Scientists at Osaka University, in cooperation with Joanneum Research (Weiz, Austria), have developed wireless health monitoring patches that use embedded piezoelectric nanogenerators to power themselves with harvested biomechanical energy. This work may lead to new autonomous health sensors as well as battery-free wearable electronic devices.

As wearable technology and smart sensors become increasingly popular, the problem of providing power to all of these devices become more relevant. While the energy requirements of each component may be modest, the need for wires or even batteries become burdensome and inconvenient. That is why new energy harvesting methods are needed. Also, the ability for integrated health monitors to use ambient motion to both power and activate sensors will help accelerate their adoption in doctor’s offices.

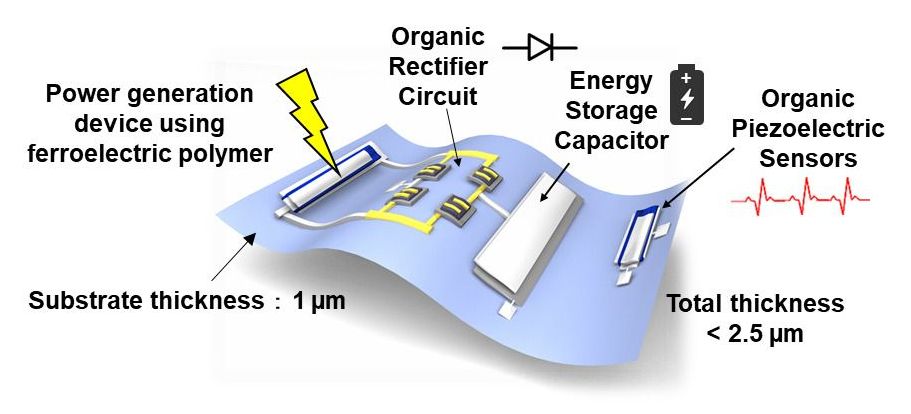

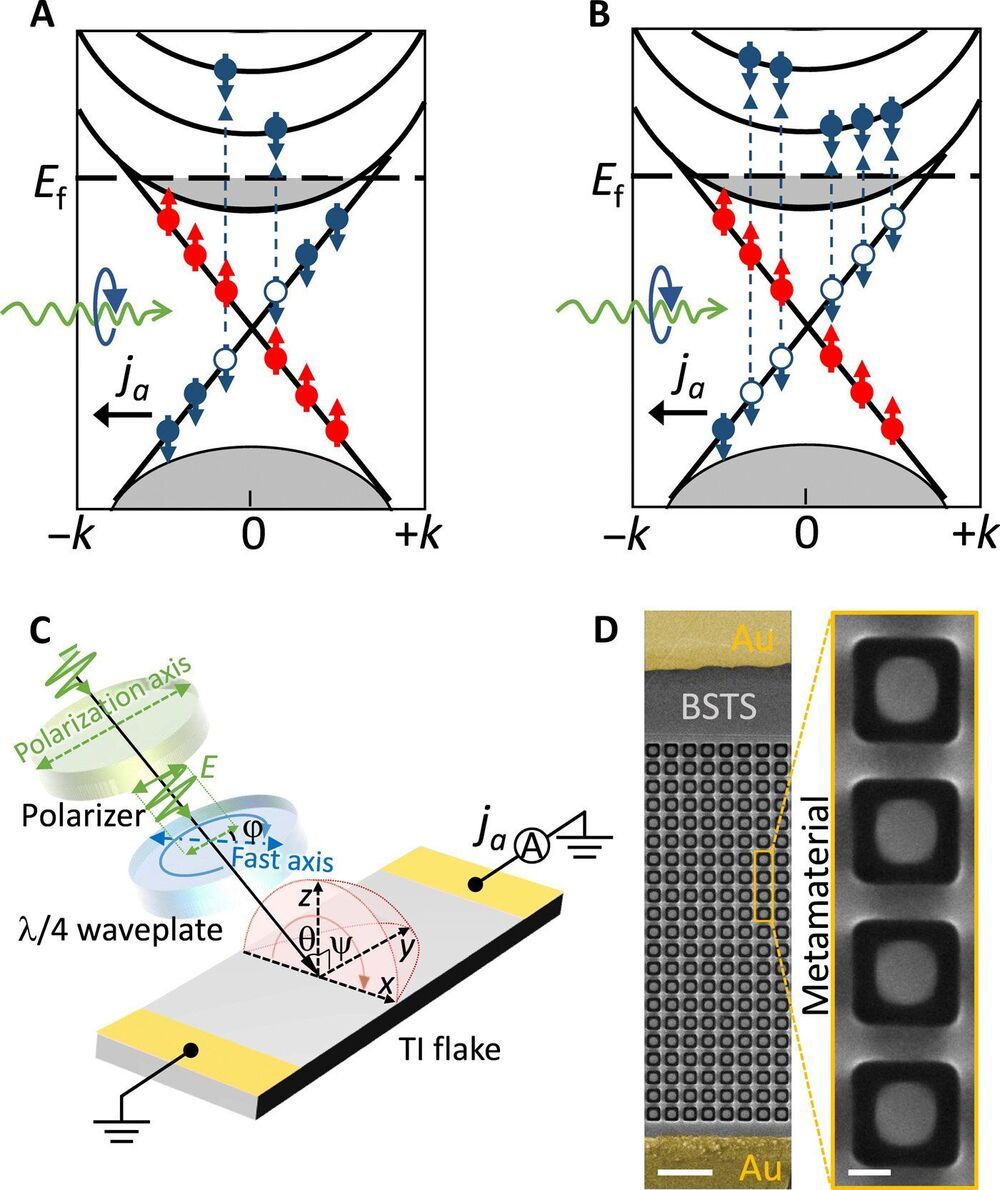

