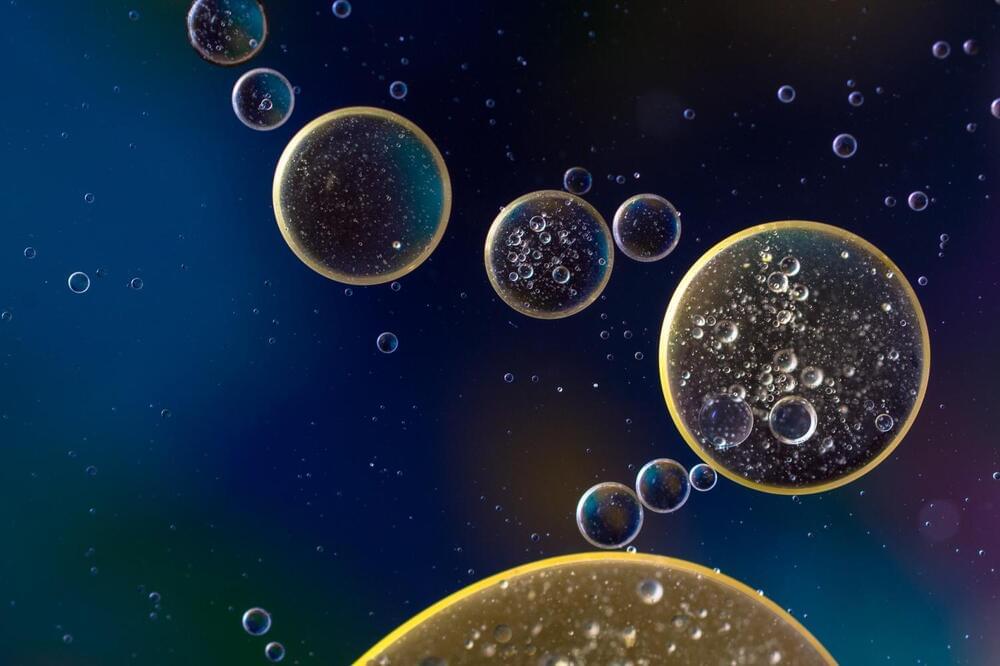

Wastewater samples are being used to track the spread of SARS-CoV-2.

It’s sometimes called ‘wastewater-based epidemiology’ (WBE) – a scientific and public health field that involves detecting and monitoring specific molecules in untreated wastewater, to determine how prevalent they are. First proposed more than 70 years ago as a way to track the spread of the deadly poliovirus, WBE has since been used to measure human population exposure to pollutants, and even to estimate the level of drug consumption in major cities. In 2,020 it hit global news headlines when it was first proposed as a way to track SARS-CoV-2, the virus that causes COVID-19.