Specific patterns of electrical activity in the hippocampus may indicate whether someone is about to misremember an event.

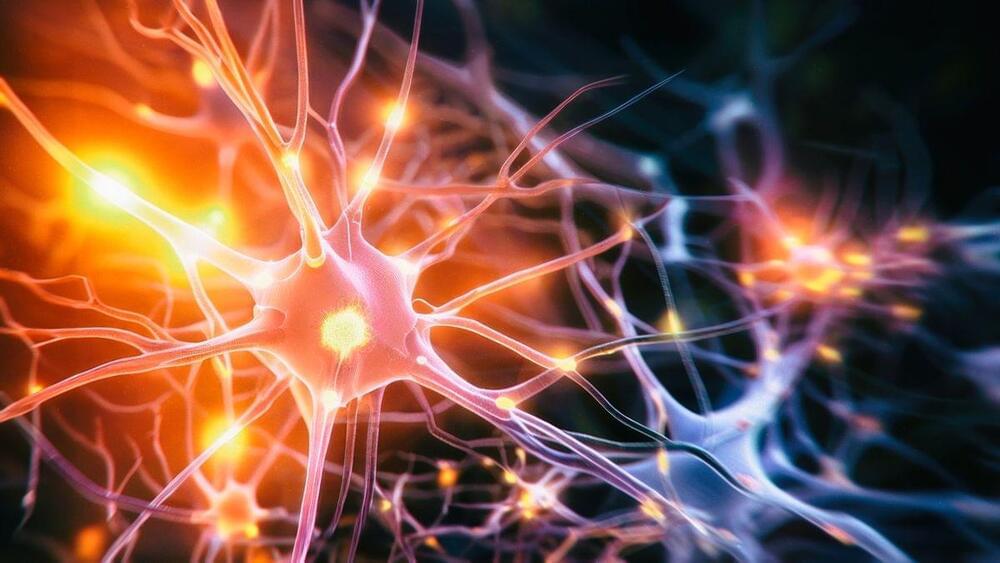

Researchers from Changchun University of Science and Technology (CUST) and City University of Hong Kong (CityU) have conducted a survey on the fabrication of flexible sensors using nanomaterials of different dimensions and the triggering methods of interaction between these sensors and virtual reality applications.

The review, published in the International Journal of Extreme Manufacturing (IJEM), highlights the recent advancements in nanomaterial-based flexible sensors (NMFSs) involving various nanomaterial frameworks such as nanoparticles, nanowires, and nanofilms.

Different triggering mechanisms for interaction between NMFSs and metaverse/virtual reality applications are discussed, e.g., skin-mechanics-triggered, temperature-triggered, magnetically triggered, and neural-triggered interfaces.

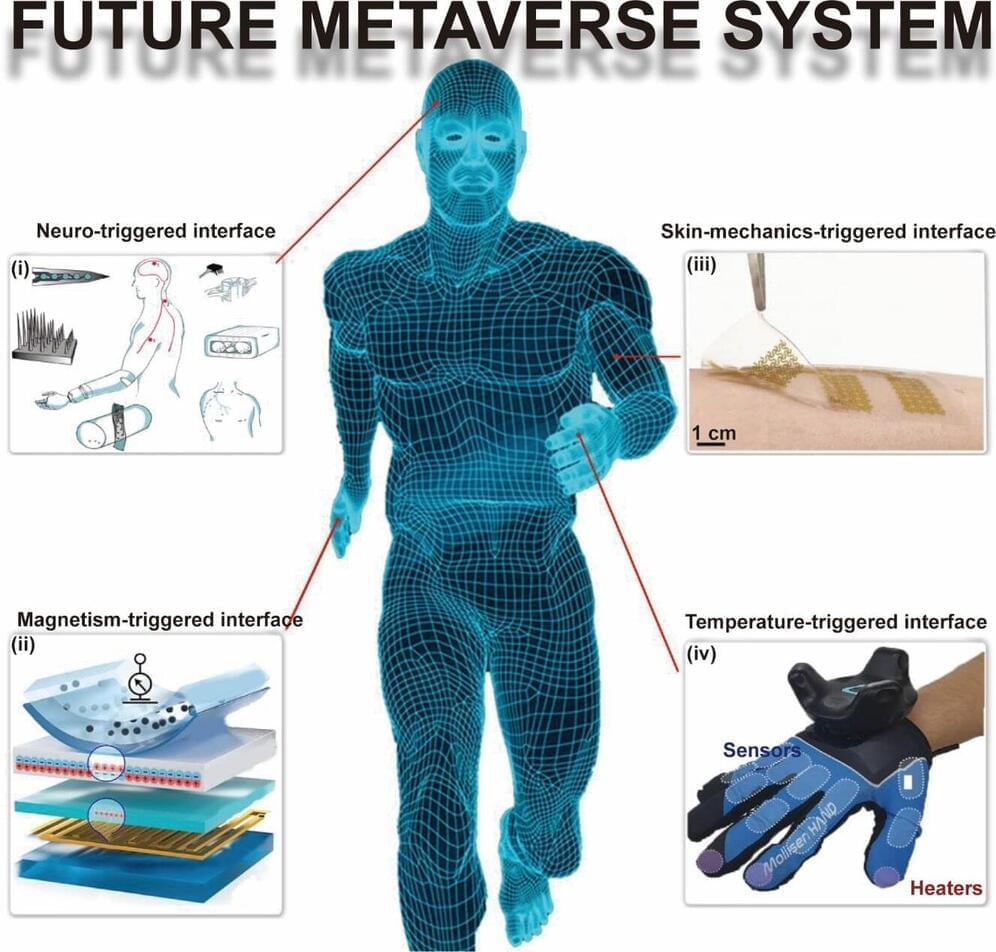

📢 Security Advisory : Two major security flaws in the Curl data transfer library exposed. CVE-2023–38545, the worst of them, could lead to code execution.

