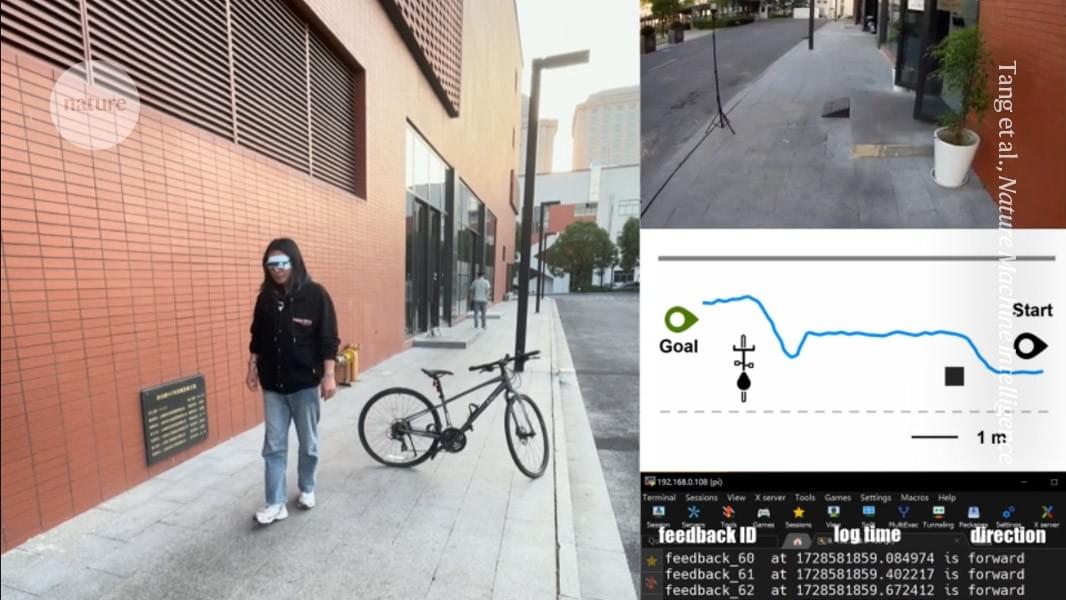

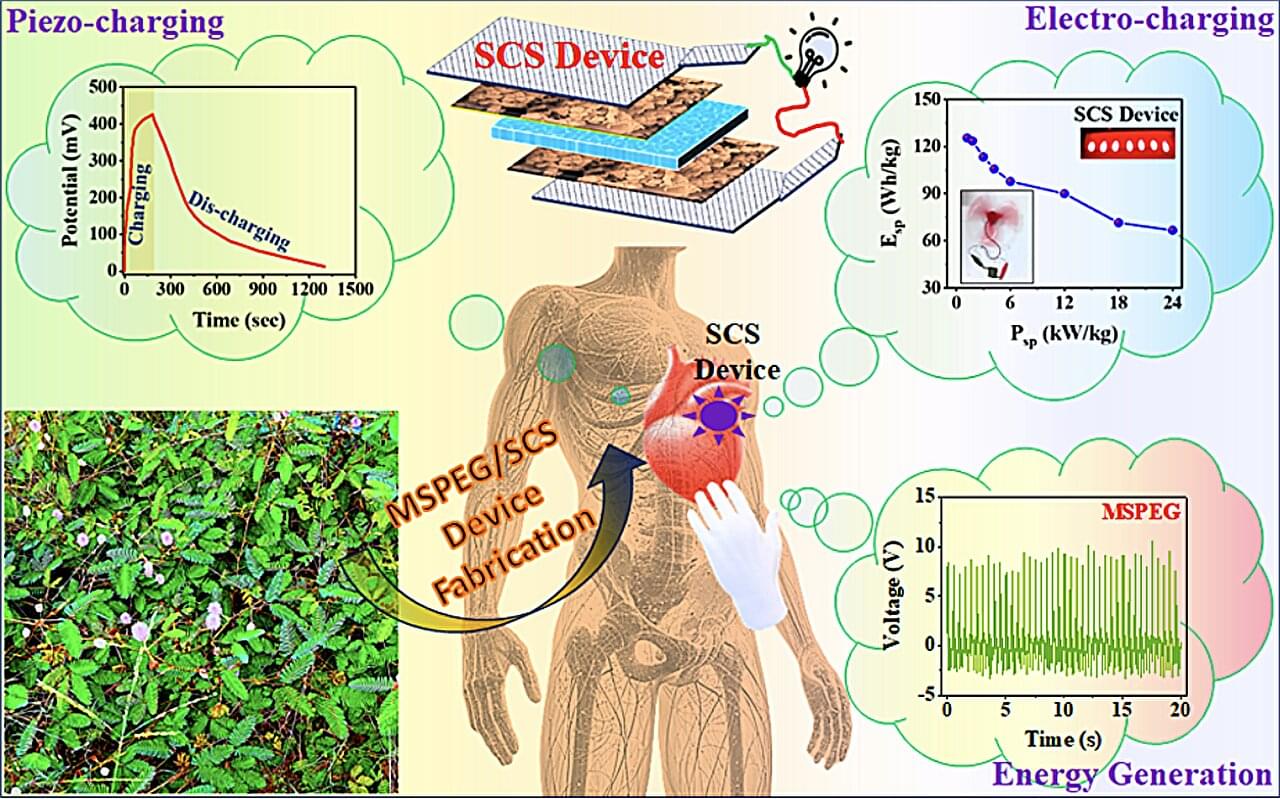

Human cyborgs are individuals who integrate advanced technology into their bodies, enhancing their physical or cognitive abilities. This fusion of man and machine blurs the line between science fiction and reality, raising questions about the future of humanity, ethics, and the limits of human potential. From bionic limbs to brain-computer interfaces, cyborg technology is rapidly evolving, pushing us closer to a world where humans and machines become one.

Shocking transformation, futuristic nightmare, beyond human limits, man merges with machine, terrifying reality, future is now, ultimate evolution, secret experiments exposed, technology gone too far, sci-fi turns real, mind-blowing upgrade, science fiction no more, unstoppable machine man, breaking human boundaries, dark future ahead, human cyborgs, cyborg technology, cyborg implants, cyborg augmentation, cyborg evolution, cyborg future, cyborg innovations, cyborg advancements, cyborg ethics, cyborg integration, cyborg society, cyborg culture, cyborg development, cyborg research, cyborg science, cyborg engineering, cyborg design, cyborg applications, cyborg trends, cyborg news, cyborg updates, cyborg breakthroughs, cyborg discoveries, cyborg implants, bionic limbs, neural interfaces, prosthetic enhancements, biohacking, cybernetics, exoskeletons, brain-computer interfaces, robotic prosthetics, augmented humans, wearable technology, artificial organs, human augmentation, smart prosthetics, neuroprosthetics, biomechatronics, implantable devices, synthetic biology, transhumanism, bioengineering, nanotechnology, genetic engineering, bioinformatics, artificial intelligence, machine learning, robotics, automation, virtual reality, augmented reality, mixed reality, haptic feedback, sensory augmentation, cognitive enhancement, biofeedback, neurofeedback, brain mapping, neural networks, deep learning, biotechnology, regenerative medicine, tissue engineering, stem cells, gene therapy, personalized medicine, precision medicine, biomedical engineering, medical devices, health tech, digital health, telemedicine, eHealth, mHealth, health informatics, wearable sensors, fitness trackers, smartwatches, health monitoring, remote monitoring, patient engagement, health apps, health data, electronic health records, health analytics, health AI, medical robotics, surgical robots, rehabilitation robotics, assistive technology, disability tech, inclusive design, universal design, accessibility, adaptive