Moltex’s WATSS technology transforms nuclear waste into a valuable energy resource, offering a cost-effective solution for the industry.

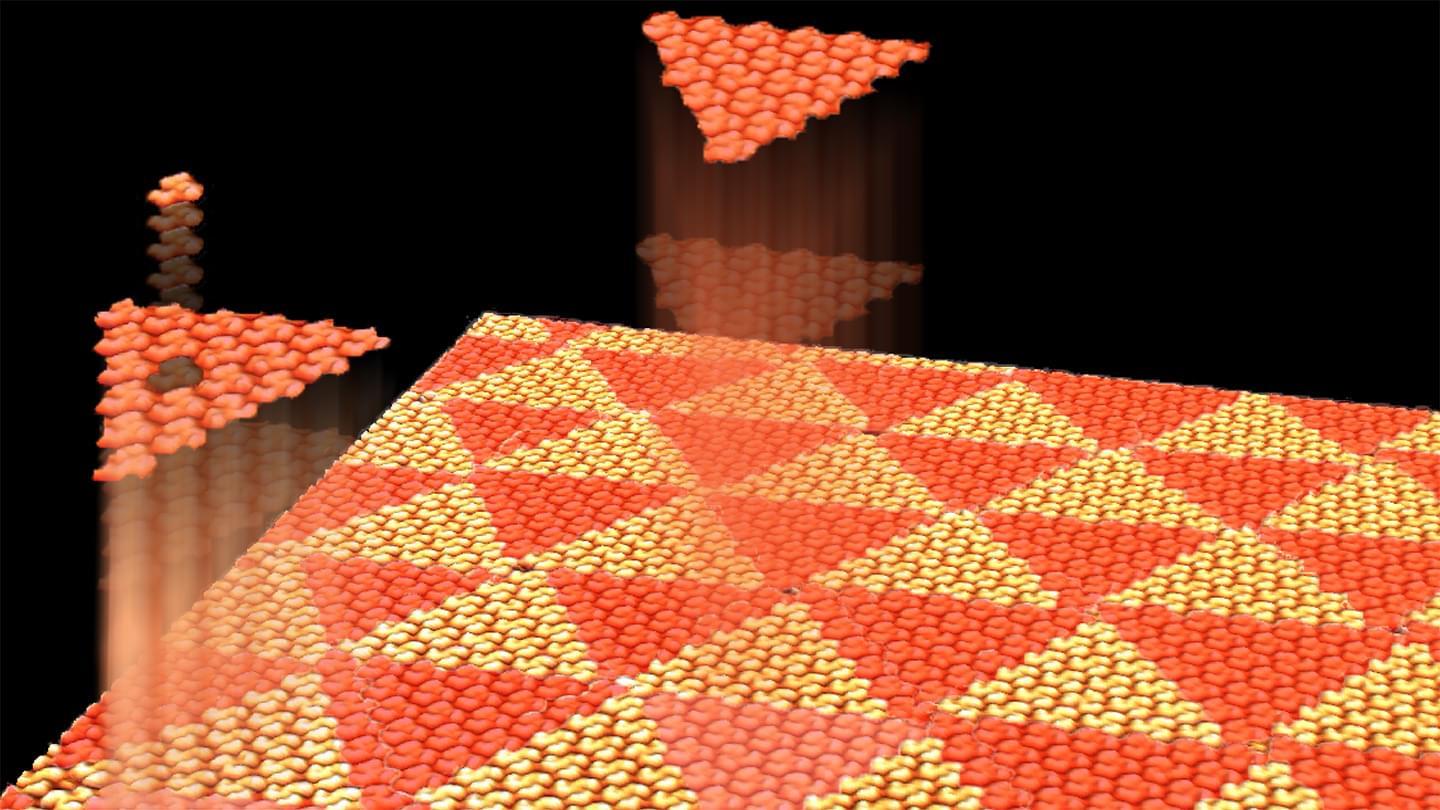

A collaboration of researchers in Austria and China has built a universal inverse-design magnonic device that can efficiently produce new electronic components based solely on a definition of the desired performance, and do the job in minutes or hours. They published the result in Nature Electronics.

Designing an electronic component usually requires extensive manual design and simulation to achieve a desired functionality. Inverse design eliminates these steps. It is a two-step process: First, the developers divide a design area into an array of smaller, programmable elements. Then, they deploy iterative feedback-loop optimization to tune these elements to achieve a predefined functionality.

