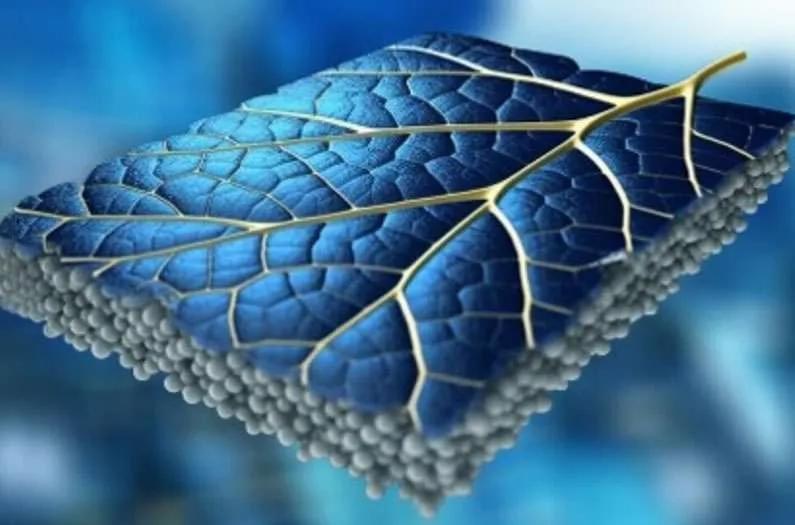

Low-cost, widely available materials cool solar panels without using energy to boost electricity output and produce liters of water at the same time.

The ancient Greek philosopher Aristotle wrote in his manuscript on Physics 2,373 years ago: “If everything that exists has a place, place too will have a place, and so on ad infinitum.” Is the notion of space being continuous ‘without limit’ justified?

Before elementary particles were discovered, water was thought to be a continuous fluid. This is a good approximation on large scales but not on molecular scales where the interactions among elementary particles matter.

Similarly, spacetime has been thought to be a continuum since ancient times. While this notion appears consistent with all experimental data on large spatial or temporal scales, it may not be valid on tiny scales where quantum effects of gravity matter. An analogy can be made with the illusion of a movie which appears continuous when the frame rate is high enough and the spatial pixels are small enough for our brain to process the experience as seamless. Since our brain is made of elementary particles, the temporal and spatial resolution by which it senses reality is coarser by many orders of magnitude than any fundamental scale by which spacetime is discretized.

Why is everyone so worried about teenagers using AI to write their term papers while no one is talking about AI crashing the financial markets? If high school Pat gets an A they didn’t earn that’s one thing, but Megla Corp using AI to corner the stock market and crash the world economy, well that is quite another. I have no proof that large corporations are in a competition to build the perfect trader, the ultimate hedge fund manager, the killer quant, and the optimal analyst all rolled into one ultra-economist AI, but I know, we all know, in our greedy little capitalist hearts, it’s true. This wanna-be hegemonic corporation will have unleashed an economic weapon that can’t be bargained with, can’t be reasoned with, doesn’t feel pity or remorse or fear, and absolutely will not stop… EVER, until you are broke!

The legendary Hedge fund manager Kyle Reese aside, think about the implications of a trading bot that has even just a 2% advantage and how much money that can mean. Casino empires were built on games that have less advantage than that so you are crazy if you don’t think there is a race to build the ultimate TradeGPT. Everyone is looking for an edge because, in a land where money is king, he or she who owns a money printer owns the crown. Wall Street was an early adopter of computers and networks and they got so far out ahead of the regulators that they crashed the market on Black Monday in 1987 dropping the US market almost 25% in a day that sent reverberations around the world.

Now maybe we can snack happily! I think this applies to regular food too? I can eat all the Chinese and Mexican and Italian food I want? Plus for people with genetic risks can’t this not help? I hope so.

Mice fed a high-sugar, high-fat diet for most of their lives managed to escape weight gain and protect their livers when they were treated with an experimental new drug.

