It enables us to make extraordinary leaps of imagination.

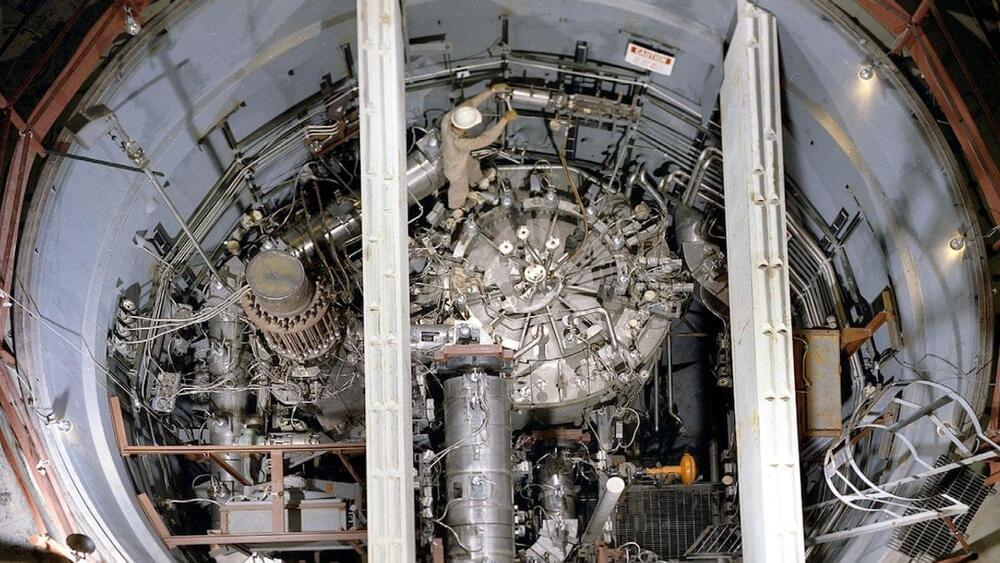

We all have to make hard decisions from time to time. The hardest of my life was whether or not to change research fields after my Ph.D., from fundamental physics to climate physics. I had job offers that could have taken me in either direction — one to join Stephen Hawking’s Relativity and Gravitation Group at Cambridge University, another to join the Met Office as a scientific civil servant.

I wrote down the pros and cons of both options as one is supposed to do, but then couldn’t make up my mind at all. Like Buridan’s donkey, I was unable to move to either the bale of hay or the pail of water.

Metamorworks/iStock.

Since it was doing my head in, I decided to try to forget about the problem for a couple of weeks and get on with my life. In that intervening time, my unconscious brain decided for me. I simply walked into my office one day and the answer had somehow become obvious: I would make the change to studying the weather and climate.