Two-dimensional (2D) semiconductors, materials that can conduct electricity and are only a few atoms thick, are promising alternatives to the conventional silicon-based semiconductors currently used to fabricate many electronics. Despite their promise, these materials have not yet been deployed on a large scale.

One reason for this is that reliably synthesizing them and patterning them to produce wafers (i.e., circular substrates employed in the manufacturing of electronics) has so far proved challenging. In fact, many existing patterning techniques rely on chemical processes or polymer masks, both of which can leave unwanted residues on a wafer or damage the surface of 2D semiconductors.

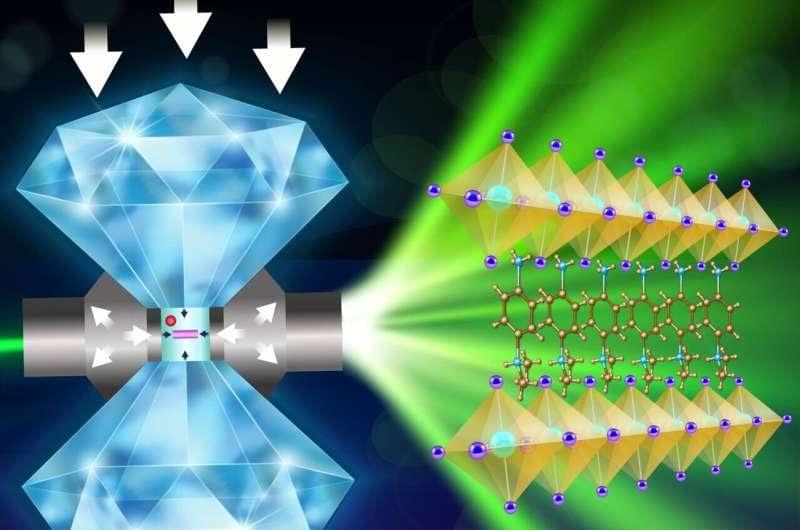

Researchers at Nanyang Technological University recently developed a new strategy to pattern 2D films into high-quality wafer-scale arrays, without damaging them or introducing undesirable residues. Their proposed method, outlined in a paper published in Nature Electronics, entails the use of a metal stamp producing three-dimensional (3D) patterns, which can be pressed onto 2D materials to produce a wafer with desired patterns.