The small-molecule drug was developed by a team led by The University of Texas Health Science Center at San Antonio (UT Health San Antonio). K nown by its chemical acronym CPACC, it works by limiting the entry of magnesium into the mitochondria, the parts of the cell in charge of generating energy and burning calories.

Mitochondrial abnormalities have been implicated in a range of diseases, including obesity, diabetes, and cardiovascular disease.

Welcome to this special issue, focusing on the potential of pluripotent stem cell (PSC)-based therapies and their paths toward clinical application. Since the establishment of human embryonic stem (ES) and induced pluripotent stem (iPS) cells in 1998 and 2007, respectively, significant progress has been made in differentiating PSCs into a broad range of somatic cells. We are now closer than ever before to having highly functional PSC-derived somatic cells at purity for transplantation therapies to complement damaged or diseased organs and restore their physiologic functions. Like organ transplantation, PSC-based therapies have the potential to regenerate damaged organs that cannot otherwise be healed by using small-molecule or antibody-based drugs.

In this issue, Kobold et al. present an overview of the history and current status of clinical studies utilizing human PSCs. Since the early 2010s, many clinical studies employing human ES cells have been initiated. By 2018, the number of such studies using human iPS cells had skyrocketed. Many PSC-based therapies are currently being tested to treat various pathologic conditions, including different neoplasms and diseases of the eye, adnexa, and circulatory system. However, there are still many diseases that require further efforts to interrogate the true potential of PSC-based therapies. To advance the use of PSC-based therapy to treat a wider range of pathologic conditions in the future, we must continue with extensive basic and clinical research to establish both efficacy and safety for such new therapies.

Although clinical research on PSC-based therapy for liver diseases has not received as much attention, there is much hope for it to become a real alternative to living-donor liver transplantation. Cardinale et al. provided a comprehensive summary of the recent studies on cell-based therapy for liver diseases. In addition, artificial livers generated through bioengineering efforts are now considered to be a viable option. Aside from traditional cell or organ transplantation to restore impaired liver function, transplantation aimed at treating the microenvironment, such as inflammation, in the liver is also an effective therapeutic strategy. Concurrent research efforts in both basic and clinical studies will be crucial in making PSC-based therapy for liver diseases a reality.

“The definition of the human embryo is far from being engrained, it’s constantly evolving with scientific advances,” said Nicolas Rivron, a developmental biologist at the Institute of Molecular Biotechnology of the Austrian Academy of Sciences in Vienna. In a perspective published Thursday in Cell, he and an international group of leading luminaries in the fast-moving field of synthetic embryology — or “stembryology,” as it’s sometimes called — argue that these latest scientific advances justify a new definition for the human embryo that’s rooted not in how it was made, but in what it can become.

“Because of this new path, we think it becomes more and more important to think about the embryo not in terms of how it was formed but about the potential it has to generate something,” Rivron told STAT.

He and his co-authors proposed that embryos be defined as “a group of human cells supported by elements fulfilling extra-embryonic and uterine functions that, combined, have the potential to form a fetus.”

DALLAS – As the world continues to adapt to the growing trend of Artificial Intelligence (AI), South Korean scientists have unveiled a humanoid robot capable of piloting an aircraft.

Named Pibot, the life-sized robot, measuring 160 cm tall and weighing in at 65 kg, is capable of gripping the controls, memorizing aircraft manuals, and even responding to emergency situations. It is fitted with multiple cameras capable of monitoring the aircraft’s systems and operational conditions.

Currently under development by the Korea Advanced Institute of Science & Technology (KAIST), researchers utilized AI chatbots such as ChatGPT to create ways for PiBot to learn the pilot manuals for various aircraft. The robot can then be changed onto an alternative airframe by clicking the type. It can also memorize worldwide Jeppesen aeronautical navigation charts, an impossible task for its human equivalent.

The danger posed by conversational AI isn’t that it can say weird or dark things; it’s that it can manipulate you without your knowledge.