Following the path of electronic integrated circuits (EICs), silicon (Si) photonics holds promises to enable photonic integrated circuits (PICs) with high densities, advanced functionality and portability. Although various Si photonics foundries are rapidly developing PIC capabilities—enabling volume production of modulators, photodetectors and most recently lasers—Si PICs have yet to achieve the stringent requirements on laser noise and overall system stability imposed by many applications such as microwave oscillators, atomic physics and precision metrology9,10,11. Semiconductor lasers must strongly suppress amplified-spontaneous-emission noise to achieve narrow linewidth for these applications12. They will also require isolation from the rest of the optical system, otherwise the laser source will be sensitive to back-reflections from downstream optical components that are beyond the control of the PIC designer13. In many integrated photonic solutions, a bulk optical isolator must be inserted between the laser chip and the rest of the system, significantly increasing the complexity, as well as the cost of assembly and packaging14.

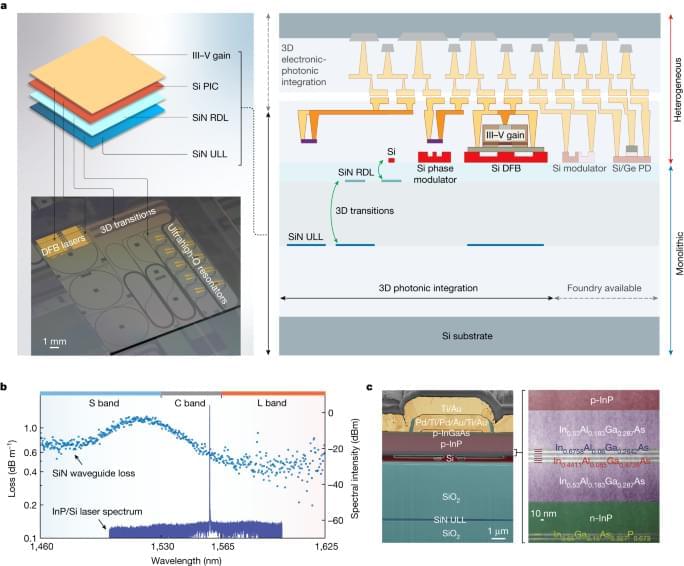

To enrich the capabilities of Si PICs and avoid multi-chip optical packaging, non-group-IV materials need to be heterogeneously integrated to enable crucial devices, including high-performance lasers, amplifiers and isolators15,16,17. It has now been widely acknowledged that group III–V materials are required to provide efficient optical gain for semiconductor lasers and amplifiers in Si photonics regardless of the integration architecture, but concerns still remain for a complementary metal–oxide–semiconductor (CMOS) fab to incorporate magnetic materials, which are currently used in industry-standard optical isolators18.

Fortunately, a synergistic path towards ultralow laser noise and low feedback sensitivity exists—using ultrahigh-quality-factor (Q) cavities for lasers that not only reduce the phase noise but also enhance the feedback tolerance to downstream links. These effects scale with the cavity Q and ultrahigh–Q cavities would thus endow integrated lasers with unprecedented coherence and stability19,20. The significance is twofold. First, the direct integration of ultralow-noise lasers on Si PICs without the need for optical isolators simplifies PIC fabrication and packaging. Furthermore, this approach does not introduce magnetic materials to a CMOS fab as isolators are not obligatory for such complete PICs.