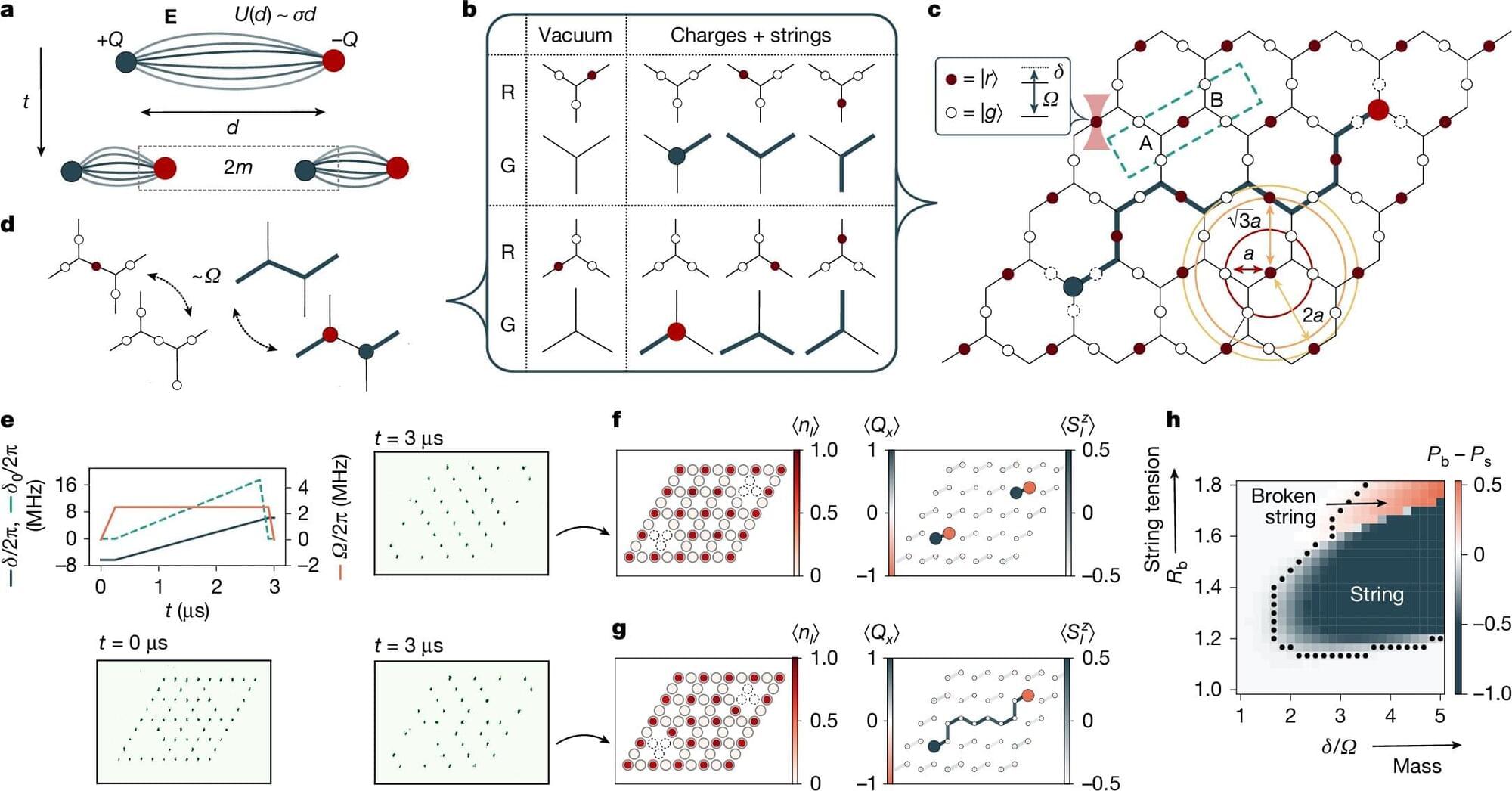

An international research collaboration featuring scientists from the FAMU-FSU College of Engineering and the National High Magnetic Field Laboratory has discovered a fundamental universal principle that governs how microscopic whirlpools interact, collide and transform within quantum fluids, which also has implications for understanding fluids that behave according to classical physics.

