The same material from which you drink your morning coffee could transform the way scientists detect disease, purify water, and insulate space shuttles thanks to an entirely new approach to ceramic manufacturing.

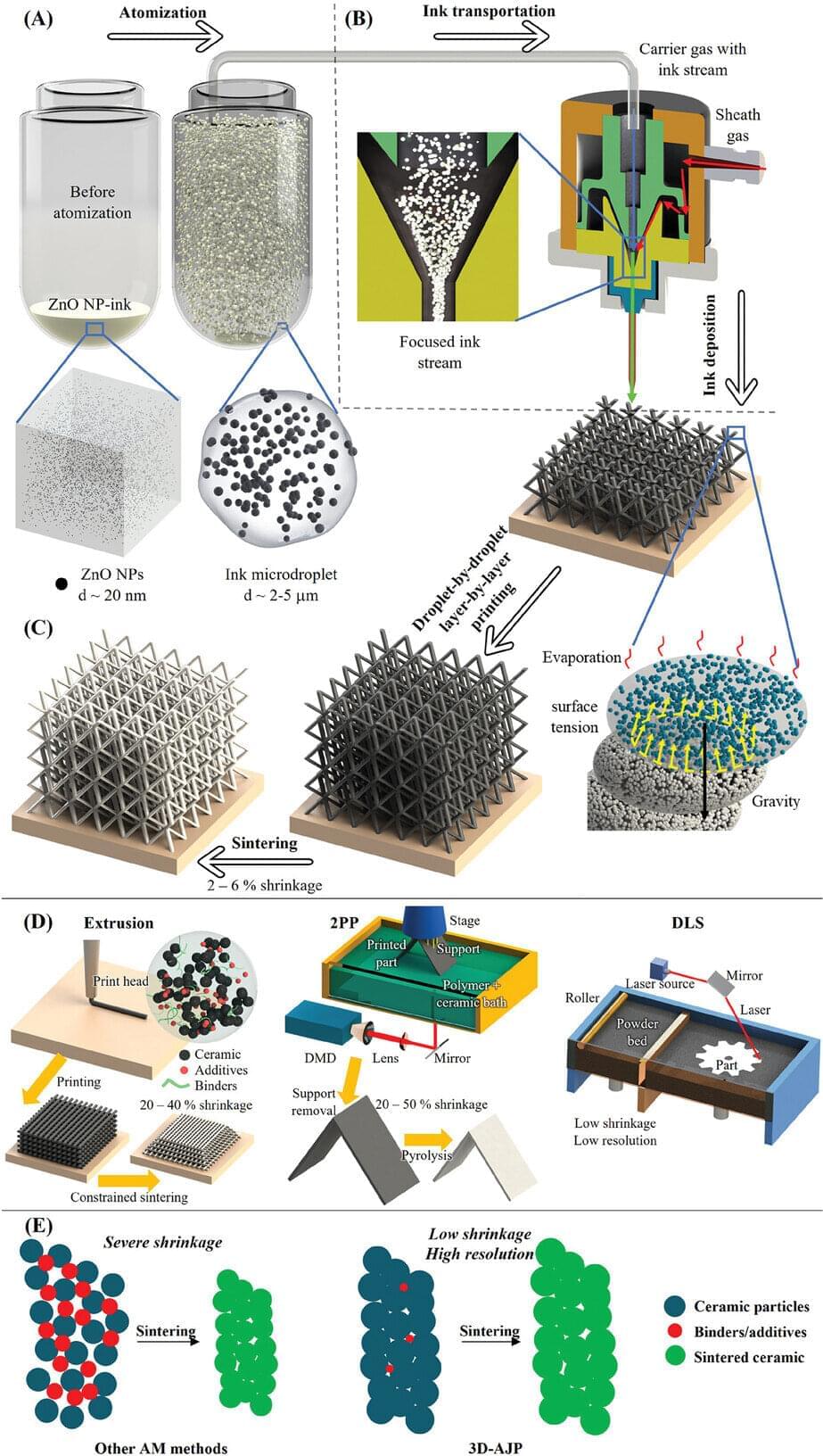

Published in Advanced Science, 3D-AJP is an aerosol jet 3D nanoprinting technique that allows for the fabrication of highly complex ceramic structures that—at just 10 micrometers (a fraction of the width of human hair)—are barely visible to the naked eye. These 3D structures are made up of microscale features including pillars, spirals, and lattices that allow for controlled porosity, ultimately enabling advances in ceramic applications.

“It would be impossible to machine ceramic structures as small and as precise as these using traditional manufacturing methods,” explained Rahul Panat, professor of mechanical engineering at Carnegie Mellon University and the lead author of the study. “They would shatter.”