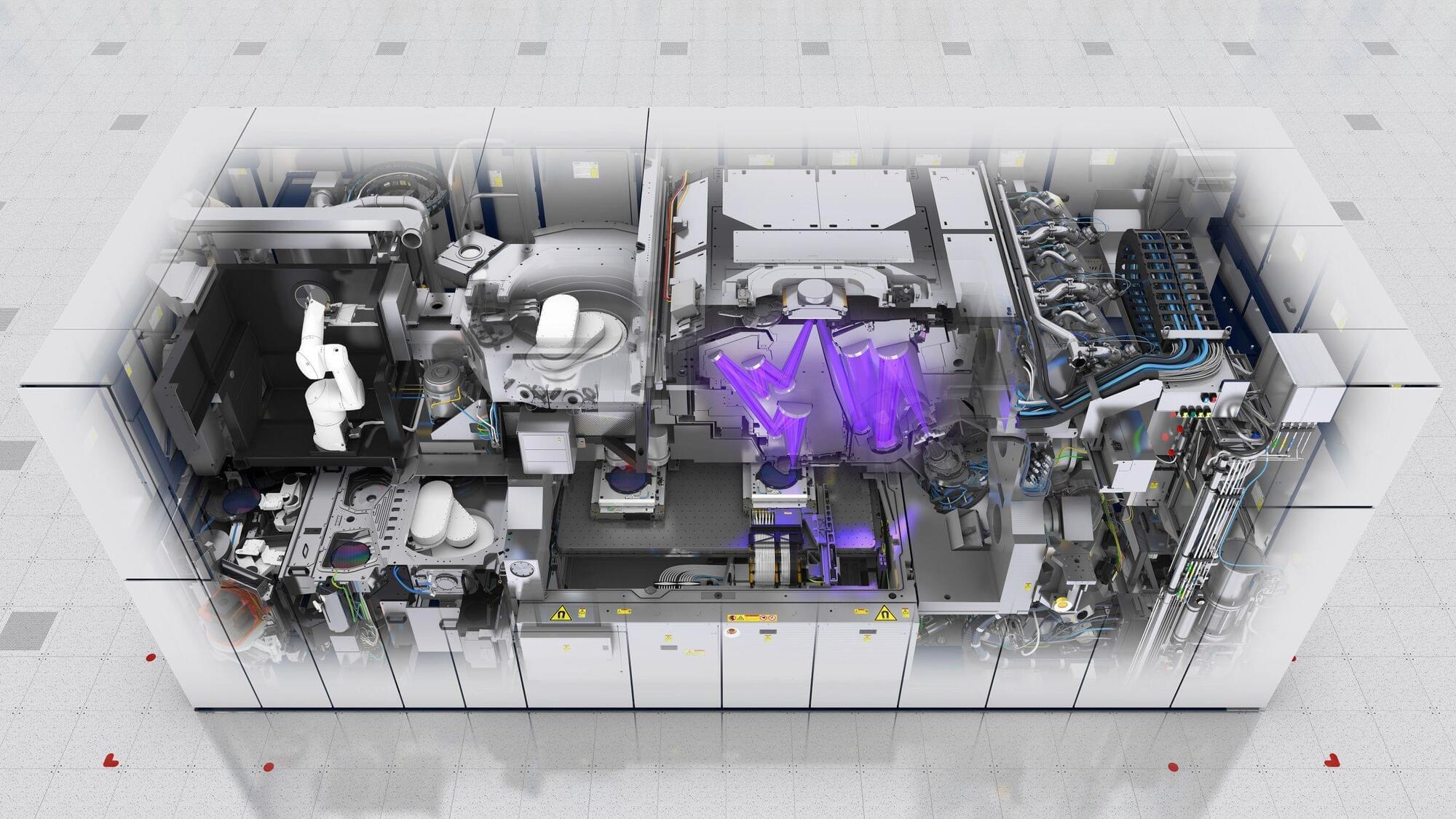

TSMC is also exploring the possibility of applying similar dynamic energy control mechanisms to other lithography equipment, including DUV scanners, as well as additional modules outside the lithography sector.

While TSMC did not reveal what, exactly, its EUV Dynamic Energy Saving Program involves, that it is applicable to DUV systems and other machinery means that it does not exploit EUV-specific peculiarities. For example, the program could implement adaptive power scaling based on real-time operational status. If wafers are not queued for immediate processing, the EUV tool could intelligently pause or shift to a low-power state rather than continuously consume full power. Such an approach would require real-time data exchange across the cleanroom as well as optimizations on process/production flow levels (though, we are speculating).

TSMC has been increasing the power efficiency of its EUV fab tools — which are notorious for their power consumption — for years, now. In mid-2024, the company announced that it had though without disclosing what exactly had been done…