Theorists predict that the melting of a crystalline solid happens in three stages. First, a liquid film forms on the surface. Second, defects between neighboring crystallites fluidize, causing the crystal to lose its rigidity. And third, the remaining solid parts liquefy. Researchers have observed the first and third stages of this melting process but not, until now, the second. By measuring how laser light scatters off heated crystalline tin samples, Emil Polturak and Steve Lipson of Technion–Israel Institute of Technology have detected changes in the samples’ shape that they show correspond to the melting of defects known as grain boundaries [1]. The study provides an optical tool for examining melting stages in metallic crystals.

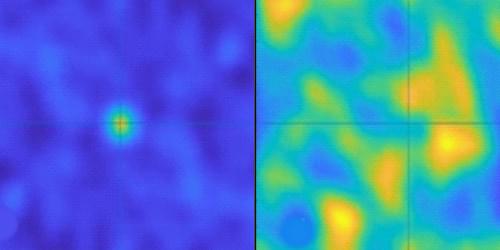

For their demonstration, Polturak and Lipson placed a 1-mm-thick tin sample inside a sealed chamber and directed a green laser beam at its surface. They then heated the sample from 175 o C to 232 o C—the bulk melting point of tin—while taking snapshots of the light that scattered off the sample’s surface. The duo then used these snapshots to search for changes in the profile of the surface as the sample melted.

Up to 224 o C, pairs of sequential images were close to identical. This correlation decreased by nearly 50% at 225 o C—the temperature predicted for the onset of grain-boundary melting in tin. Polturak and Lipson say that once boundaries become fluid, grains can reorient themselves to change the sample’s volume and shape, which can impact its surface profile. Being able to observe and distinguish the three stages of melting could improve models of melting—a phenomenon that, despite its ubiquity, Polturak and Lipson say remains a “work in progress” in terms of understanding.