Caltech researchers have discovered Hubbard excitons, which are excitons bound magnetically, offering new avenues for exciton-based technological applications.

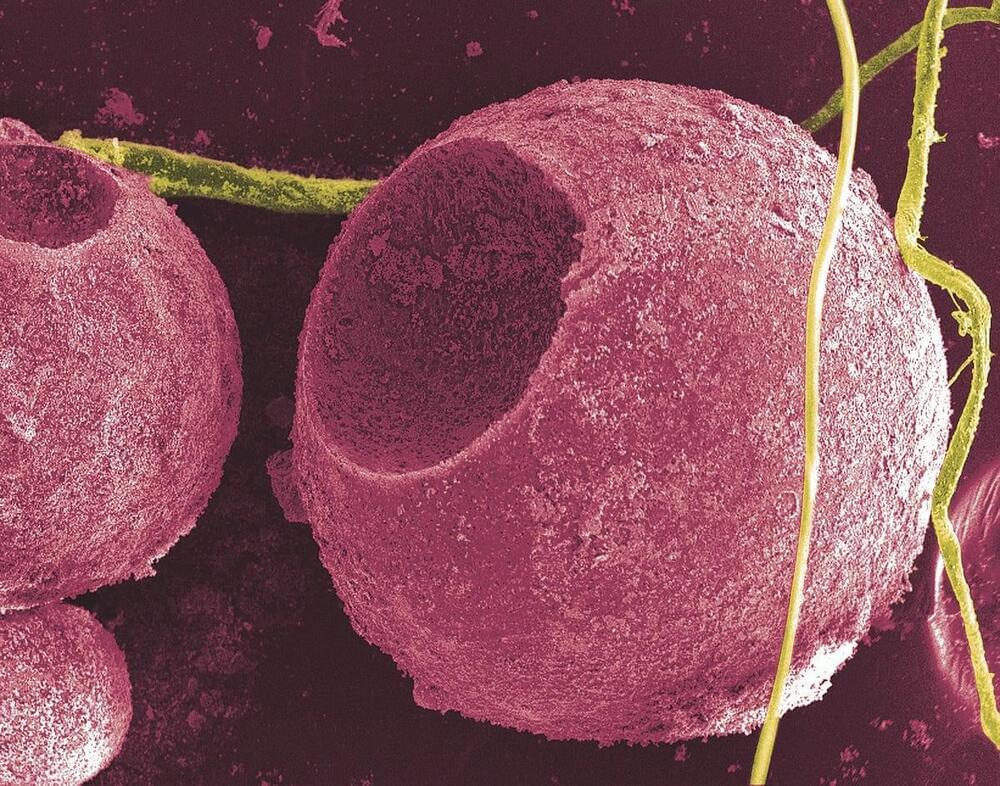

In art, the negative space in a painting can be just as important as the painting itself. Something similar is true in insulating materials, where the empty spaces left behind by missing electrons play a crucial role in determining the material’s properties. When a negatively charged electron is excited by light, it leaves behind a positive hole. Because the hole and the electron are oppositely charged, they are attracted to each other and form a bond. The resulting pair, which is short-lived, is known as an exciton [pronounced exit-tawn].

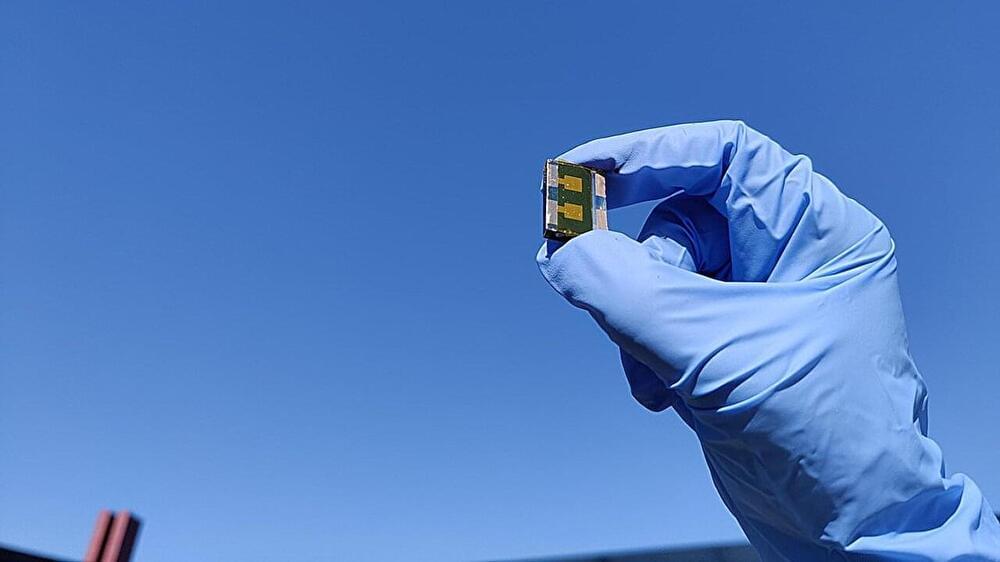

Excitons are integral to many technologies, such as solar panels, photodetectors, and sensors. They are also a key part of light-emitting diodes found in televisions and digital display screens. In most cases, the exciton pairs are bound by electrical, or electrostatic, forces, also known as Coulomb interactions.