Stanford materials engineers have 3D printed tens of thousands of hard-to-manufacture nanoparticles long predicted to yield promising new materials that change form in an instant.

A study from the Instituto de Astrofísica de Canarias (IAC) which combines laboratory chemistry with astrophysics, has shown for the first time that grains of dust formed by carbon and hydrogen in a highly disordered state, known as HAC, can take part in the formation of fullerenes, carbon molecules which are of key importance for the development of life in the universe, and with potential applications in nanotechnology. The results are published in the journal Astronomy & Astrophysics.

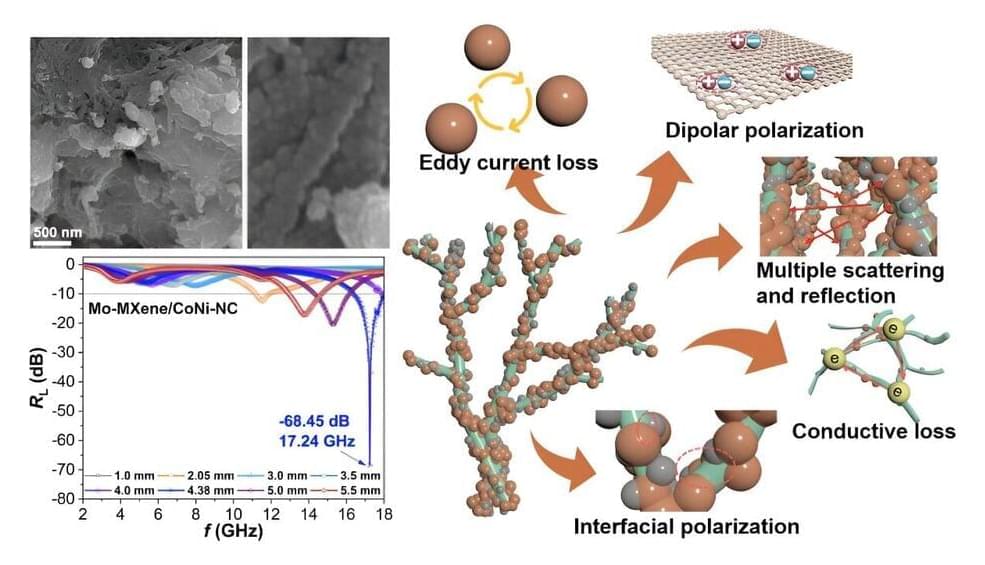

Two-dimensional transition metal carbides (MXene) possess attractive conductivity and abundant surface functional groups, providing immense potential in the field of electromagnetic wave (EMW) absorption. However, high conductivity and spontaneous aggregation of MXene suffer from limited EMW response. Inspired by dielectric–magnetic synergy effect, the strategy of decorating MXene with magnetic elements is expected to solve this challenge.

