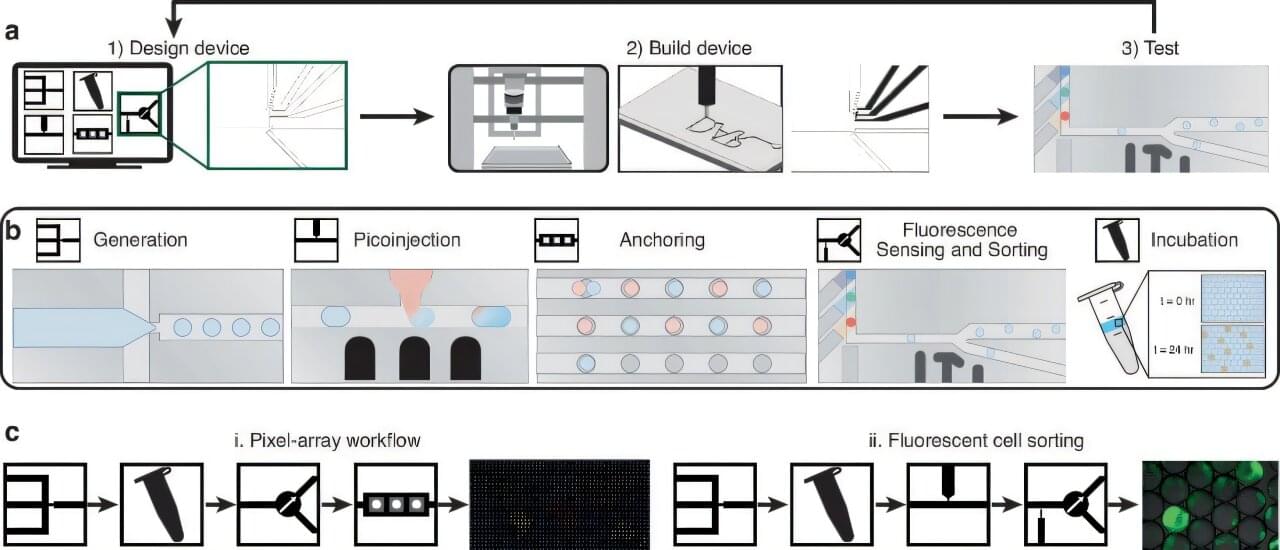

Researchers have developed a freely available droplet microfluidic component library, which promises to transform the way microfluidic devices are created. This innovation, based on low-cost rapid prototyping and electrode integration, makes it possible to fabricate microfluidic devices for under $12 each, with a full design-build-test cycle completed within a single day. The components are biocompatible, high-throughput, and capable of performing multistep workflows, such as droplet generation, sensing, sorting, and anchoring, all critical for automating microfluidic design and testing.

Microfluidics, particularly droplet-based systems, has become a promising technology for diverse fields, including protein engineering, single-cell sequencing, and nanoparticle synthesis. However, the traditional methods of fabricating microfluidic devices —typically using PDMS (polydimethylsiloxane)—are time-consuming and costly, often requiring cleanroom facilities or external vendors.

While alternatives like laser cutting and 3D printing have been explored, these methods often suffer from limitations in resolution, material compatibility, and scalability. As a result, there has been an urgent need for a more efficient, cost-effective, and accessible fabrication method to help propel innovation in microfluidic technology.