This new device manipulates magnons, the quasiparticle quanta of magnetic spin waves. There have been magnonic devices and inverse-design devices, but this is the first universal magnonic inverse design device. Hypothetically, this kind of device can duplicate the performance of anything from a diode to a neuromorphic circuit.

In IDB, macrophages, a type of immune cell begins producing excessive levels of pro-inflammatory cytokines. These proteins then stick to macrophage receptors which triggers them to produce even more of this inflammatory protein. But UC San Diego researchers can break that cycle with a microrobot.

In previous experiments, UC San Diego researchers delivered drugs with microrobots, most notably in the lungs, and succeeded in minimizing the drug’s side effects. For the IBD study, however, they didn’t even need to use a drug.

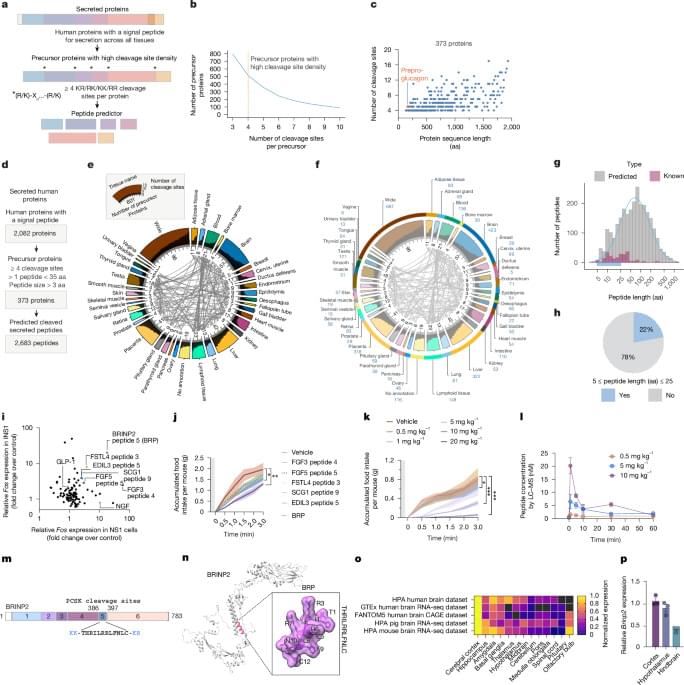

Computational drug discovery is used to identify a 12-mer peptide derived from BRINP2 with potent anti-obesity effects that are independent of leptin, glucagon-like peptide 1 receptor and melanocortin 4 receptor.

