Researchers from EPFL have resolved a long-standing debate surrounding laser additive manufacturing processes with a pioneering approach to defect detection.

The progression of laser additive manufacturing —which involves 3D printing of metallic objects using powders and lasers—has often been hindered by unexpected defects. Traditional monitoring methods, such as thermal imaging and machine learning algorithms, have shown significant limitations. They often either overlook defects or misinterpret them, making precision manufacturing elusive and barring the technique from essential industries like aeronautics and automotive manufacturing.

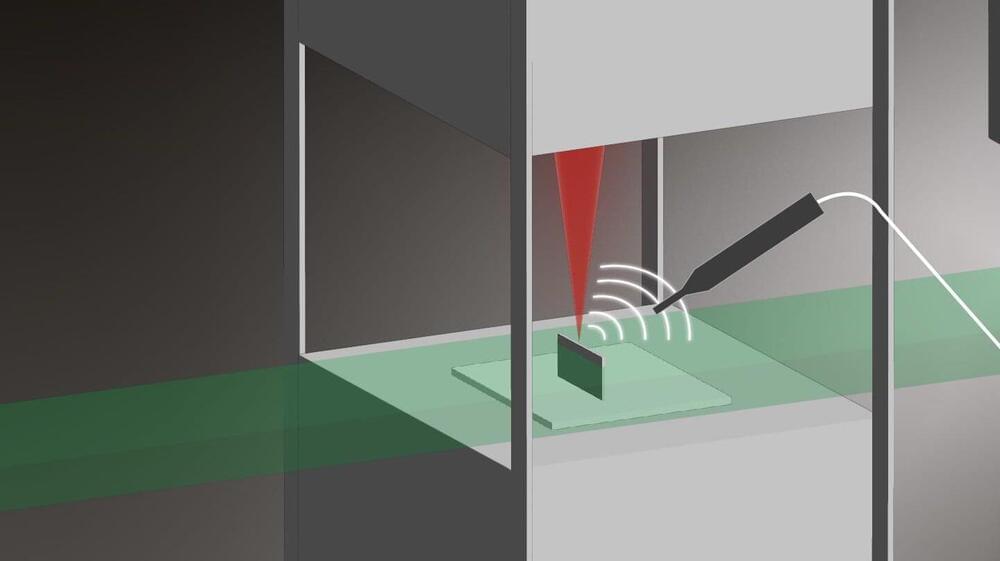

But what if it were possible to detect defects in real-time based on the differences in the sound the printer makes during a flawless print and one with irregularities? Up until now, the prospect of detecting these defects this way was deemed unreliable. However, researchers at the Laboratory of Thermomechanical Metallurgy (LMTM) at EPFL’s School of Engineering have successfully challenged this assumption.