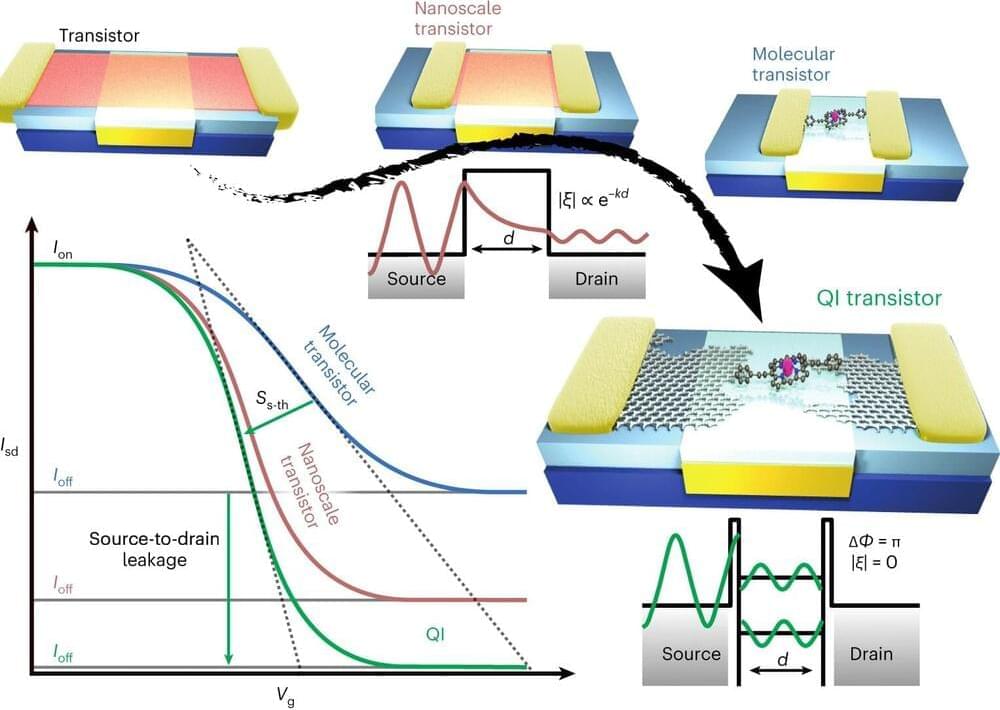

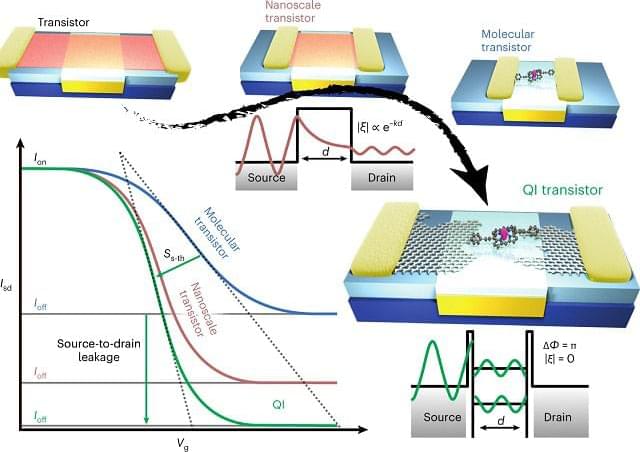

As transistors get smaller, they become increasingly inefficient and susceptible to errors, as electrons can leak through the device even when it is supposed to be switched off, by a process known as quantum tunneling. Researchers are exploring new types of switching mechanisms that can be used with different materials to remove this effect.

In the nanoscale structures that Professor Jan Mol, Dr. James Thomas, and their group study at Queen Mary’s School of Physical and Chemical Sciences, quantum mechanical effects dominate, and electrons behave as waves rather than particles. Taking advantage of these quantum effects, the researchers built a new transistor.

The transistor’s conductive channel is a single zinc porphyrin, a molecule that can conduct electricity. The porphyrin is sandwiched between two graphene electrodes, and when a voltage is applied to the electrodes, electron flow through the molecule can be controlled using quantum interference.

