The method, which works in conjunction with a deep-learning AI, identifies materials by their texture.

Game-playing artificial intelligence (AI) systems have advanced to a new frontier. Stratego, the classic board game that’s more complex than chess and Go, and craftier than poker, has now been mastered. Published in Science, we present DeepNash, an AI agent that learned the game from scratch to a human expert level by playing against itself.

DeepNash uses a novel approach, based on game theory and model-free deep reinforcement learning. Its play style converges to a Nash equilibrium, which means its play is very hard for an opponent to exploit. So hard, in fact, that DeepNash has reached an all-time top-three ranking among human experts on the world’s biggest online Stratego platform, Gravon.

Board games have historically been a measure of progress in the field of AI, allowing us to study how humans and machines develop and execute strategies in a controlled environment. Unlike chess and Go, Stratego is a game of imperfect information: players cannot directly observe the identities of their opponent’s pieces.

Machine learning has increased considerably in several areas due to its performance in recent years. Thanks to modern computers’ computing capacity and graphics cards, deep learning has made it possible to achieve results that sometimes exceed those experts give. However, its use in sensitive areas such as medicine or finance causes confidentiality issues. A formal privacy guarantee called differential privacy (DP) prohibits adversaries with access to machine learning models from obtaining data on specific training points. The most common training approach for differential privacy in image recognition is differential private stochastic gradient descent (DPSGD). However, the deployment of differential privacy is limited by the performance deterioration caused by current DPSGD systems.

The existing methods for differentially private deep learning still need to operate better since that, in the stochastic gradient descent process, these techniques allow all model updates regardless of whether the corresponding objective function values get better. In some model updates, adding noise to the gradients might worsen the objective function values, especially when convergence is imminent. The resulting models get worse as a result of these effects. The optimization target degrades, and the privacy budget is wasted. To address this problem, a research team from Shanghai University in China suggests a simulated annealing-based differentially private stochastic gradient descent (SA-DPSGD) approach that accepts a candidate update with a probability that depends on the quality of the update and the number of iterations.

Concretely, the model update is accepted if it gives a better objective function value. Otherwise, the update is rejected with a certain probability. To prevent settling into a local optimum, the authors suggest using probabilistic rejections rather than deterministic ones and limiting the number of continuous rejections. Therefore, the simulated annealing algorithm is used to select model updates with probability during the stochastic gradient descent process.

Researchers have created a deep learning method that can predict which patients might be eligible for life-saving medication that can prevent both diseases.

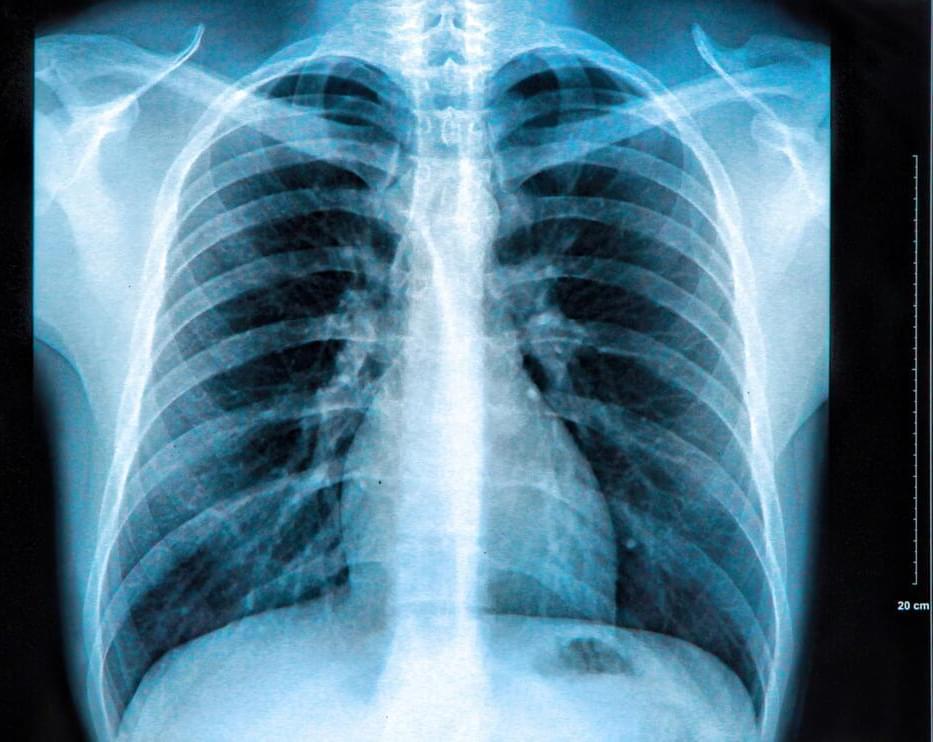

A new artificial intelligence model has been created that uses deep learning to predict the 10-year risk of death from a heart attack or stroke from a single X-ray. The results from the study were presented on Nov. 29 at the Radiological Society of North America (RSNA) annual meeting.