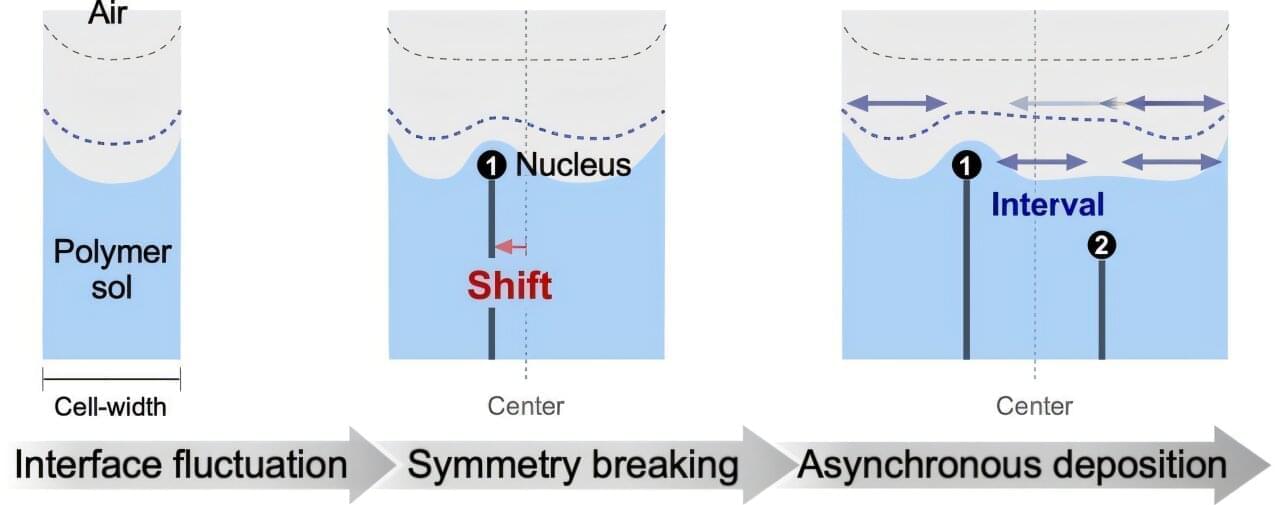

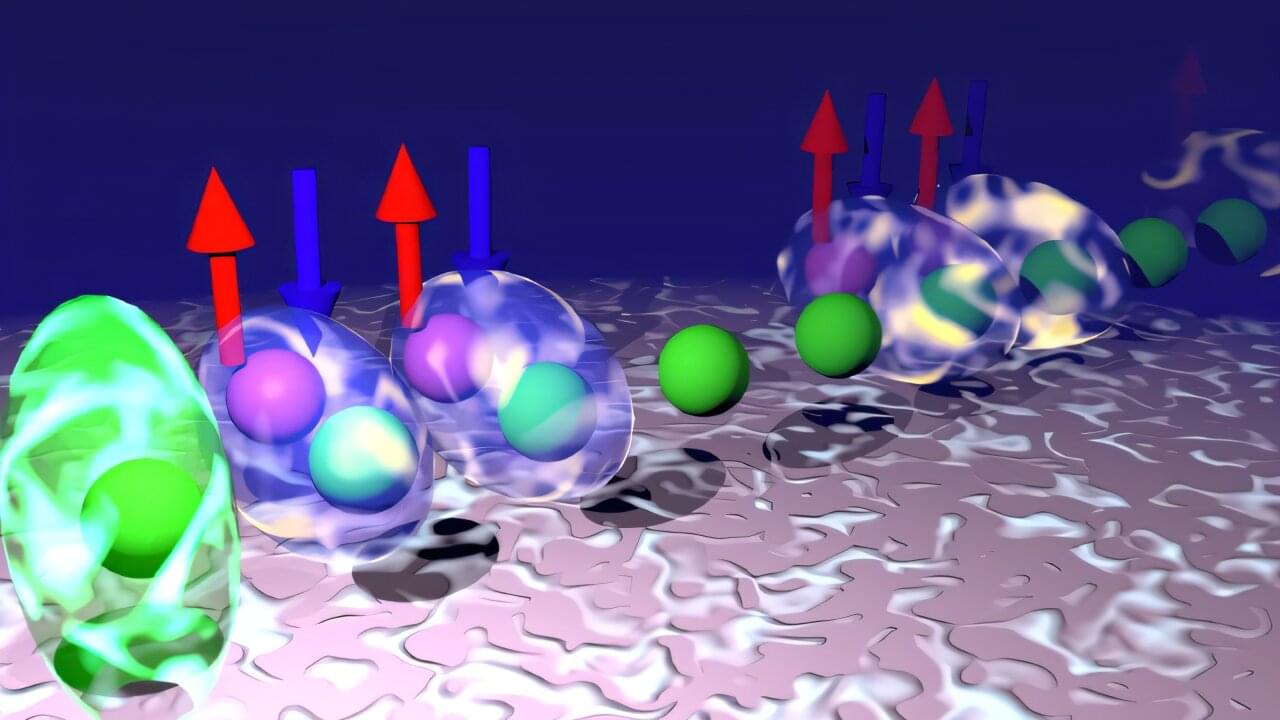

The study, which was published in the Proceedings of the National Academy of Sciences, revealed new insights into vortex dynamics within superfluid helium, a remarkable liquid that exhibits zero-resistance flow at temperatures approaching absolute zero. The research demonstrates that when these quantum vortices intersect and reconnect, they separate faster than their initial approach velocity, creating bursts of energy that characterize turbulence in both quantum and classical fluids.

“Superfluids offer a uniquely clear perspective on turbulence,” said FAMU-FSU College of Engineering Professor Wei Guo, a study co-author. “We’re beginning to understand the universal physics that connects quantum and classical worlds, and that’s an exciting frontier for both science and technology.”