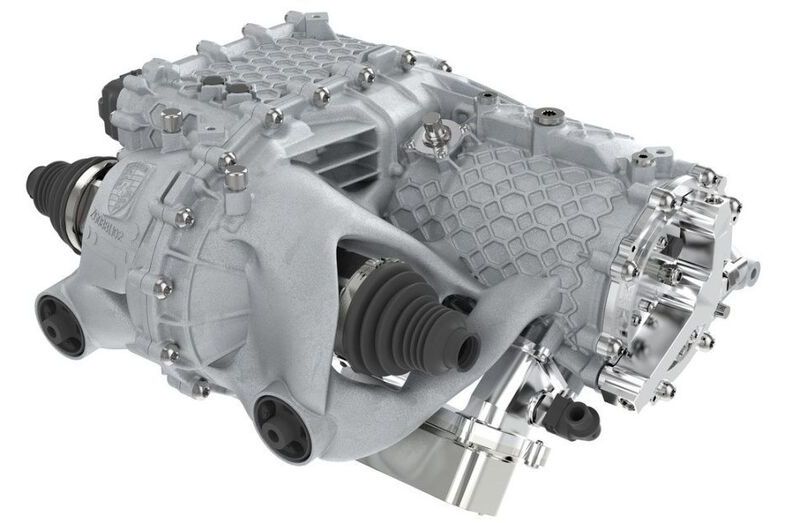

In December, Porsche announced that it had been 3D printing prototype housings for electric drives that were stronger, lighter, and much quicker to manufacture. The engine-gearbox units produced using this method were even able to pass all of the company’s quality and stress tests without issue.

Porsche manufactures the housings using a 3D printing method called laser metal fusion, which entails a laser beam heating and melting a powder surface depending on the desired contours. This method allows Porsche to produce an engine gearbox that is both 10% lighter and 100% stronger because of the inherent lattice structures.

Another significant upside to manufacturing parts this way is the ease and speed of creating new components or making changes to existing ones. For example, an entirely new part can be designed and then physically printed very quickly with no need to do things such as create new tooling to manufacture the part.