Learn more about them here: https://thehackernews.com/2023/10/two-high-risk-security-flaws-discovered.html.

Patch your systems and software immediately.

After his traumatic spinal cord injury in 2010, Drew Clayborn was motivated by the question, “How do I get back to doing life?” Since then, Clayborn finished high school, graduated college and started a nonprofit dedicated to providing resources and guidance to individuals and families affected by spinal cord injury. Resilience, exemplified by Drew, is a key factor to flourishing after spinal cord injury, according to recent Michigan Medicine research.

To learn more about Drew’s story and resilience research, visit: https://healthblog.uofmhealth.org/brain-health/my-life-matte…ord-injury.

Follow michigan medicine on social media:

Twitter: https://twitter.com/umichmedicine.

Instagram: https://www.instagram.com/umichmedicine/

Facebook: https://www.facebook.com/MichiganMedicine/

#Resilience #PatientStories #UniversityOfMichiganHealth

⚡ Beware of the HTTP/2 Rapid Reset attack!

A novel zero-day flaw is being exploited to launch record-breaking distributed #DDoS attacks.

Find out more here: https://thehackernews.com/2023/10/http2-rapid-reset-zero-day.html.

Learn how AWS, Cloudflare, and Google are addressing CVE-2023–44487.

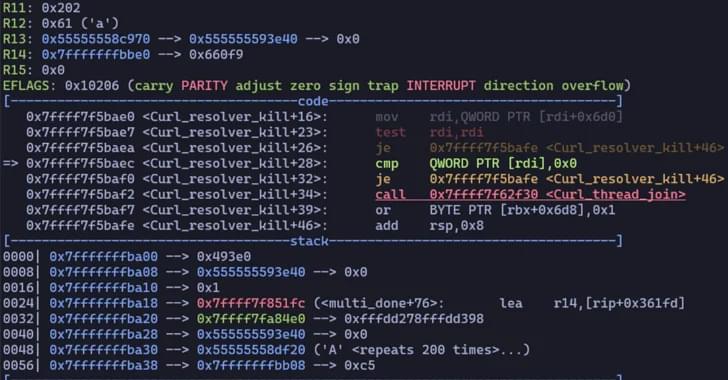

Amnesty International’s Predator Files investigation traces the widespread abuse of spyware by some nations against their own citizens. The ops are “industrial scale.” @jaivijayan explains:

The Intellexa alliance has been using a range of tools for intercepting and subverting mobile and Wi-Fi technologies to deploy its surveillance tools, according to an investigation by Amnesty International and others.

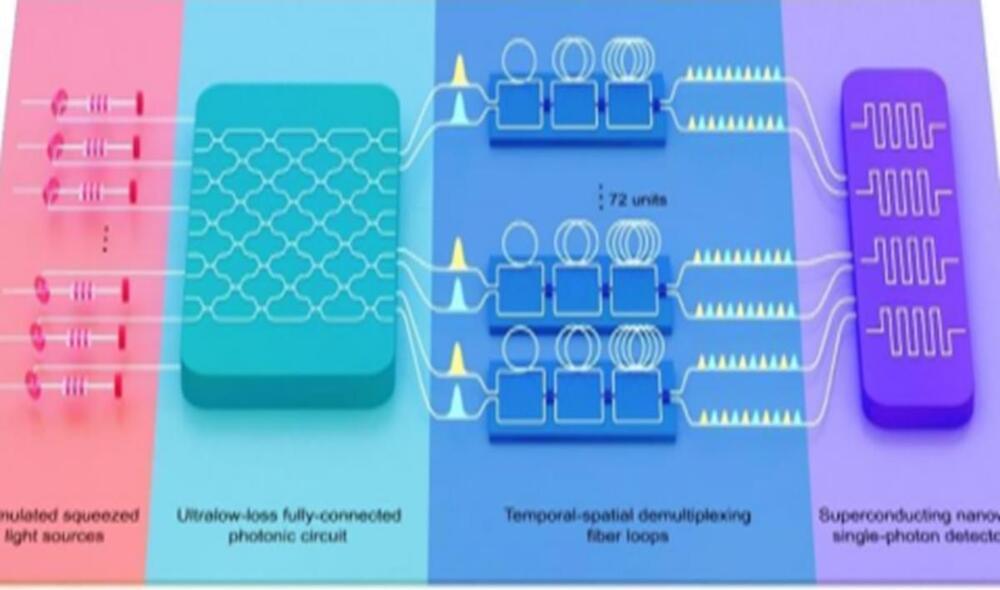

With the successful development of the Jiuzhang 3.0 quantum computer prototype, which makes use of 255 detected photons, China continues to hold a world-leading position in the field of quantum computer research and development, lead scientists for the program told the Global Times on Wednesday.

The research team, composed of renowned quantum physicists Pan Jianwei and Lu Chaoyang from the University of Science and Technology of China in collaboration with the Shanghai Institute of Microsystem and Information Technology under the Chinese Academy of Sciences and the National Parallel Computer Engineering Technology Research Center, announced the successful construction of a 255-photon-based prototype quantum computer named Jiuzhang 3.0 early Wednesday morning.

The quantum computing feat accomplished by the team of talents achieves a speed that is 10 quadrillion times faster in solving Gaussian boson sampling (GBS) problems compared with the world’s fastest supercomputers.