A new artificial intelligence system pinpoints the origin of 3D printed parts down to the specific machine that made them. The technology could allow manufacturers to monitor their suppliers and manage their supply chains, detecting early problems and verifying that suppliers are following agreed upon processes.

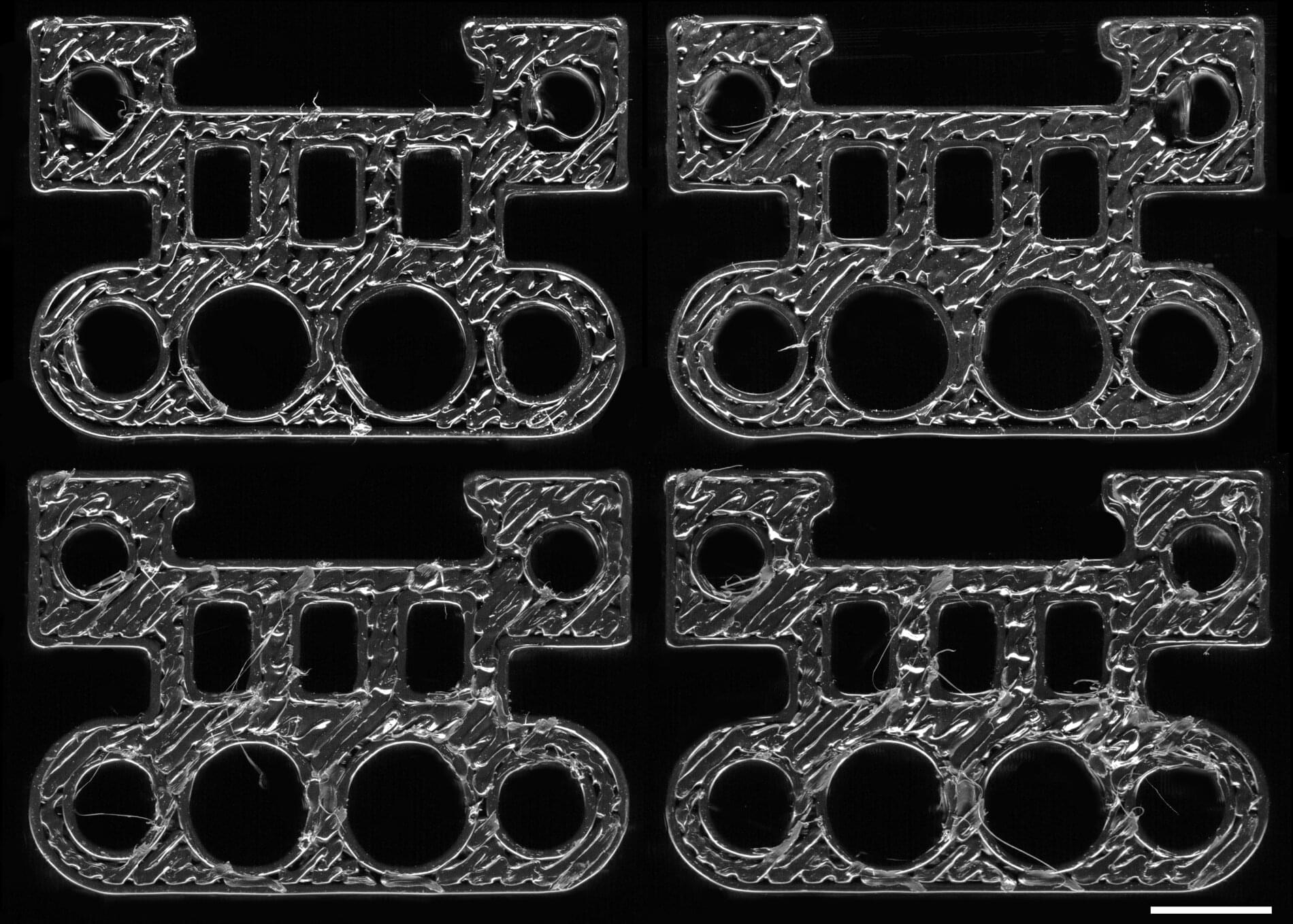

A team of researchers led by Bill King, a professor of mechanical science and engineering at the University of Illinois Urbana-Champaign, has discovered that parts made by additive manufacturing, also known as 3D printing, carry a unique signature from the specific machine that fabricated them. This inspired the development of an AI system which detects the signature, or “fingerprint,” from a photograph of the part and identifies its origin.

“We are still amazed that this works: we can print the same part design on two identical machines –same model, same process settings, same material—and each machine leaves a unique fingerprint that the AI model can trace back to the machine,” King said. “It’s possible to determine exactly where and how something was made. You don’t have to take your supplier’s word on anything.”