Diamond is one of the most prized materials in advanced technologies due to its unmatched hardness, ability to conduct heat and capacity to host quantum-friendly defects. The same qualities that make diamond useful also make it difficult to process.

Engineers and researchers who work with diamond for quantum sensors, power electronics or thermal management technologies need it in ultrathin, ultrasmooth layers. But traditional techniques, like laser cutting and polishing, often damage the material or create surface defects.

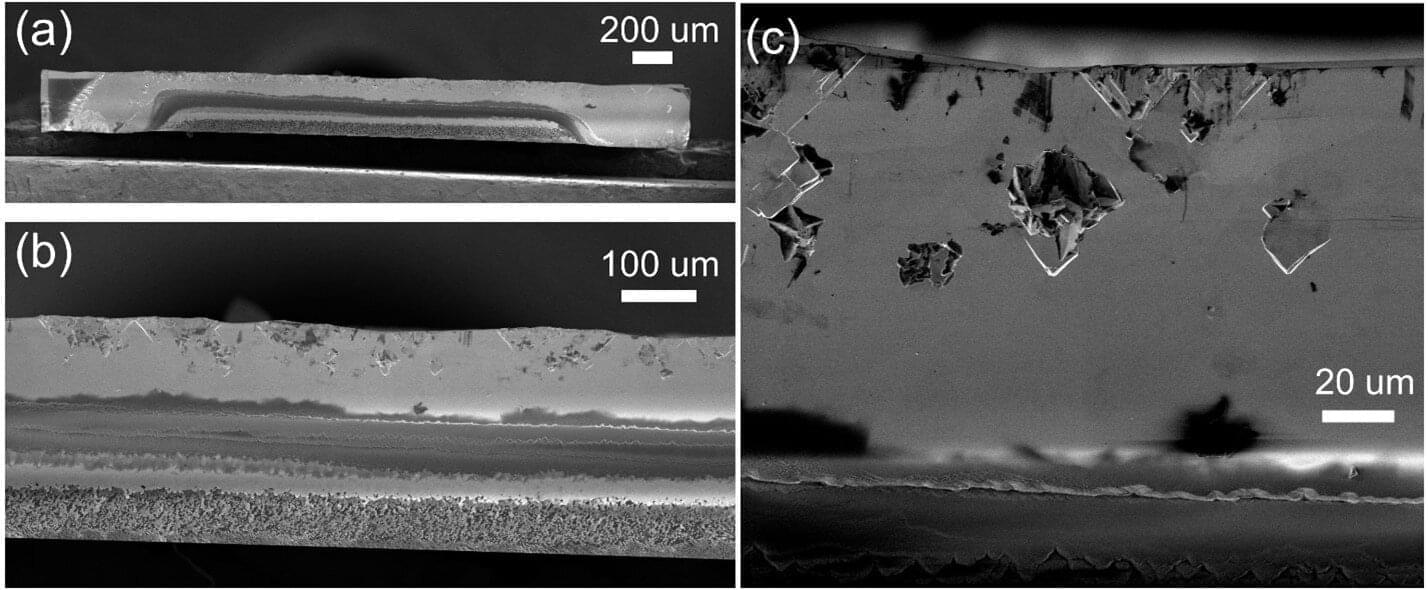

Ion implantation and lift-off is a way to separate a thin layer of diamond from a larger crystal by bombarding a diamond substrate with high-energy carbon ions, which penetrate to a specific depth below the surface. The process creates a buried layer in the diamond substrate where the crystalline lattice has been disrupted. That damaged layer effectively acts like a seam: Through high-temperature annealing, it turns into smooth graphite, allowing for the diamond layer above it to be lifted off in one uniform, ultrathin wafer.