with infrared radiation. They refer to the action as “gating” of infrared radiation, which acts as a tunable blind to transmit or block heat.