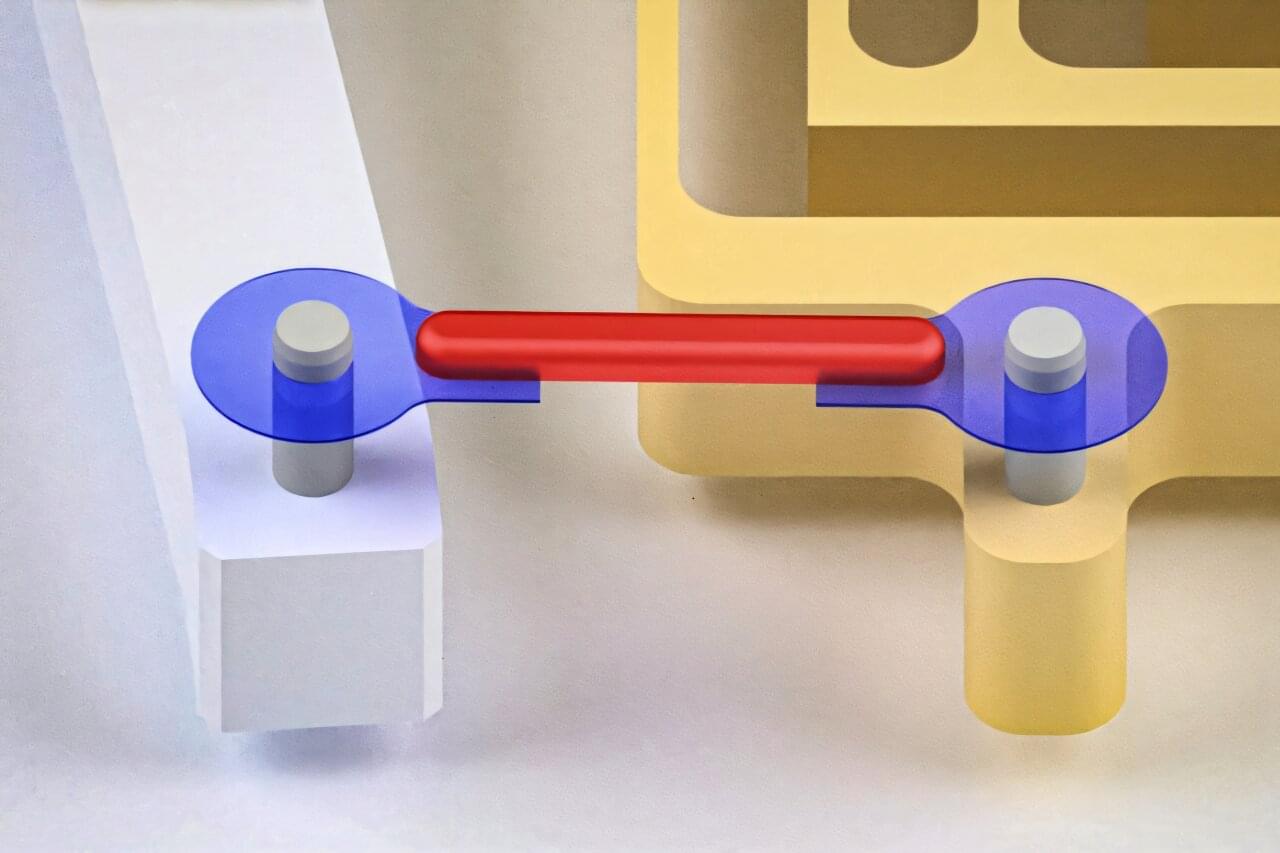

Over the past decades, many research teams worldwide have started working on electronic fibers. These are yarn-like components with electronic properties that can be weaved or assembled to create new innovative textile-based electronics, clothes or other wearable systems that can sense their surroundings, monitor specific physiological signals or perform other functions.

Electronic fibers typically contain both regions via which electric current can flow (i.e., conductive domains) and insulating regions that store electric charge (i.e., dielectric domains). Reliably arranging these domains into complex architectures to produce fibers with desired properties can be difficult and most previously introduced methods are difficult to implement on a large scale.

