How can programmed failure protocols help improve sheet-based fluidic devices, the latter of which have become a cornerstone in enhancing soft robotics worldwide? This is what a recent study published in Cell Reports Physical Science hopes to address as an international team of researchers have developed a method for overcoming common failures of sheet-based systems, specifically due to their lightweight and flexible characteristics. This study has the potential to help engineers develop more efficient sheet-based devices, resulting in improved soft robotics designs.

For the study, the researchers examined how pressure changes could damage heat-sealable textiles that are used in sheet-based devices. Once they determined specific failure thresholds, the team incorporated programmed failures into the design, enabling the device to determine specific failure points and prevent further damage.

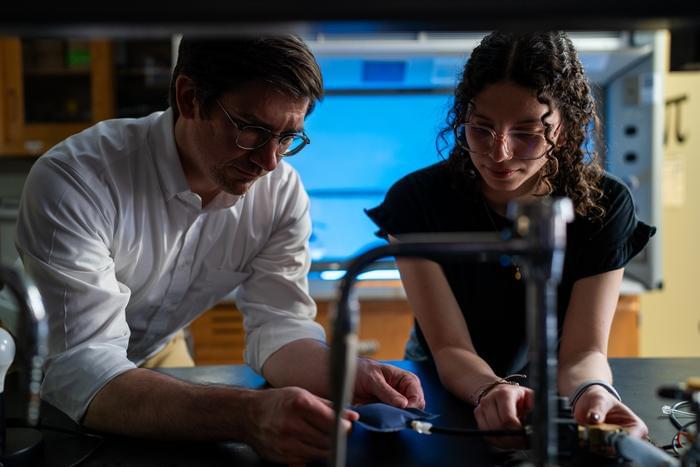

“Put simply, we are making soft, flexible machines smarter by designing their internal components to fail intentionally in a well-understood manner,” said Dr. Daniel J. Preston, who is an assistant professor of mechanical engineering at Rice University and a co-author on the study. “In doing so, the resulting systems can recover from pressure surges and even complete multiple tasks using a single control input.” Going forward, the team hopes their research will lead to improved sheet-based fluidic systems, which, as noted, have become a cornerstone of soft robotics.