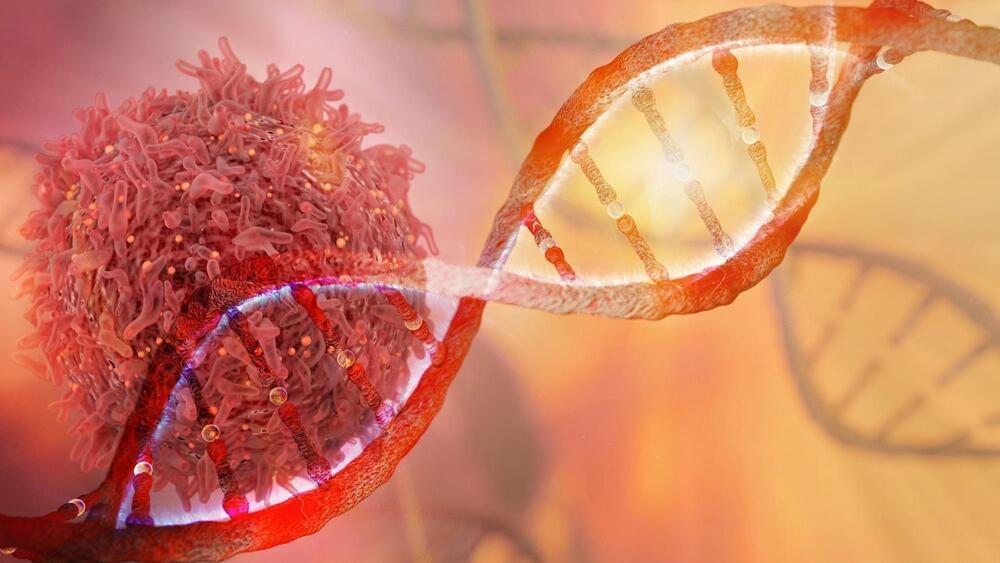

AI can also be of benefit in the diagnosis and treatment of patients. Tools have been created that help diagnose a patient as well as a human would.

AI isn’t a new technology—it’s been researched and developed since the 1950s and is currently present in many of our daily routines. Most of these applications are so common that we don’t even notice them.

Our lives often depend on the healthcare industry. So, having a technology that allows you to speed up patient registration processes and help diagnose more quickly and effectively is essential. Every health center should consider the use of AI for the benefit of its processes so it can adapt to the modern world and its accelerated pace.