Year 2022 face_with_colon_three

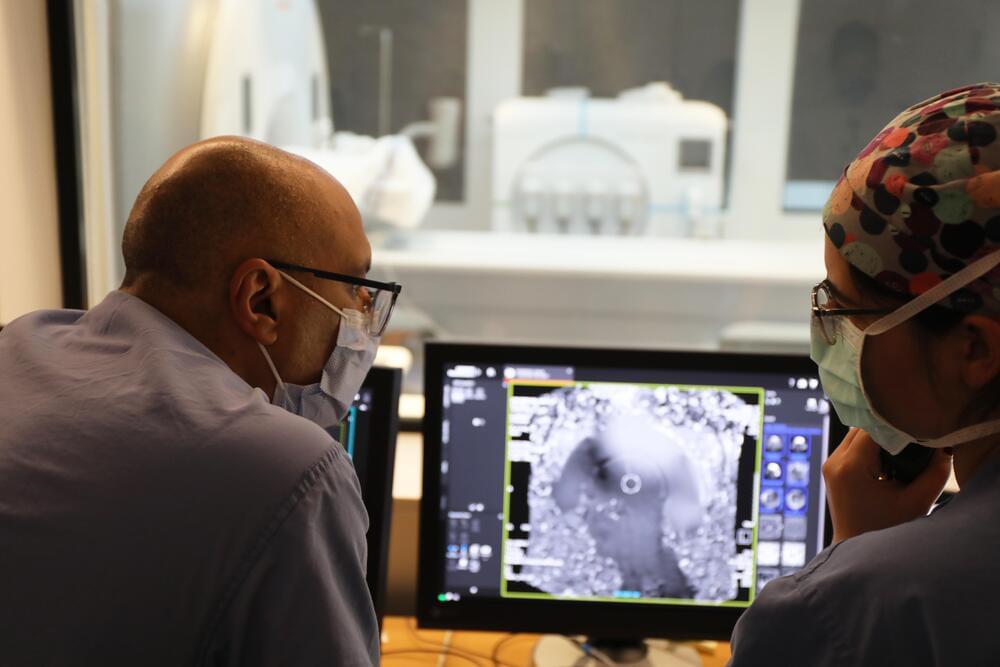

OHSU becomes the first in Oregon to offer focused ultrasound to immediately relieve symptoms of essential tremor, tremor-dominant Parkinson’s disease.

The key to understanding our universe lies in two theories—one of the generally-very-big and one of the generally-very-small. Albert Einstein’s Theory of General Relativity explains things like gravity and time, while Quantum Field Theory explores the subatomic world. However, one celestial object frustrates astrophysicists and quantum theorists in equal measure: black holes.

Because black holes release Hawking radiation (named for famous physicist Stephen Hawking), they eventually evaporate, which seemingly destroys the information that fell into the black hole. However, quantum field theory states that information cannot be destroyed. Result? Paradox.

One approach to AI uses a process called machine learning. In machine learning, a computer model is built to predict what may happen in the real world. The model is taught to analyze and recognize patterns in a data set. This training enables the model to then make predictions about new data. Some AI programs can also teach themselves to ask new questions and make novel connections between pieces of information.

“Computer models and humans can really work well together to improve human health,” explains Dr. Grace C.Y. Peng, an NIH expert on AI in medicine. “Computers are very good at doing calculations at a large scale, but they don’t have the intuitive capability that we have. They’re powerful, but how helpful they’re going to be lies in our hands.”

Researchers are exploring ways to harness the power of AI to improve health care. These include assisting with diagnosing and treating medical conditions and delivering care.

Part 3: This is the last of a three-part series on how Stanford Medicine researchers are designing vaccines that protect people from not merely individual viral strains but broad ranges of them. The ultimate goal: a vaccine with coverage so broad it can protect against viruses never before encountered.

Until now, vaccine efforts have mainly focused on stimulating B cells, described and discussed in Part 1 and Part 2. These antibody-producing immune cells’ virtue of being highly specific in what they target is also a vice. An antibody against influenza is unlikely to ever bind to, say, a coronavirus or a rabies virus.

Even when a virus mutates in some small way that distorts or disguises one of its biochemical bull’s-eyes, antibodies that worked before (because they aimed at that particular bull’s-eye) are now unemployed.

