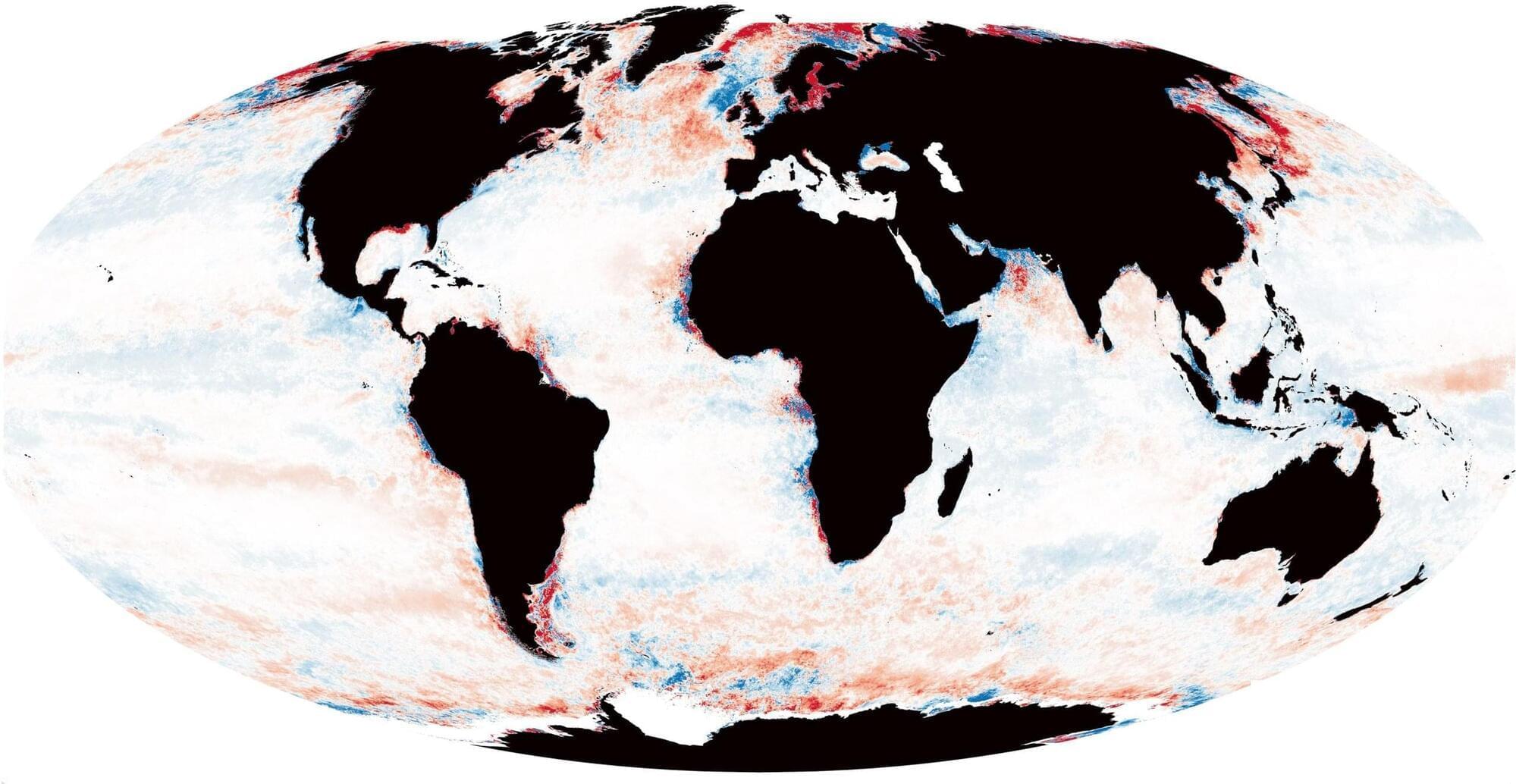

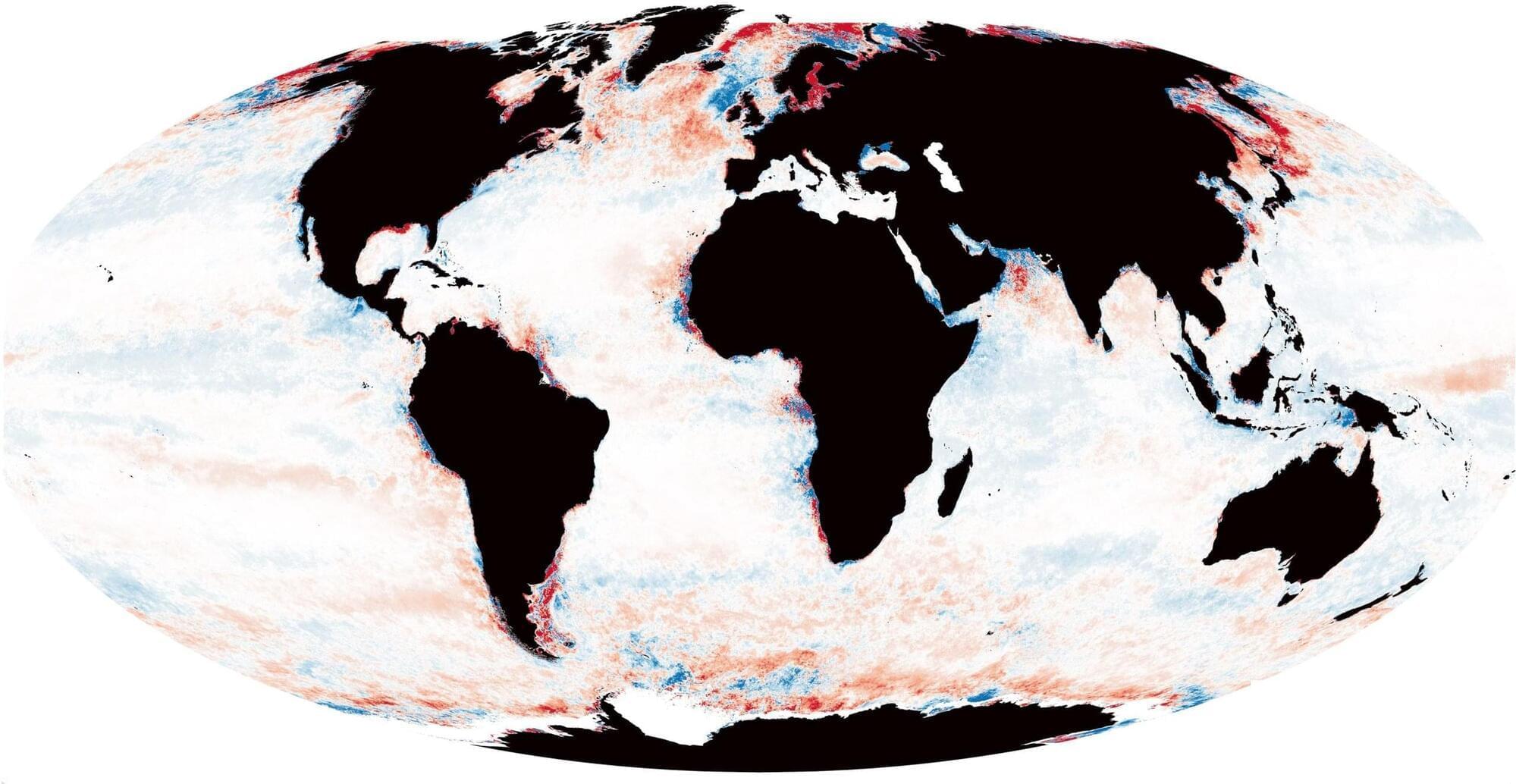

Ocean darkening is rapidly spreading, squeezing marine life closer to the surface and altering ecosystems worldwide. Satellite data shows the photic zone is shrinking fast.

While many associate account takeovers with personal services, the real threat is unfolding in the enterprise. Flare’s latest research, The Account and Session Takeover Economy, analyzed over 20 million stealer logs and tracked attacker activity across Telegram channels and dark web marketplaces. The findings expose how cybercriminals weaponize infected employee endpoints to hijack enterprise sessions—often in less than 24 hours.

Here’s the real timeline of a modern session hijacking attack.

Infection and Data Theft in Under an Hour.

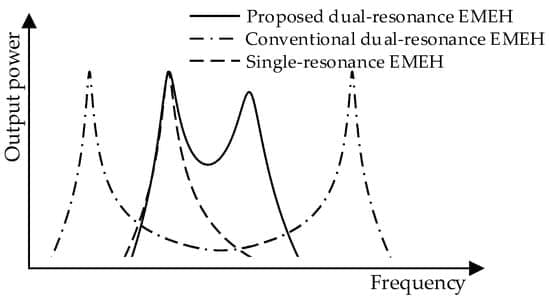

A dual resonance vibration electromagnetic energy harvester (EMEH) is proposed in this paper to extend frequency range. Compared with the conventional dual resonance harvester, the proposed system realizes an enhanced “band-pass” harvesting characteristic by increasing the relative displacement between magnet and coil among two resonance frequencies with a significant improvement in the average harvested power. Furthermore, two resonant frequencies are decoupled in the proposed system, which leads to a more straightforward design. The proposed dual resonance EMEH is constructed with a tubular dual spring-mass structure. It is designed with a serpentine planar spring and the coil position is optimized for higher power density with an overall size of 53.9 cm3 for the dual resonance EMEH. It realizes an output power of 11 mW at the first resonant frequency of 58 Hz, 14.9 mW at the second resonant frequency of 74.5 Hz, and 0.52 mW at 65 Hz, which is in the middle of the two resonance frequencies. The frequency range of output power above 0.5 mW is from 55.8 Hz to 79.1 Hz. The maximum normalized power density (NPD) reaches up to 2.77 mW/(cm3·g2). Compared with a single resonance harvester design under the same topology and outer dimension at a resonant frequency of 74.5 Hz, the frequency range in the proposed EMEH achieves more than a 2× times extension. The proposed dual resonance EMEH also has more than 2 times wider frequency range than other state-of-art wideband EMEHs. Therefore, the proposed dual resonance EMEH is demonstrated in this paper for a high maximum NPD and higher NPD over a wide frequency range.

A digital twin helped operators of a Dutch battery energy storage system detect a hidden 4 percent degradation.

Sounds like magic, works like physics.