“FUJIFILM Corporation (President: Kenji Sukeno) is pleased to announce that it has achieved the world’s record 317 Gbpsi recording density with magnetic tapes using a new magnetic particle called Strontium Ferrite (SrFe)*4. The record was achieved in tape running test, conducted jointly with IBM Research. This represents the development of epoch-making technology that can produce data cartridges with the capacity of 580TB (terabytes), approximately 50 times greater than the capacity of current cartridges*5. The capacity of 580TB is enough to store data equivalent to 120000 DVDs.”

TOKYO, December 162020 — FUJIFILM Corporation (President: Kenji Sukeno) is pleased to announce that it has achieved the world’s record 317 Gbpsi recording density with magnetic tapes using a new magnetic particle called Strontium Ferrite (SrFe) *4. The record was achieved in tape running test, conducted jointly with IBM Research. This represents the development of epoch-making technology that can produce data cartridges with the capacity of 580TB (terabytes), approximately 50 times greater than the capacity of current cartridges *5. The capacity of 580TB is enough to store data equivalent to 120000 DVDs.

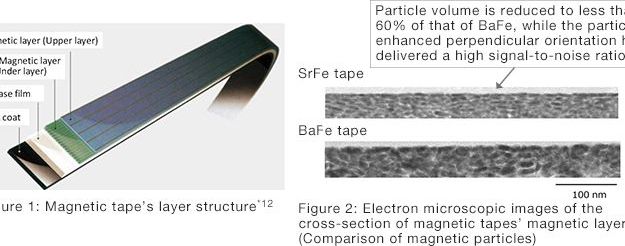

SrFe is a magnetic material that has very high magnetic properties and is stable to maintain high performance even when processed into fine particles. It is widely used as a raw material for producing magnets for motors. Fujifilm has applied its proprietary technology to successfully develop ultra-fine SrFe magnetic particles, which can be used as a magnetic material for producing particulate magnetic tape media for data storage. The company has been conducting R&D for commercial use of SrFe magnetic particles as potential replacement of Barium Ferrite (BaFe) magnetic particles, currently used in magnetic tape data storage media. Magnetic tapes used in this test have been produced at the company’s existing coating facility, confirming the ability to support mass production and commercialization.

The amount of data in the society is exponentially increasing due to the introduction of high-definition 4K / 8K video, advancement in IoT / ICT, and the proliferation of Big Data analysis. “Cold Data,” or data that was generated a long time ago and rarely accessed, is said to account for over 80% of all data available today. There is a fast-growing trend of utilizing such Cold Data and other accumulated data, creating the need to secure safe, affordable and long-term data storage. Magnetic tapes have been used by major data centers and research organizations for many years as they not only offer benefits including large storage capacity, low cost and long-term storage performance, but also create air gap data protection, physically isolated from the network, thereby minimizing the risk of data damage or loss caused by cyberattacks.