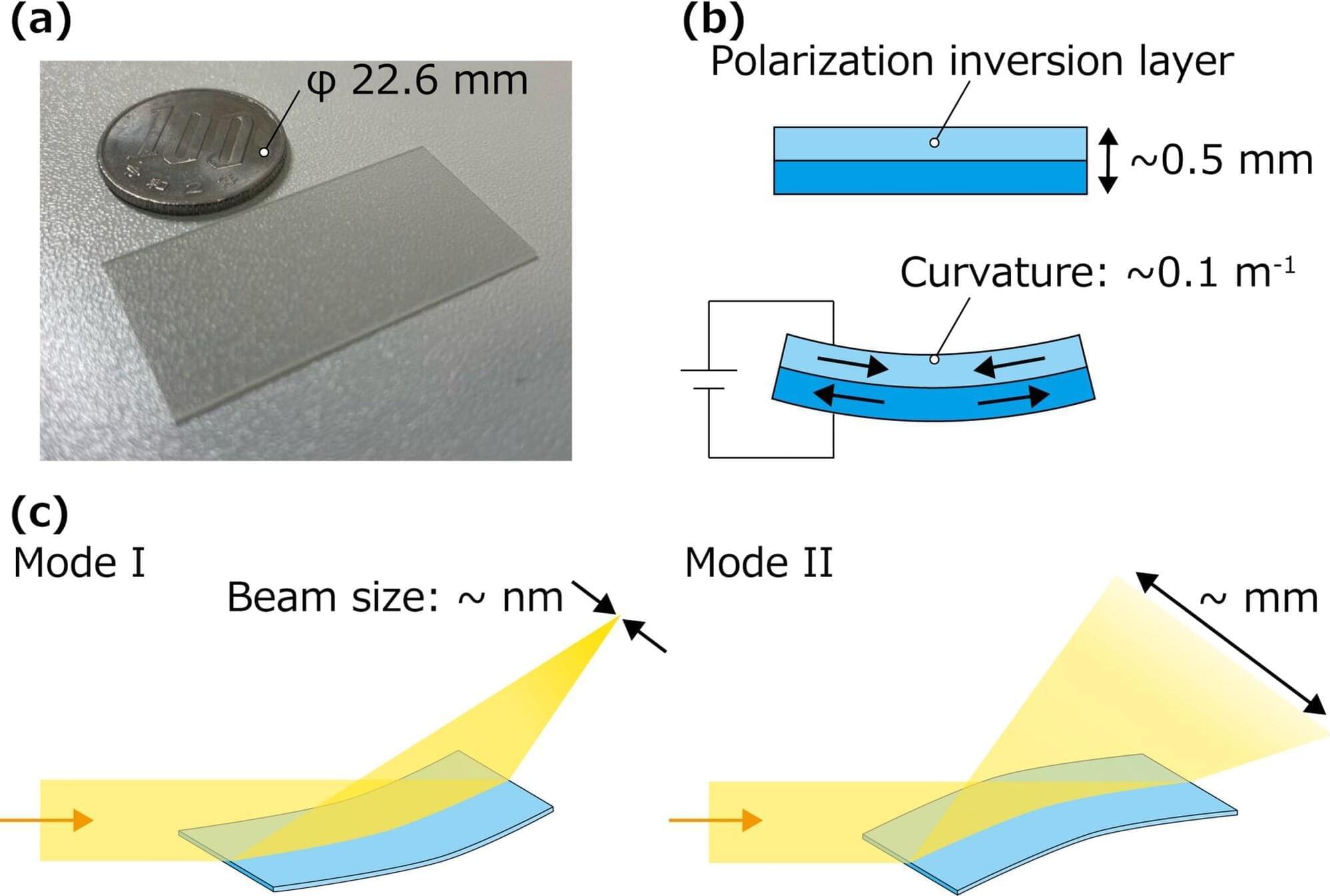

Using only a single-crystal piezoelectric thin wafer of lithium niobate (LN) instead of the usual two-part structure, a group from Nagoya University in Japan has created a deformable mirror that changes X-ray beam size by more than 3,400 times. This improved tuning range enhances both imaging and analysis, especially for the X-rays used in industry.

Their technique is based on LN, a material that has piezoelectricity, meaning that it changes its surface shape in response to voltage. Traditional X-ray mirrors are rigid and resistant to being deformed, making it difficult to adapt them to changing experimental conditions in real time, but the new technique can significantly change beam size, making it useful for a range of situations encountered in industry.

The study is published in the journal Scientific Reports.