technology, human-machine interaction, human-computer interaction, user experience, user interface, UX design, UI design, interaction design, design thinking, product design, industrial design, innovation, technology trends, future tech, emerging technologies, disruptive technologies, tech startups, tech entrepreneurship, venture capital, startup ecosystem, tech innovation, research and development, R&D, scientific research, science and technology, STEM, engineering, applied sciences, interdisciplinary research, academic research, scholarly articles, peer-reviewed journals, conferences, symposiums, workshops, seminars, webinars, online courses, e-learning, MOOCs, professional development, continuing education, certifications, credentials, skills development, career advancement, job market, employment trends, workforce development, labor market, gig economy, freelancing, remote work, telecommuting, digital nomads, coworking spaces, collaboration tools, project management, productivity tools, time management, work-life balance, mental health, wellness, self-care, mindfulness, meditation, stress management, resilience, personal growth, self-improvement, life coaching, goal setting, motivation, inspiration, success stories, case studies, testimonials, reviews, ratings, recommendations, referrals, networking, professional associations, industry groups, online communities, forums, discussion boards, social media, content creation, blogging, vlogging, podcasting, video production, photography, graphic design, animation, illustration, creative arts, performing arts, visual arts, music, literature, film, television, entertainment, media, journalism, news, reporting, storytelling, narrative, communication, public speaking, presentations, persuasion, negotiation, leadership, management, entrepreneurship, business, marketing, advertising, branding, public relations, sales, customer service, client relations, customer experience, market research, consumer behavior, demographics, psychographics, target audience, niche markets, segmentation, positioning, differentiation, competitive analysis, SWOT analysis, strategic planning, business development, growth strategies, scalability, sustainability, corporate social responsibility, ethics, compliance, governance, risk management, crisis management, change management, organizational behavior, corporate culture, diversity and inclusion, team building, collaboration, innovation management, knowledge management, intellectual property, patents, trademarks, copyrights.