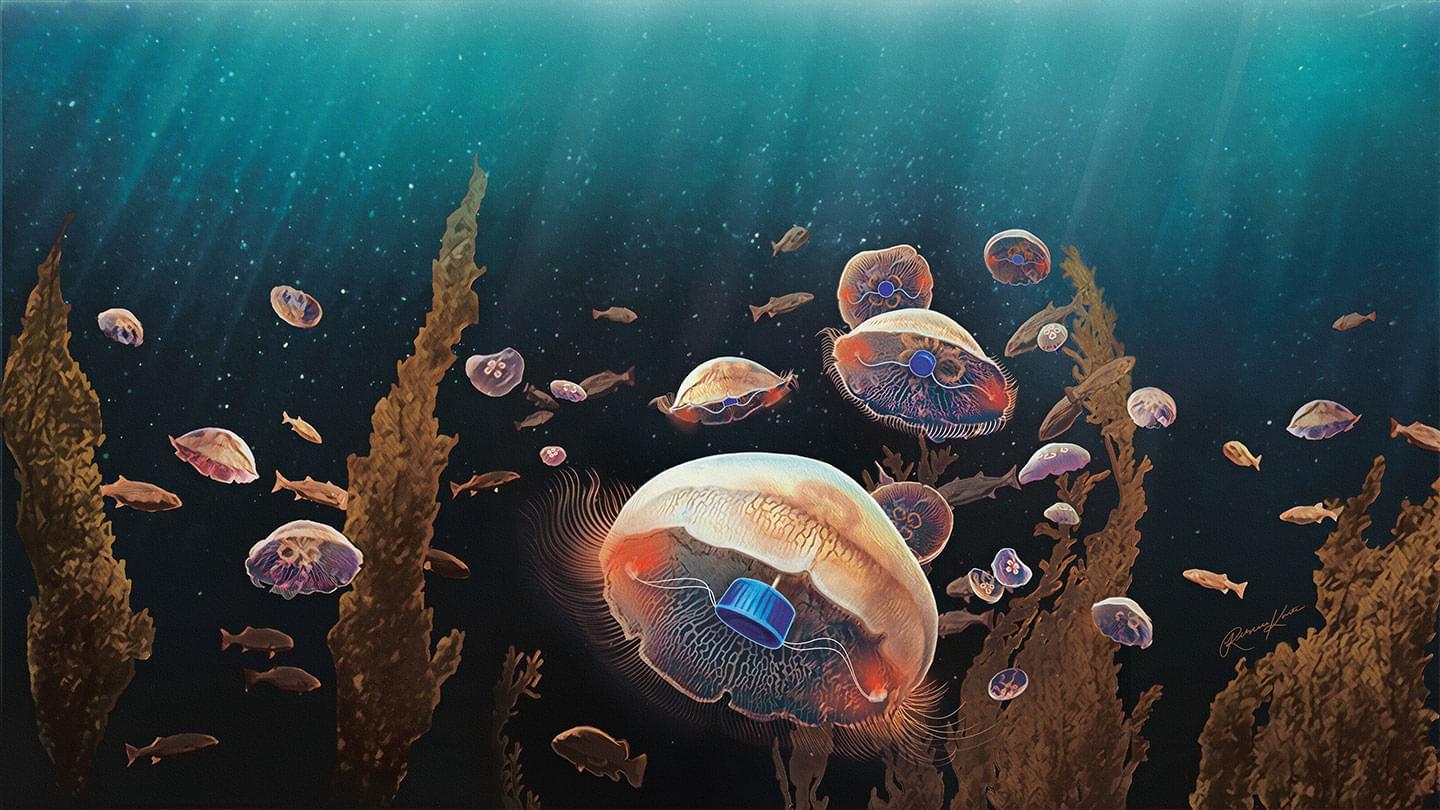

Using body parts from simple animals in robotics is not as controversial. But it’s still important to consider the impact on these living creatures. It may seem that bugs and jellyfish and mollusks aren’t capable of caring about how we use their bodies. But what if we’re wrong about that? Some researchers are finding that such creatures might have more awareness and feelings than expected.

Living robots also interact with the environment. What if a jellyfish outfitted with electronics got eaten? Xu is hoping to develop biodegradable electronics that wouldn’t harm other animals or pollute the ocean.

Biohybrid robots blur the line between machine and living thing. The jellyfish cyborgs are obviously still alive. But most biohybrids don’t really fit into one category or the other. Shin says of her heart-cell-covered bot: “it’s not a creature.” But it’s not a typical robot, either.

Chemists identify a single molecule that naturally tiles in nonrepeating patterns, which could help build materials with novel electronic properties.

