All mammals hold a backup copy of cellular youth, a new study says. All we have to do is trigger the switch to turn back the clock, researchers say.

Watch this Hyundai crab walk. Imagine the ease getting in and out of curbside parking.

Hyundai Mobis presents a IONIQ 5 with the e-Corner Module (In-wheel System).

You can see the real-life motions of crab driving and zero turn.

There will be.

1) No Engine.

2) No Traditional Chassis.

3) No Steering Column.

Source : Hyundai Mobis.

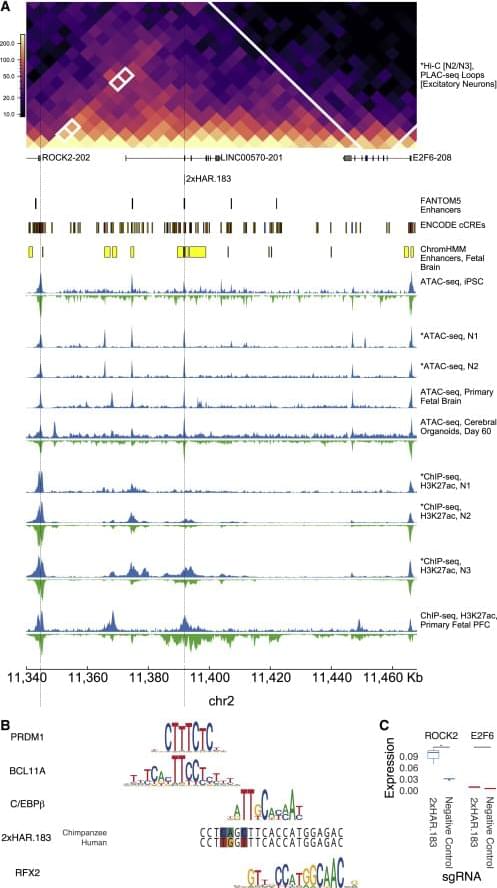

Whalen et al. couple deep learning with functional assays in chimpanzee and human cells to interrogate the neurodevelopmental enhancer potential of 2,645 human accelerated regions (HARs). Activity is dominated by cis rather than trans effects, and compensatory changes are identified as a driver of rapid HAR evolution.

Could the advancement of ‘Non Player Character’ tech give us a glimpse of being able to bersion ourselves?

Over the last decade, the landscape of machine learning software development has undergone significant changes. Many frameworks have come and gone, but most have relied heavily on leveraging Nvidia’s CUDA and performed best on Nvidia GPUs. However, with the arrival of PyTorch 2.0 and OpenAI’s Triton, Nvidia’s dominant position in this field, mainly due to its software moat, is being disrupted.

This report will touch on topics such as why Google’s TensorFlow lost out to PyTorch, why Google hasn’t been able to capitalize publicly on its early leadership of AI, the major components of machine learning model training time, the memory capacity/bandwidth/cost wall, model optimization, why other AI hardware companies haven’t been able to make a dent in Nvidia’s dominance so far, why hardware will start to matter more, how Nvidia’s competitive advantage in CUDA is wiped away, and a major win one of Nvidia’s competitors has at a large cloud for training silicon.

Join Our Discord to enter the giveaway (and comment with your username (without the at!)): https://discord.gg/learnaitogether.

Attend WAICF with a 20% discount: https://www.worldaicannes.com/pass/executive-pass/?utm_campa…ICF23-LOBO

References:

►Read the full article: https://www.louisbouchard.ai/vall-e/

►Link for the audio samples: https://valle-demo.github.io/

►Wang et al., 2023: VALL-E. https://arxiv.org/pdf/2301.02111.pdf.

►My Newsletter (A new AI application explained weekly to your emails!): https://www.louisbouchard.ai/newsletter/

Chapters:

0:00 Hey guys, we are going to host tons of cool (and free) events on Discord, join us!

1:01 VALLE

6:09 Giveaway (and how to participate)

#deepfake #artificialintelligence #VALLE

Cardiovascular disease (CVD) is the #1 cause of death globally and encompasses a broad set of over a dozen disorders that compromise the function of the heart and blood vessels. The major cause of CVD by far, however, is the pathological process of (CDC, 2022). Like the accumulation of rust within pipes, involves the gradual build up of plaque within arteries which compromises the flow of blood and oxygen in the body. Strikingly, is responsible for more than 40% of all deaths worldwide, and 80% of those deaths are in individuals 65 years and older. This includes mortality from devastating pathologies that are among the leading causes of death like coronary artery disease, chronic obstructive pulmonary disorder and stroke (Pahwa, 2022).

“AI needs to be fair and ethical for everyone,” said lawyer/programmer Matthew Butterick. “But Stability AI, Midjourney, and DeviantArt are appropriating the work of thousands of artists with no consent, no credit, and no compensation. As a lawyer who is also a longtime member of the visual-arts community, it’s a pleasure to stand up on behalf of fellow artists and continue this essential conversation about how we the people want AI to coexist with human culture and creativity.”

Since its founding in 2000, DeviantArt had grown to be a haven for artists of all stripes. A core aspect of participating in the DeviantArt community for artists is the practice of sharing digital images of their artwork. Today, DeviantArt bills itself as “the world’s largest art community,” hosting millions of images. At the same time, it offers DreamUp, a product that unlawfully infringes on the rights of its own art community. To add insult to injury, a large portion of the training data for Stable Diffusion—which powers DreamUp—was made up of images scraped from DeviantArt without permission from the artists that posted them.

For more information, please see our case page www.saverilawfirm.com/ai-art-generators-copyright-litigation and our case website stablediffusionlitigation.com.