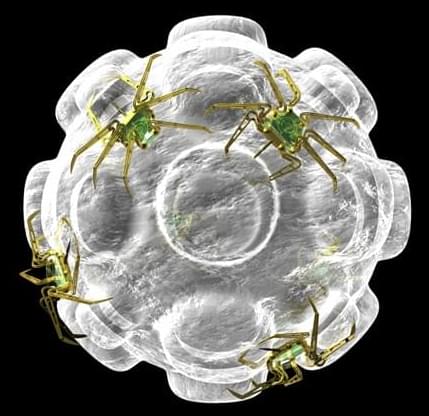

A Ludwig Cancer Research study has developed a novel nanotechnology that triggers potent therapeutic anti-tumor immune responses and demonstrated its efficacy in mouse models of multiple cancers. Led by Co-director Ralph Weichselbaum, investigator Wenbin Lin and postdoctoral researcher Kaiting Yang at the Ludwig Center at Chicago, the study describes the synthesis, mechanism of action and preclinical assessment of the nanoparticle, which is loaded with a drug that activates a protein central to the efficient induction of anti-cancer immunity. The study, which overcomes significant technical barriers to targeting that protein-;stimulator of interferon genes, or STING-;for cancer therapy, appears in the current issue of Nature Nanotechnology.

“The nanoparticles developed by the Lin lab release a drug that targets macrophages and can activate potent antitumor immune responses that extend the survival of mice bearing a variety of tumors,” said Chicago Center Co-director Weichselbaum. “When used in combination with radiotherapy and immunotherapy, they even help control ‘cold tumors’ that are otherwise almost completely impervious to immune attack.”

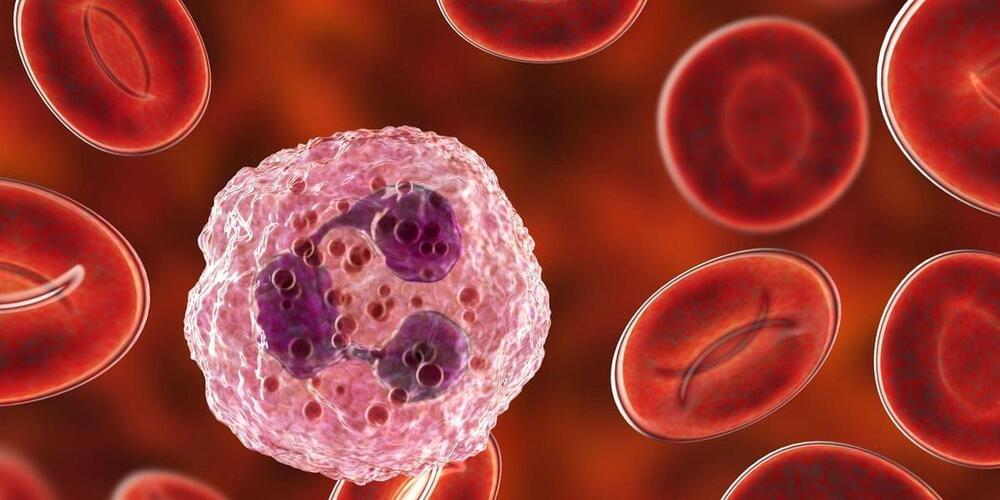

STING is part of cellular sensing system for DNA fragments, which are generated by infection or cancer treatments that damage DNA, like radiotherapy and some chemotherapies. Its activation promotes inflammation and drives immune cells like macrophages and dendritic cells to process and present cancer antigens to T cells, helping to stimulate and direct the immune assault on tumors. Though STING is a prized target for drug development, the drug-like molecules that can activate the molecular sensor-;known as cyclic dinucleotides (CDNs)-;have been plagued by issues of poor bioavailability, low stability and high toxicity in the absence of any means to target them specifically to tumors.