Toyota known for its hybrid innovation, has been cautious with fully electric vehicles (EVs), only launching its first EV, the bZ4X, in 2022.

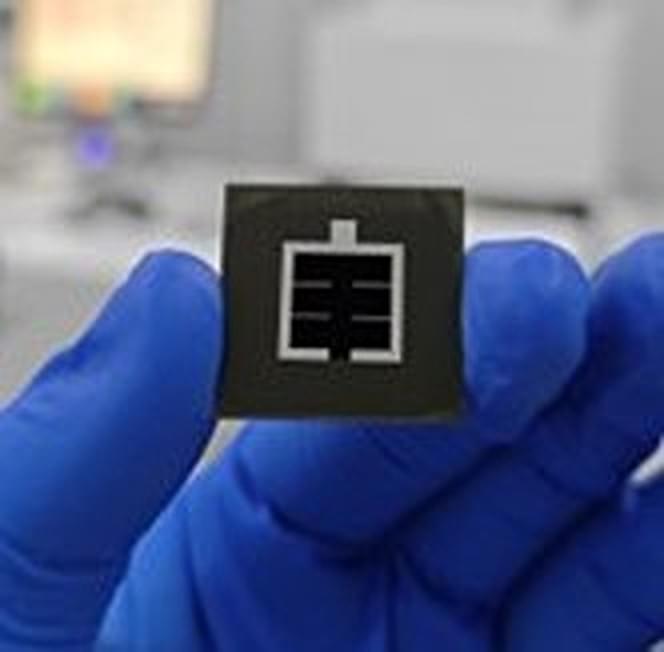

Solid-state batteries are smaller and more durable, making them well-suited to daily fast charging and capable of carrying additional weight, like extra passengers or cargo. This technology has been difficult to scale up, but Toyota’s strong financial base and reputation for reliability position it uniquely to introduce these advanced batteries to the mainstream.

Historically, Toyota’s innovative, consumer-friendly designs, such as fuel-efficient cars in the 1970s and hybrids in the 1990s, have revolutionized the auto industry. Now, Toyota’s solid-state battery development could do the same, potentially transforming EVs from niche to mainstream by offering greater efficiency, performance, and convenience.