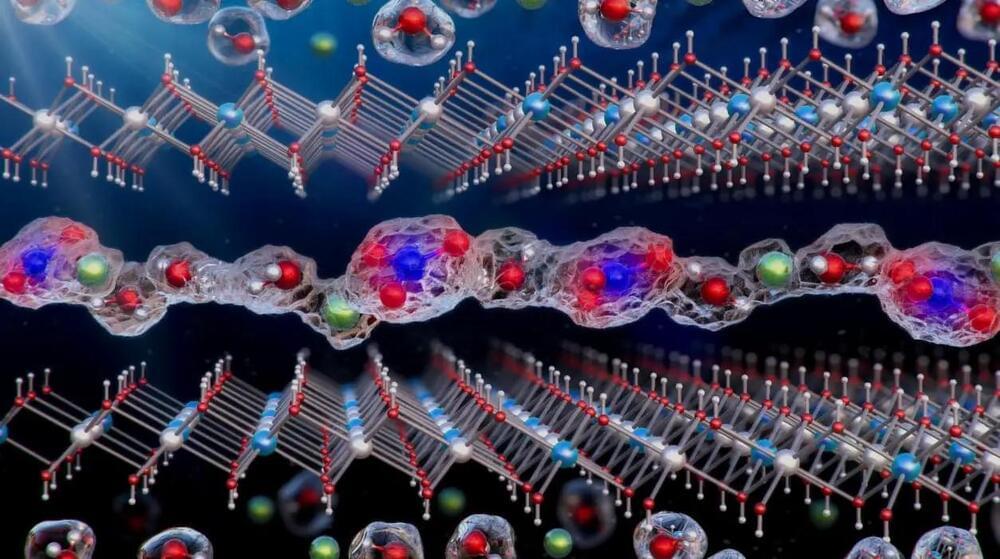

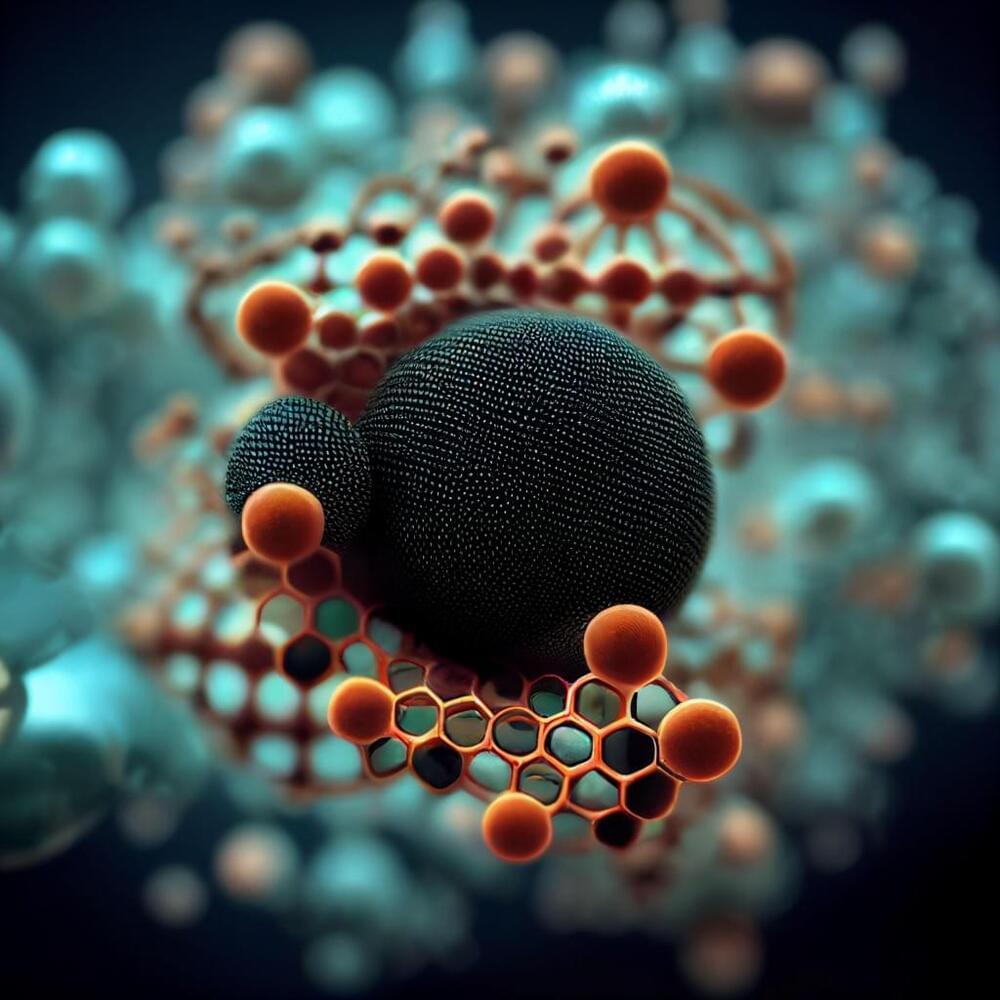

Studying the relationship between the arrangement of water molecules incorporated into layered materials like clays and the arrangement of ions within these materials has been a difficult experiment to conduct.

However, researchers have now succeeded in observing these interactions for the first time by utilizing a technique commonly used for measuring extremely small masses and molecular interactions at the nanoscale.

The nanoscale refers to a length scale that is extremely small, typically on the order of nanometers (nm), which is one billionth of a meter. At this scale, materials and systems exhibit unique properties and behaviors that are different from those observed at larger length scales. The prefix “nano-” is derived from the Greek word “nanos,” which means “dwarf” or “very small.” Nanoscale phenomena are relevant to many fields, including materials science, chemistry, biology, and physics.