As we turn our attention from the front of the eye to the back, we also look to the future. Many studies have combined oculomics with AI tools to predict biological age from retinal biomarkers, such as retinal vasculature [1, 6], and even linked this to chronic disease risk, such as cardiovascular disease and cancer [7]. High resolution imaging tools also enable direct visualisation of the neural layers within the retina, which can show signs of neurodegenerative diseases, such as Alzheimer’s disease [1, 6], Parkinson’s disease [8], multiple sclerosis [6, 9], and even rare conditions, such as Lafora disease [10]. In many cases, the oculomic signs are present before symptoms arise. For example, it has been shown that proteins related to Alzheimer’s disease (such as amyloid-beta) accumulate at least one decade prior to cognitive decline [11] and these proteins also accumulate in the retina [12]. This is particularly pertinent to clinical research and drug development, as it enables identification of those who may benefit from intervention before irreversible damage has taken place.

Advances in imaging technology mean that we can now detect biomarkers at cellular resolution. We are continually finding new applications for imaging techniques to detect disease before it takes hold, providing the opportunity to intervene and potentially avoid disease altogether. It’s definitely an exciting time for oculomics research!

Crystallomancy has come a long way since Ancient Roman times, and it makes one wonder whether the scryers of the past could have predicted the transformation of orb-gazing from a mystical art to a rigorous science. Not only does Oculomics enable us to look into your past and present, but also has the potential to look into your future, providing you the opportunity to change your “fate”. Although we cannot be sure what form the advancements in imaging and AI tools will take over the coming years, we can be sure of one thing – that oculomics has a promising future in the quest for longevity.

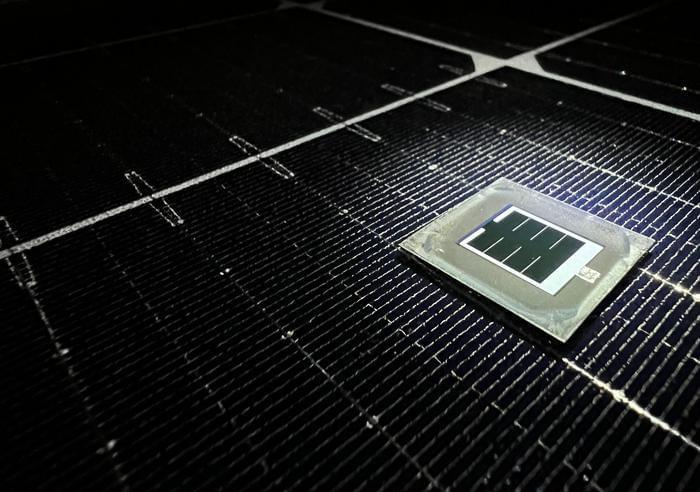

The market for perovskite/silicon tandems is expected to exceed $10 billion within a decade,” said Dr. Stefaan De Wolf. “KAUST is at the forefront of this revolution, laying the groundwork for affordable, accessible clean energy for all.

The road towards a cleaner future has taken a massive step forward, as a team of researchers from the King Abdullah University of Science and Technology (KAUST) have successfully conducted laboratory tests of perovskite/silicon tandem solar cells, which offer greater efficiency than crystalline silicon solar cells, which have long been the standard for solar energy technology. This study, which was published today in Science, was conducted at the KAUST Solar Center and holds the potential to design and develop more efficient solar cells for both Saudi Arabia and the entire world.

While the study outlines the incredible advances in laboratory tests with perovskite/silicon tandem solar cells, most notably a 33 percent increase in power efficiency compared to other joint solar cells, the researchers emphasize that many steps must be accomplished before this technology can achieve real-world applications, like commercialization. While they note that challenges for scaling up the technology could only be a few years away, the cost is the primary challenge for the foreseeable future.

The Inevitable Shift towards Machine Labor.

Impact Multiplier of Artificial Cognition and Synthetic Minds.

Economic Benefits of Cognition and Embodied Services.

Addressing Displacement with UBI Funded with Cognitive Services Impact Multipliers.

Navigating the Future with AI, Robotics, and UBI

Introduction.

In the context of the inevitable shift from human labor to machines, particularly in the realm of cognitive and physical tasks, the introduction of advanced technologies like Tesla’s Optimus robot and the development of artificial cognition and synthetic minds carry profound implications.

The Inevitable Shift towards Machine Labor.

The transition from human to machine labor in both cognitive and physical domains is becoming increasingly unavoidable. Technologies like Tesla Optimus represent a significant leap in this direction.

A previously unidentified genetic mutation in a small protein provides significant protection against Parkinson’s disease and offers a new direction for exploring potential treatments, according to a new USC Leonard Davis School of Gerontology study.

The variant, located in a mitochondrial microprotein dubbed SHLP2, was found to be highly protective against Parkinson’s disease; individuals with this mutation are half as likely to develop the disease as those who do not carry it. The variant form of the protein is relatively rare and is found primarily in people of European descent.

The findings appear in the journal Molecular Psychiatry.