The chip is an artificial neuron, but nothing like previous chips built to mimic the brain’s electrical signals. Rather, it adopts and adapts the brain’s other communication channel: chemicals.

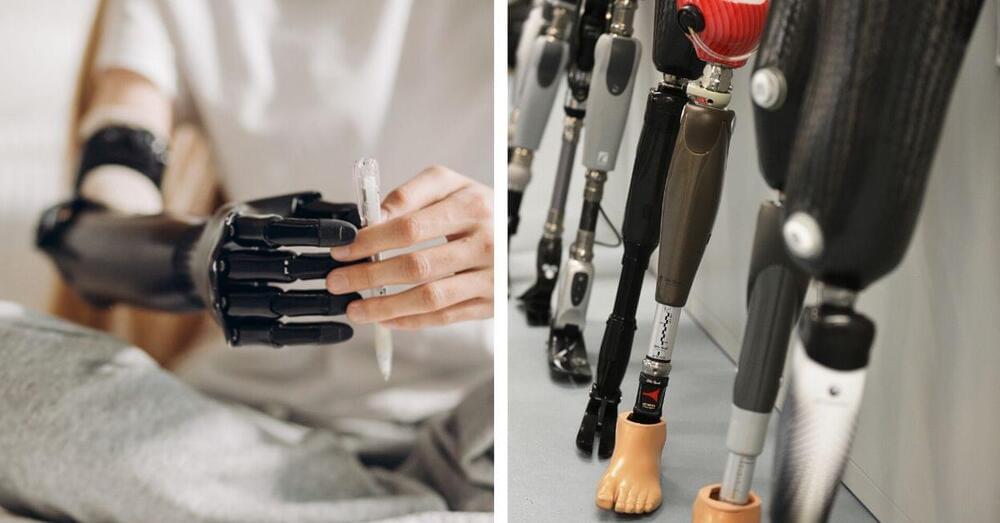

Called neurotransmitters, these chemicals are the brain’s “natural language,” said Dr. Benhui Hu at Nanjing Medical University in China. An artificial neuron using a chemical language could, in theory, easily tap into neural circuits—to pilot a mouse’s leg, for example, or build an entirely new family of brain-controlled prosthetics or neural implants.

A new study led by Hu and Dr. Xiaodong Chen at Nanyang Technological University, Singapore, took a lengthy stride towards seamlessly connecting artificial and biological neurons into a semi-living circuit. Powered by dopamine, the setup wasn’t a simple one-way call where one component activated another. Rather, the artificial neuron formed a loop with multiple biological counterparts, pulsing out dopamine while receiving feedback to change its own behavior.