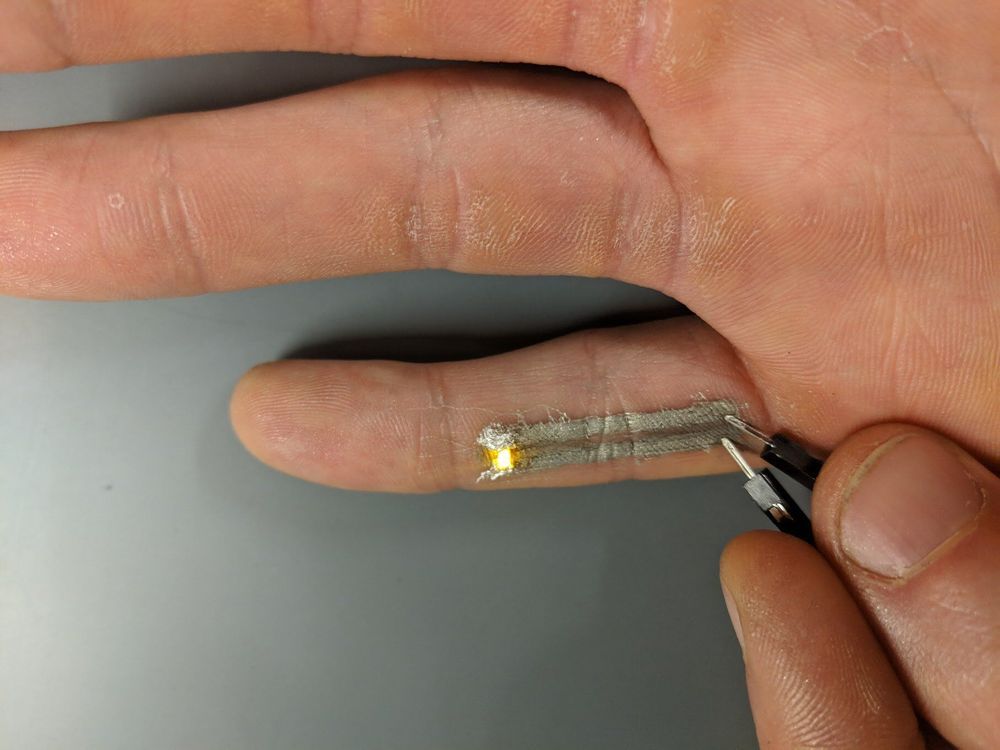

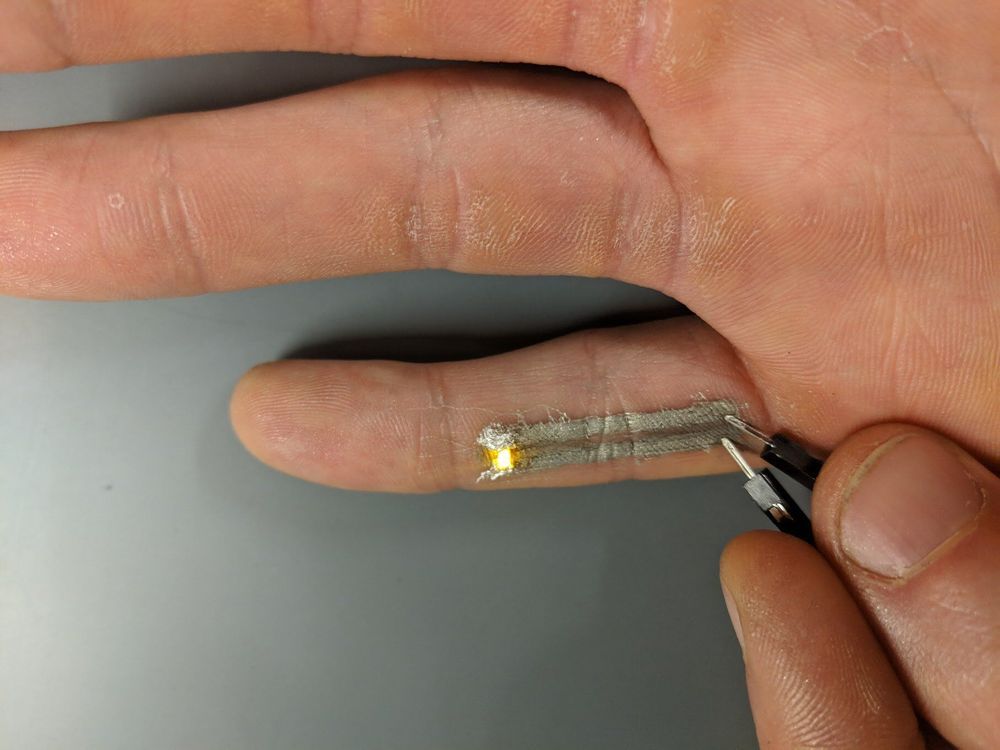

Electrical engineers at Duke University have devised a fully print-in-place technique for electronics that is gentle enough to work on delicate surfaces including paper and human skin. The advance could enable technologies such as high-adhesion, embedded electronic tattoos and bandages tricked out with patient-specific biosensors.

The techniques are described in a series of papers published online July 9 in the journal Nanoscale and on October 3 in the journal ACS Nano.

“When people hear the term ‘printed electronics,’ the expectation is that a person loads a substrate and the designs for an electronic circuit into a printer and, some reasonable time later, removes a fully functional electronic circuit,” said Aaron Franklin, the James L. and Elizabeth M. Vincent Associate Professor of Electrical and Computer Engineering at Duke.