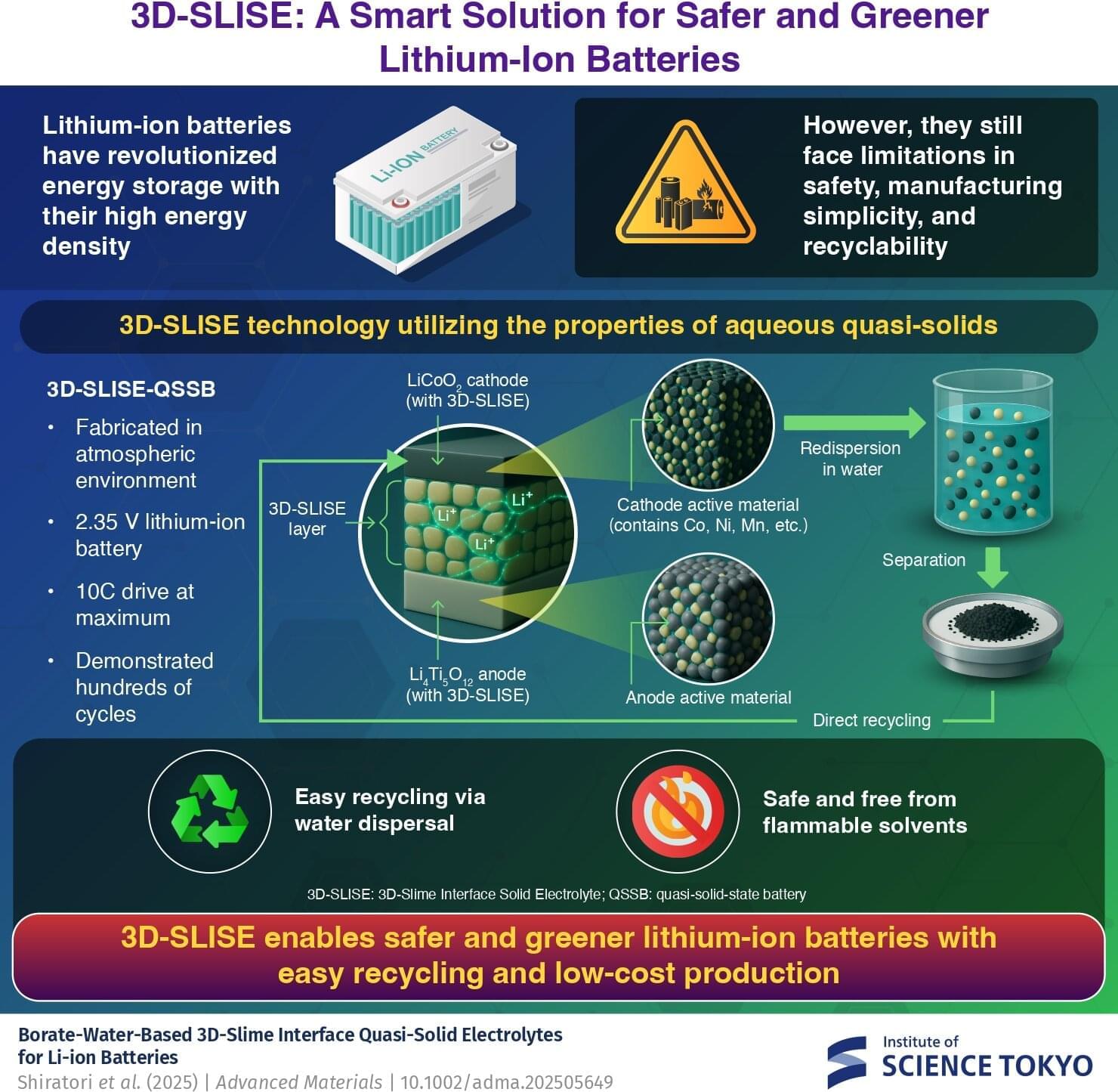

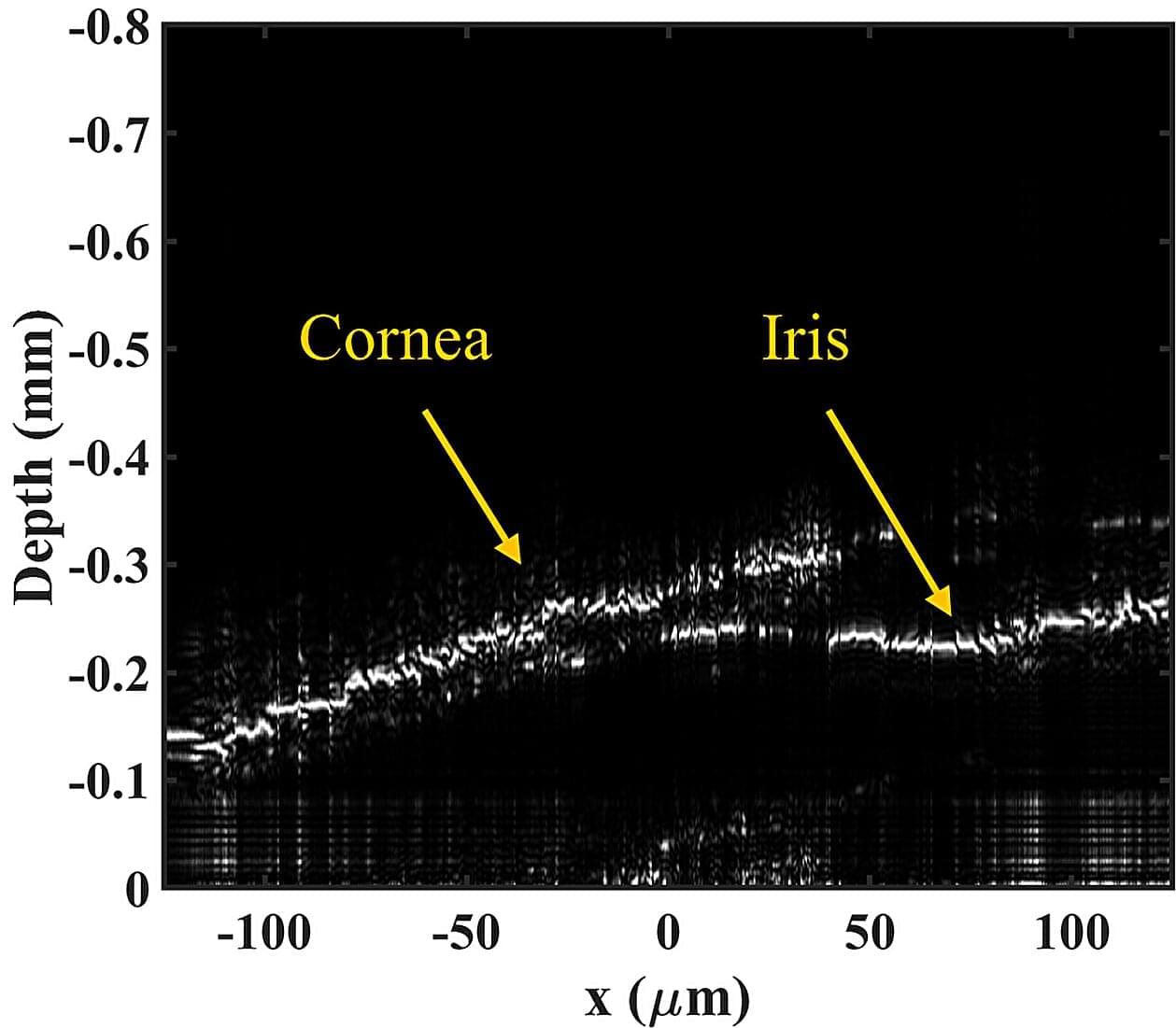

3D-SLISE is a quasi-solid electrolyte developed at the Institute of Science Tokyo, which enables safe, fast-charging/discharging of 2.35 V lithium-ion batteries to be fabricated under ambient conditions. With energy-efficient manufacturing using raw materials free from flammable organic solvents, the technique eliminates the need for dry rooms or high-temperature processing. Moreover, it also allows direct recovery of active materials through water dispersal—ensuring a sustainable, recyclable approach to battery production.

In today’s era of portable power and clean energy, lithium-ion batteries form the backbone of modern technology—powering everything from smartphones to electric vehicles. While demand for lithium-ion batteries continues to grow, so do concerns about their safety, environmental impact, and recyclability. Most lithium-ion batteries that rely on flammable organic solvents are energy-intensive to manufacture, and require complicated recycling processes. These issues not only drive up costs but also pose serious safety and environmental risks —highlighting the need for safer and cleaner alternatives.

To address this challenge, a research team from Institute of Science Tokyo (Science Tokyo), Japan, led by Specially Appointed Professor Yosuke Shiratori and Associate Professor Shintaro Yasui from the Zero-Carbon Energy Research Institute, Science Tokyo, developed a new quasi-solid electrolyte called 3D-Slime Interface Quasi-Solid Electrolyte (3D-SLISE), which can transform battery manufacturing. With a simple borate-water matrix, the electrolyte supports the production of 2.35 V lithium-ion batteries under standard air conditions. The detailed findings of the study were made available in the journal Advanced Materials on July 9, 2025.