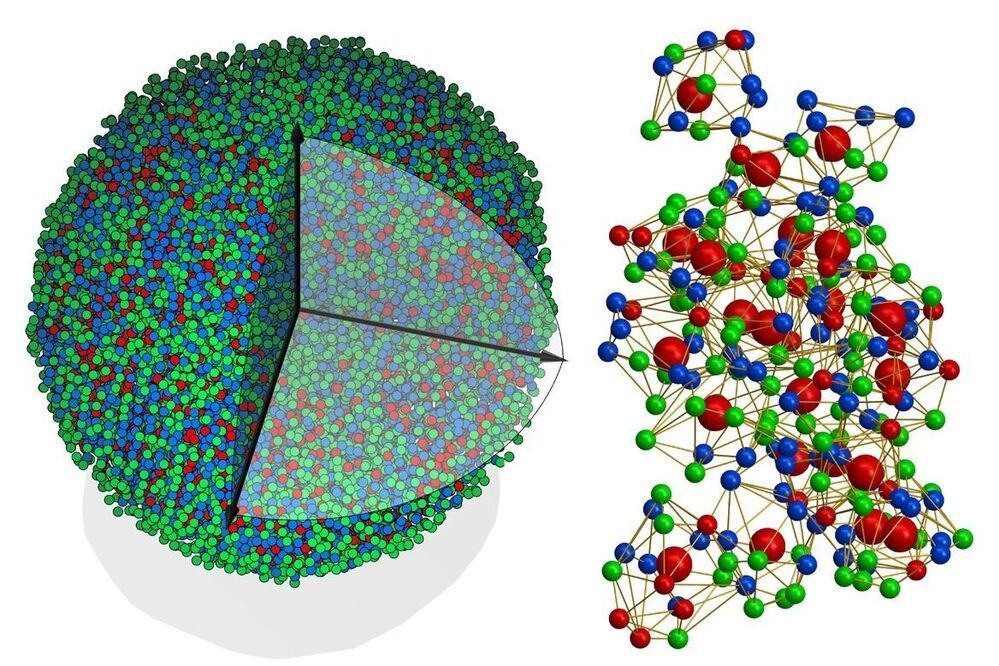

Now, an international team of researchers from Japan and Austria has invented new ultraflexible patches with a ferroelectric polymer that can not only sense a patient’s pulse and blood pressure, but also power themselves from normal movements. The key was starting with a substrate just one micron thick. Using a strong electric field, ferroelectric crystalline domains in a copolymer were aligned so that the sample had a large electric dipole moment. Based on the piezoelectric effect, which is very efficient in converting natural motion into small electric voltages, the device responds rapidly to strain or pressure changes. These voltages can be transduced either into signals for the medical sensors or to directly harvest the energy. “Our e-health patches may be employed as part of screening for lifestyle-related diseases such as heart disorders, signs of stress, and sleep apnea,” first-author Andreas Petritz says.