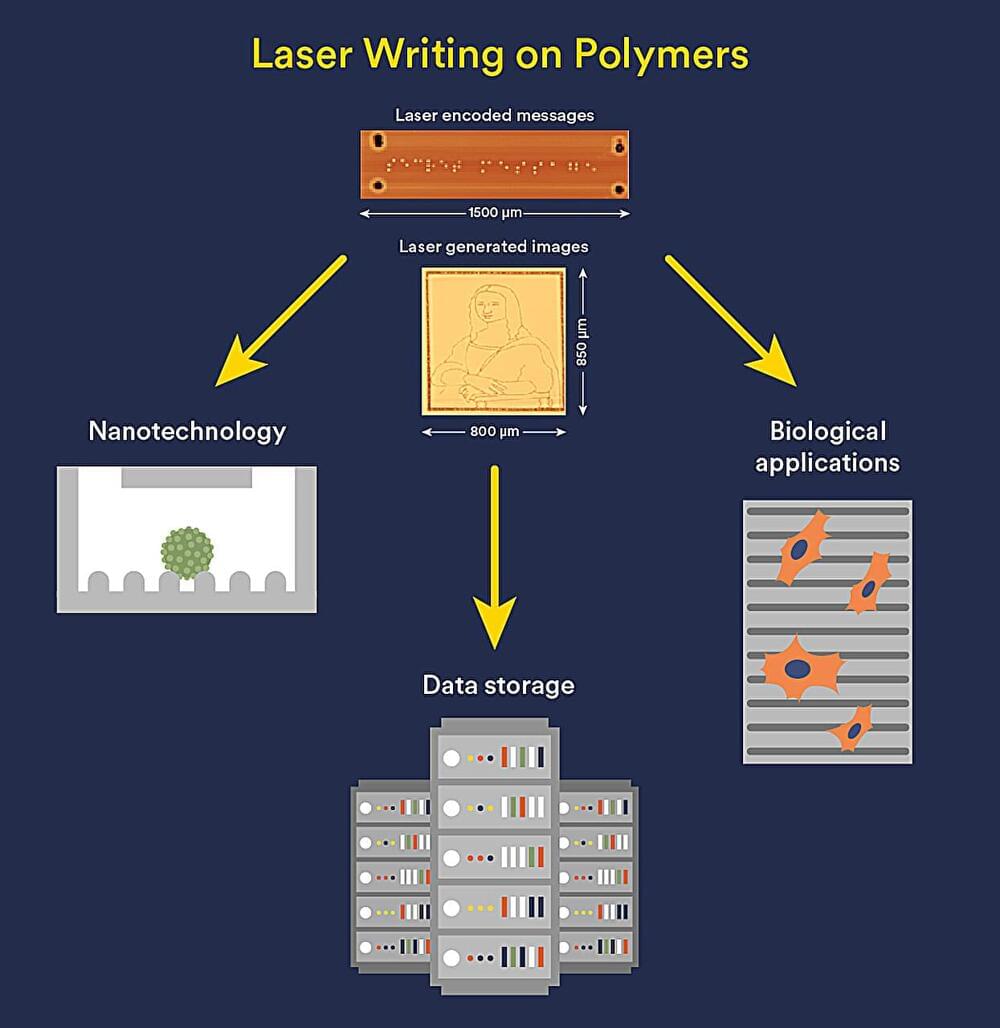

Now Flinders University researchers have discovered a light-responsive, inexpensive sulfur-derived polymer receptive to low power, visible light lasers—which promises a more affordable and safer production method in nanotech, chemical science and patterning surfaces in biological applications.

Details of the novel system have just been published in Angewandte Chemie International Edition, featuring a laser-etched version of the famous “Mona Lisa” painting and micro-Braille printing even smaller than a pin head.

“This could be a way to reduce the need for expensive, specialized equipment, including high-power lasers with hazardous radiation risk, while also using more sustainable materials. For instance, the key polymer is made from low-cost elemental sulfur, an industrial byproduct, and either cyclopentadiene or dicyclopentadiene,” says Matthew Flinders Professor of Chemistry Justin Chalker, from the Flinders University.

During cell division, a ring forms around the cell equator, which contracts to divide the cell into two daughter cells. Together with researchers from Heidelberg, Dresden, Tübingen and Harvard, Professor Jan Kierfeld and Lukas Weise from the Department of Physics at TU Dortmund University have succeeded for the first time in synthesizing such a contractile ring with the help of DNA nanotechnology and to uncover its contraction mechanism.

The results have been published in the journal Nature Communications (“Triggered contraction of self-assembled micron-scale DNA nanotube rings”).

In synthetic biology, researchers try to recreate crucial mechanisms of life in vitro, such as cell division. The aim is to be able to synthesize minimal cells. The research team led by Professor Kerstin Göpfrich from Heidelberg University has now synthetically reproduced contractile rings for cell division using polymer rings composed of DNA nanotubes.

An international team of researchers from Queen Mary University of London, the University of Oxford, Lancaster University, and the University of Waterloo have developed a new single-molecule transistor that uses quantum interference to control the flow of electrons. The transistor, which is described in a paper published in the Nature Nanotechnology (“Quantum interference enhances the performance of single-molecule transistors”), opens new possibilities for using quantum effects in electronic devices.

Transistor are the basic building blocks of modern electronics. They are used to amplify and switch electrical signals, and they are essential for everything from smartphones to spaceships. However, the traditional method of making transistors, which involves etching silicon into tiny channels, is reaching its limits.

As transistors get smaller, they become increasingly inefficient and susceptible to errors, as electrons can leak through the device even when it is supposed to be switched off, by a process known as quantum tunnelling. Researchers are exploring new types of switching mechanisms that can be used with different materials to remove this effect.

Carbon nanotubes are cylindrical molecules that consist of rolled-up sheets of single-layer carbon atoms (graphene); they possess unique properties like high aspect ratio, mechanical strength, electrical and thermal conductivity, chemical stability, and a tip-surface area near the theoretical limit. They are one of the strongest materials known to man.

Researchers from Tohoku University have created a theoretical framework for an advanced spin wave reservoir computing (RC) system that leverages spintronics. This innovation advances the field toward realizing energy-efficient, nanoscale computing with unparalleled computational power.

Details of their findings were published in npj Spintronics on March 1, 2024.

“Cannabis vapes are newly regulated products in Canada, so we don’t yet have much scientific data about them,” said Dr. Andrew Waye. “This is an opportunity for us to look at some of the questions concerning the risks and unknowns of cannabis vapes.”

Do vapes pose health risks on par with the very tobacco and cannabis products it’s using to safeguard against? This is what a recent study presented at the ACS (American Chemical Society) Spring 2024 meeting hopes to address as a team of researchers investigated the potential health risks that vaping devices could pose, specifically pertaining to the vaping liquids that possess toxic metal nanoparticles, with both regulated and unregulated vaping devices. This study holds the potential to help researchers, medical professionals, and the public better understand the long-term health risks by vaping, which until now have been deemed a “safer” alternative to smoking cigarettes or cannabis.