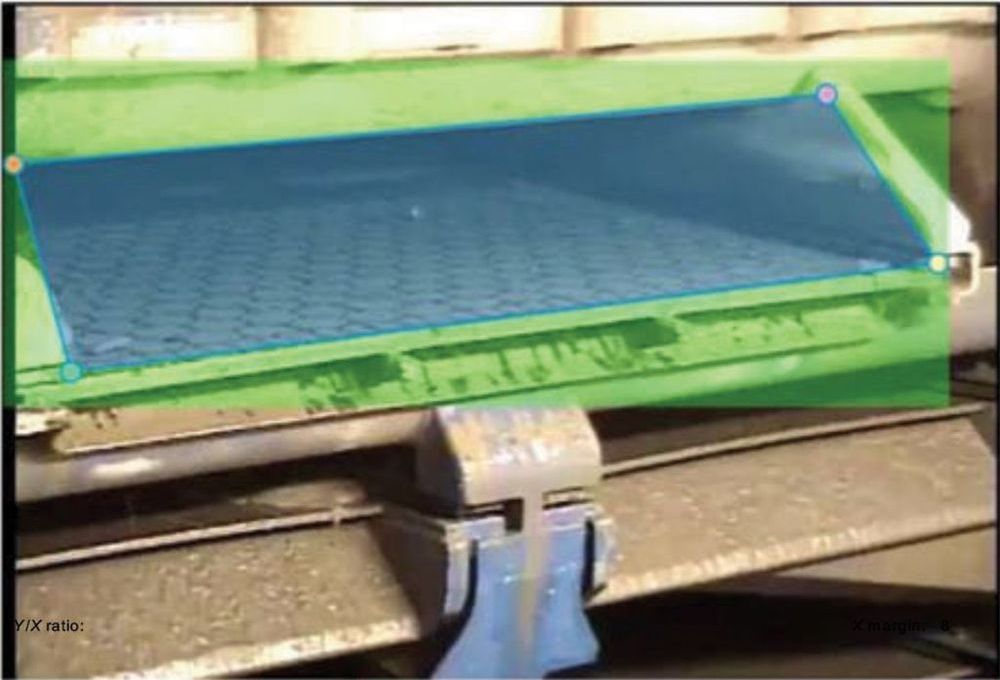

A real-time deep-learning model is proposed to classify the volume of cuttings from a shale shaker on an offshore drilling rig by analyzing the real-time monitoring video stream. As opposed to the traditional, time-consuming video-analytics method, the proposed model can implement a real-time classification and achieve remarkable accuracy. The approach is composed of three modules. Compared with results manually labeled by engineers, the model can achieve highly accurate results in real time without dropping frames.

Introduction

A complete work flow already exists to guide the maintenance and cleaning of the borehole for many oil and gas companies. A well-formulated work flow helps support well integrity and reduce drilling risks and costs. One traditional method needs human observation of cuttings at the shale shaker and a hydraulic and torque-and-drag model; the operation includes a number of cleanup cycles. This continuous manual monitoring of the cuttings volume at the shale shaker becomes the bottleneck of the traditional work flow and is unable to provide a consistent evaluation of the hole-cleaning condition because the human labor cannot be available consistently, and the torque-and-drag operation is discrete, containing a break between two cycles.