Lawrence Livermore National Laboratory (LLNL) researchers have developed a novel 3D printing technique that uses light to build complex structures, then cleanly dissolves the support material, expanding possibilities in multi-material additive manufacturing (AM).

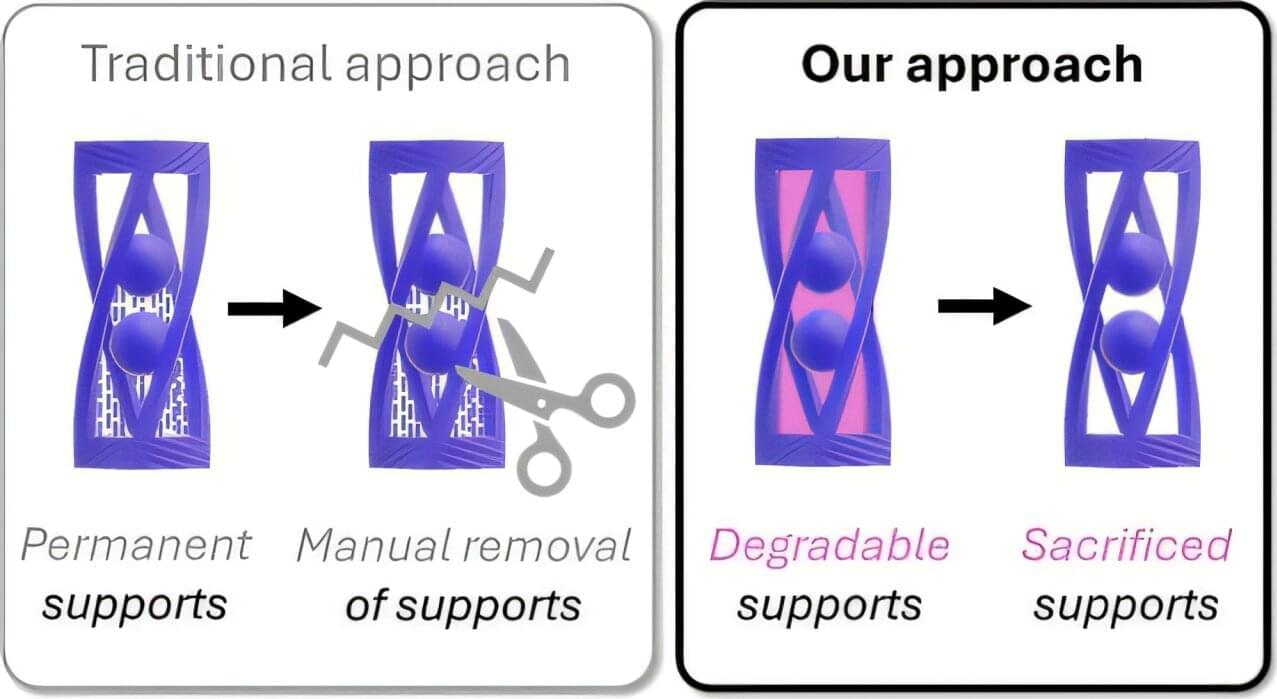

In 3D printing, traditional supports often add time, waste and risk to the process, especially when printing intricate parts. But in a new study published in ACS Central Science, an LLNL team—in collaboration with University of California, Santa Barbara (UCSB) researchers—outlines a “one-pot” printing approach that uses two light wavelengths to simultaneously create permanent structures and temporary supports from a single resin formulation.

The method addresses a longstanding challenge in AM: how to fabricate suspended or overhanging features without cumbersome scaffolding requiring manual removal, which is a key hurdle to the widespread adoption of digital light processing (DLP) 3D printing technologies.