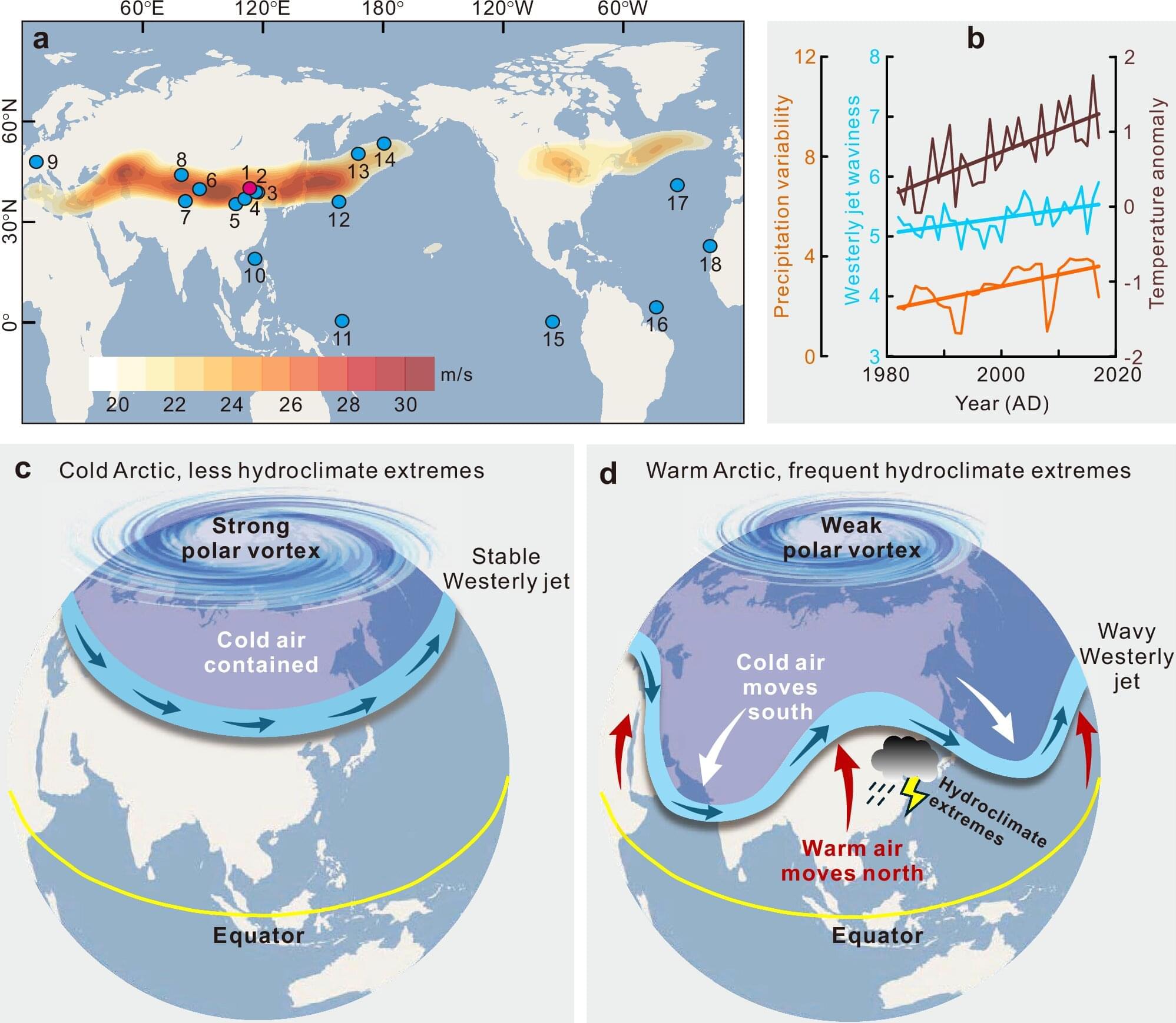

In recent years, the global climate has become increasingly extreme, with intensifying alternations of droughts and floods—particularly in ecologically vulnerable mid-latitude regions. But what is driving this hydroclimatic variability? Scientists have long debated the underlying mechanisms.

A research team led by Prof. Long Hao from the Nanjing Institute of Geography and Limnology of the Chinese Academy of Sciences, drilled a 300.8-meter-long lacustrine sediment core in the Datong Basin of Shanxi Province, located in mid-latitude East Asia (Northern China). By reconstructing more than 5.7 million years of Earth’s history, the researchers revealed that the “waviness” of the westerly jet stream is the primary driver of mid-latitude climate variability. The study was recently published in Nature Communications.

This sediment core acts as a detailed “climate archive,” documenting precipitation changes over approximately 5.7 million years—spanning the Pliocene and Pleistocene epochs. By analyzing chemical indicators within the core, the researchers obtained a high-resolution record of ancient precipitation patterns.