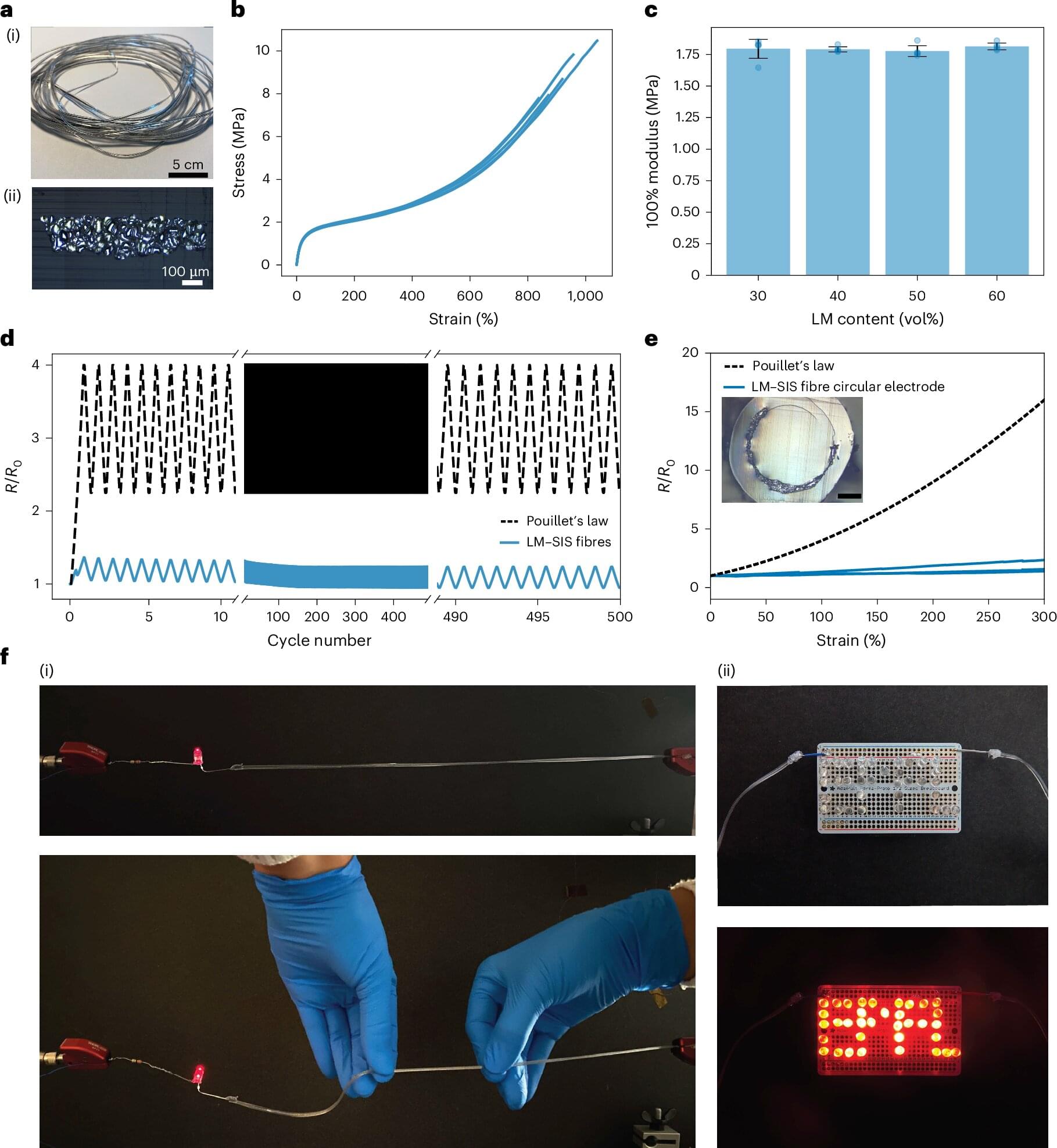

Researchers at École polytechnique fédérale de Lausanne recently demonstrated the potential of a scalable technique known as thermal drawing for creating highly performing, elastomer and liquid metal-based electronic fibers. This approach, outlined in a paper published in Nature Electronics, allowed them to create electronic fibers that were successfully used to fabricate a new textile-based capacitive strain sensor.