AI used to predict patterns of heart attacks and strokes

Deep learning uses artificial intelligence to ‘learn’ and view X-ray images to find patterns associated with various diseases, in this case, a stroke or heart attack.

Using the Versius surgical robot permitted a keyhole, or minimal access surgical approach, in an otherwise open surgery.

A robot at Gloucestershire Royal Hospital (GRH), United Kingdom, saved the life of a 61-year-old patient by removing a cancerous tumor from their throat, in what can be called a first in the country.

“To have been given a second chance to see my grandchildren, my children, and my wife has meant so much to me. The team at the GRH saved my life, and I’ll be forever grateful to them for doing so,” Nugent told Gloucestershire Live in an interview.

Versius/CMR Surgical.

Grandfather Martin Nugent is in high spirits after a surgical team comprising Gloucestershire Royal Hospital surgeons Simon Higgs and Steve Hornby employed Versius, a modern, cutting-edge robot from CMR Surgical, to operate earlier in July.

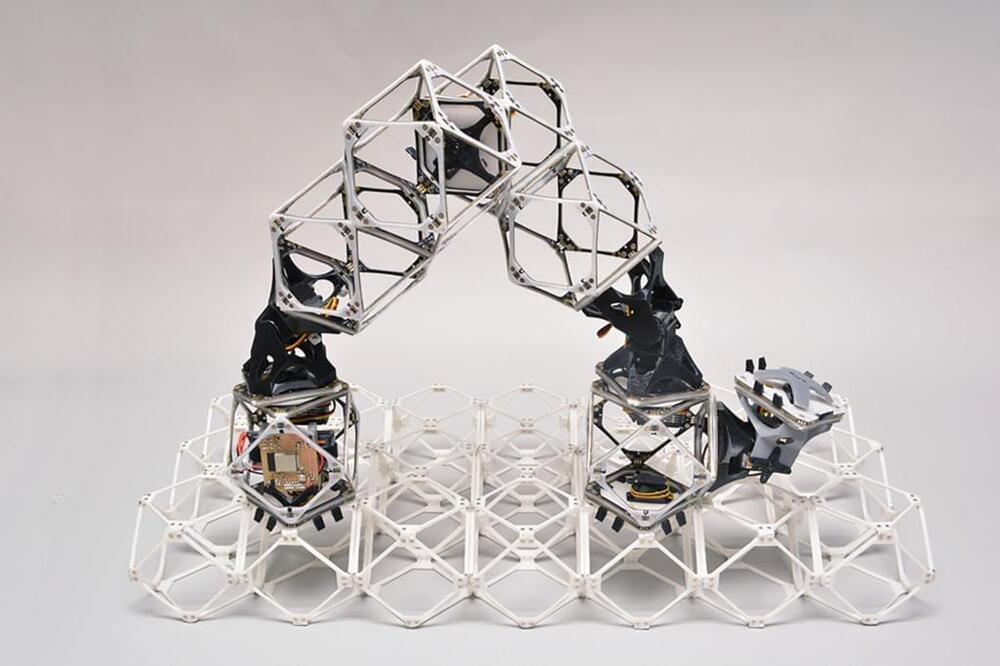

Massachusetts Institute of Technology (MIT) researchers are building swarms of tiny robots that have built-in intelligence, allowing them to build structures, vehicles, or even larger versions of themselves.

The subunit of the robot, which is being developed at MIT’s Center for Bits and Atoms, is called a voxel and is capable of carrying power and data.

“When we’re building these structures, you have to build in intelligence,” MIT Professor and CBA Director Neil Gershenfeld said in a statement. “What emerged was the idea of structural electronics — of making voxels that transmit power and data as well as force.”

New work from Gero, conducted in collaboration with researchers from Roswell Park Comprehensive Cancer Center and Genome Protection Inc. and published in Nature Communications, demonstrates the power of AI combined with analytical tools borrowed from the physics of complex systems to provide insights into the nature of aging, resilience and future medical interventions for age-related diseases including cancer.

Longevity. Technology: Modern AI systems exhibit superhuman-level performance in medical diagnostics applications, such as identifying cancer on MRI scans. This time, the researchers took one step further and used AI to figure out principles that describe how the biological process of aging unfolds in time.

The researchers trained an AI algorithm on a large dataset composed of multiple blood tests taken along the life course of tens of thousands of aging mice to predict the future health state of an animal from its current state. The artificial neural network precisely projected the health condition of an aging mouse with the help of a single variable, which was termed dynamic frailty indicator (dFI) that accurately characterises the damage that an animal accumulates throughout life [1].

Neura Pod is a series covering topics related to Neuralink, Inc. Topics such as brain-machine interfaces, brain injuries, and artificial intelligence will be explored. Host Ryan Tanaka synthesizes informationopinions, and conducts interviews to easily learn about Neuralink and its future.

Twitter: https://www.twitter.com/ryantanaka3/

Support: https://www.patreon.com/neurapod/

Please consider supporting by joining the channel above, or sharing my other company website with retirees: https://www.reterns.com/. Opinions are my own. Neura Pod receives no compensation from Neuralink and has no affiliation to the company.

#Neuralink #ElonMusk #Tesla