Dr. Jung-Dae Kwon’s research team at the Energy & Environmental Materials Research Division of the Korea Institute of Materials Science (KIMS) has successfully developed an amorphous silicon optoelectronic device with minimal defects, even using a low-temperature process at 90°C. The findings are published in the journal Advanced Science.

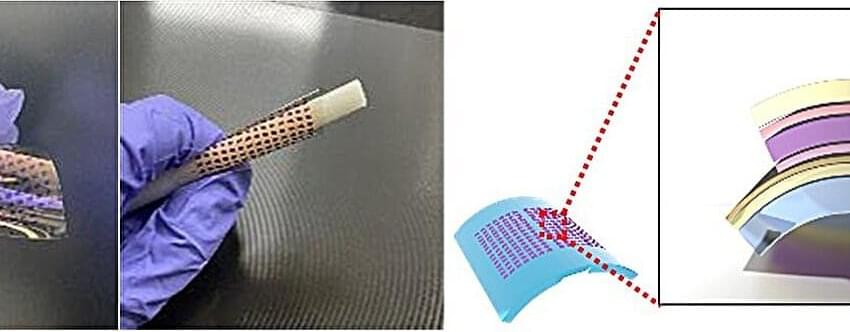

Notably, the team overcame the limitations of high-temperature processing by precisely controlling the hydrogen dilution ratio—the ratio of hydrogen to silane (SiH4) gas—enabling the fabrication of high-performance flexible optoelectronic devices (sensors that detect light and convert it into electrical signals).

Flexible optoelectronic devices are key components of next-generation electronic devices, such as wearable electronics and image sensors, and require the precise deposition of thin films on thin, bendable substrates. However, a major limitation has been the necessity of high-temperature processing above 250°C, making it difficult to apply these devices to heat-sensitive flexible substrates.