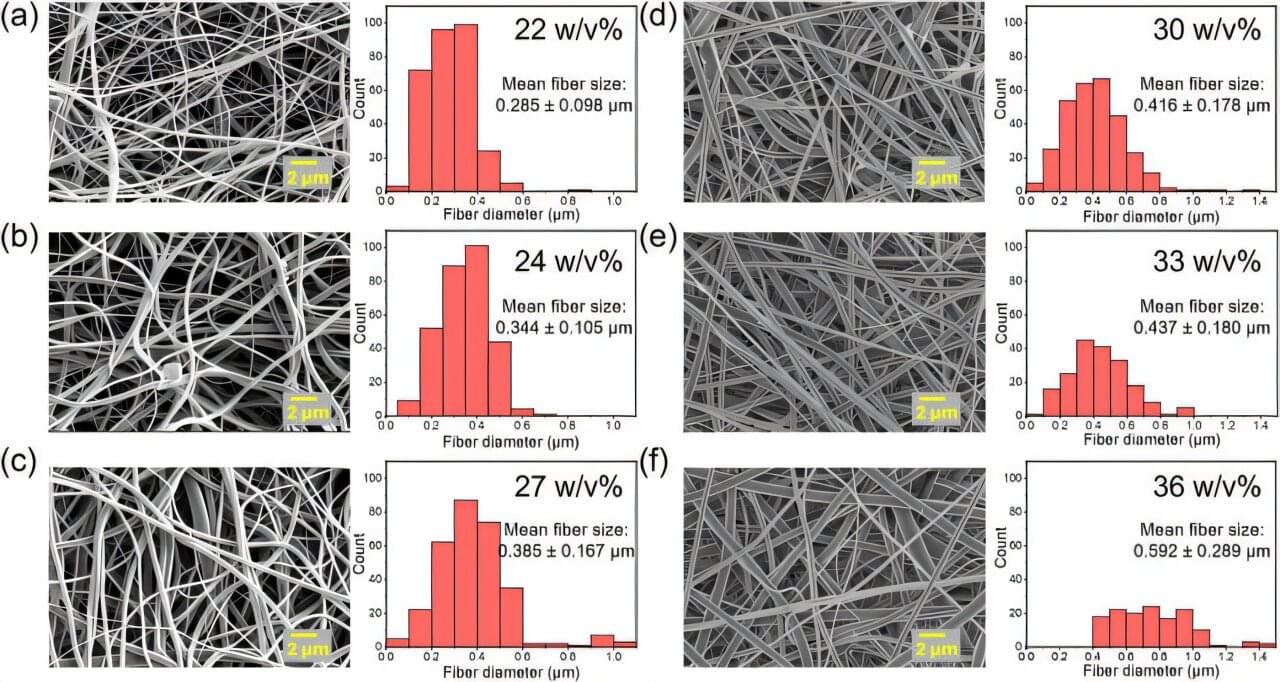

Could clothing monitor a person’s health in real time, because the clothing itself would be a self-powered sensor? A new material created through electrospinning, which is a process that draws out fibers using electricity, brings this possibility one step closer.

A team led by researchers at Penn State has developed a new fabrication approach that optimizes the internal structure of electrospun fibers to improve their performance in electronic applications. The team has published its findings in the Journal of Applied Physics.

This novel electrospinning approach could open the door to more efficient, flexible and scalable electronics for wearable sensors, health monitoring and sustainable energy harvesting, according to Guanchun Rui, a visiting postdoctoral student in the Department of Electrical Engineering and the Materials Research Institute and co-lead author of the study.