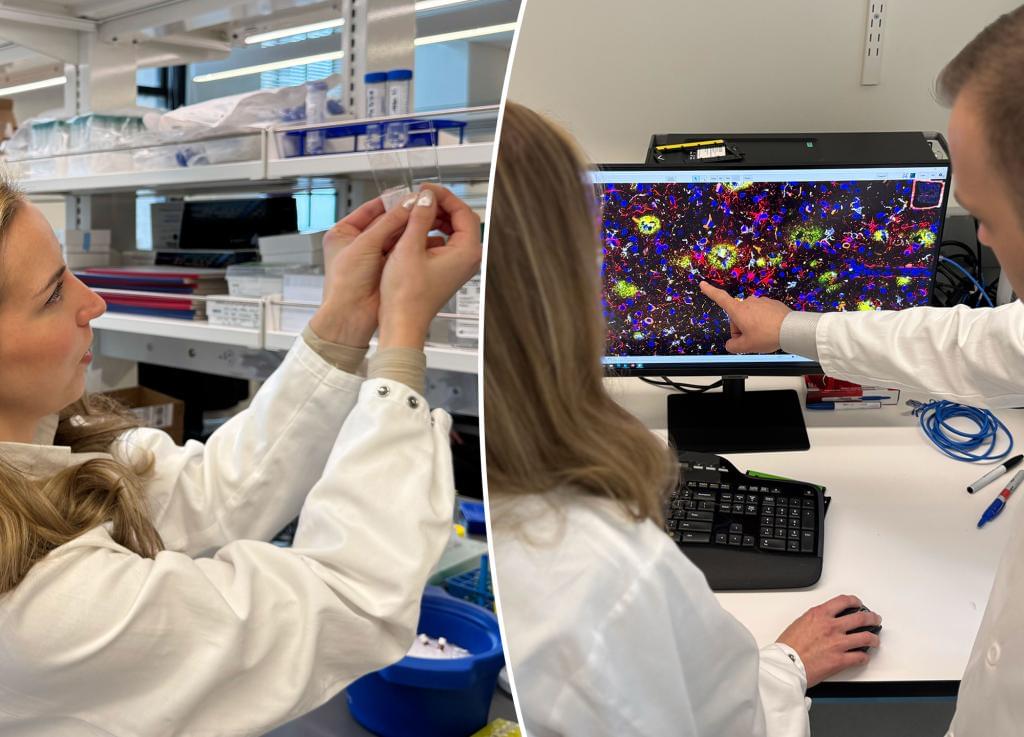

Scientists have long been racking their brains for ways to treat Alzheimer’s disease, the most common type of dementia.

Turns out that the answer may lie within our own brains. Researchers from Northwestern University suggest that enhancing the brain’s immune cells may better equip them to clear out harmful clumps of the toxic protein amyloid beta, a hallmark of Alzheimer’s.

“Our study is highly novel because we had the rare opportunity to analyze one of the largest post-mortem brain cohorts of Alzheimer’s patients treated with amyloid-targeting drugs — similar to those now approved by the FDA for Alzheimer’s disease,” lead author Lynn van Olst said.

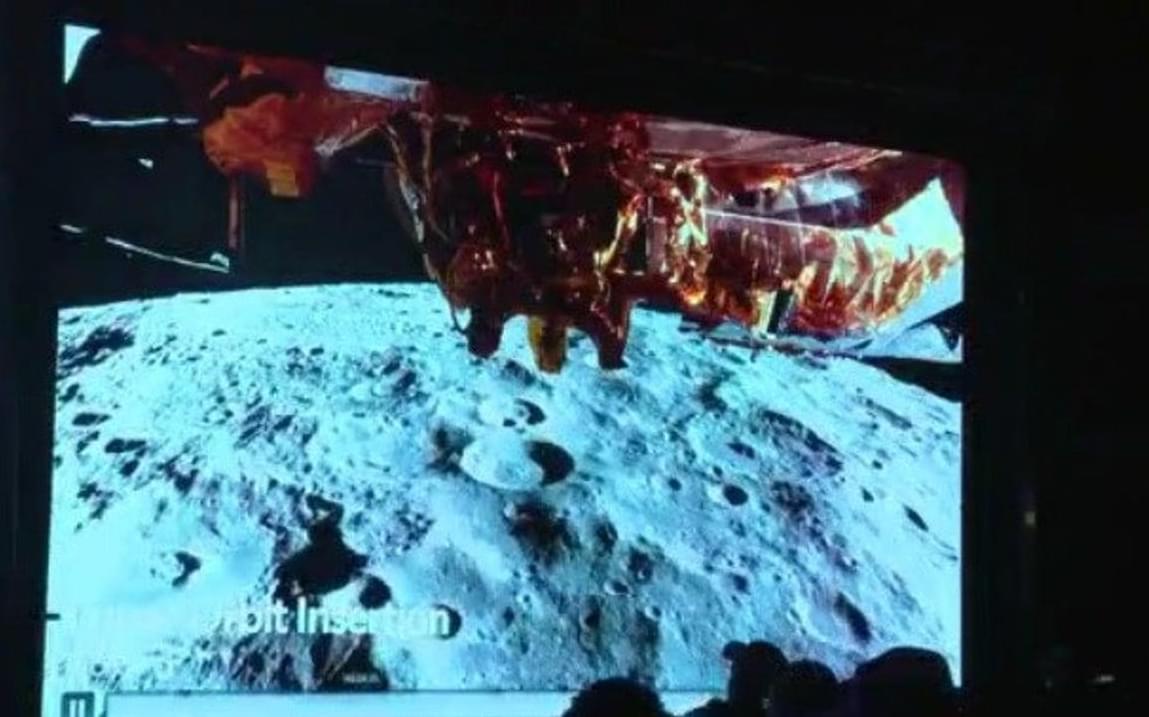

The successful landing of a Cedar Park lunar lander is putting the pressure on efforts to build a workforce capable of reaching for the stars.