Adopting liquid cooling technology could significantly reduce electricity costs across the data center.

Many Porsche “purists” reflect forlornly upon the 1997, 5th generation, 996 version of the iconic 911 sports car. It was the first year of the water-cooled engine versions of the 911, which had previously been based on air-cooled engines since their entry into the market in 1964. The 911 was also the successor to the popular air-cooled 356. For over three decades, Porsche’s flagship 911 was built around an air-cooled engine. The two main reasons often provided for the shift away from air-cooled to water-cooled engines were 1) environmental (emission standards) and 2) performance (in part cylinder head cooling). The writing was on the wall: If Porsche was going to remain competitive in the sports car market and racing world, the move to water-cooled engines was unavoidable.

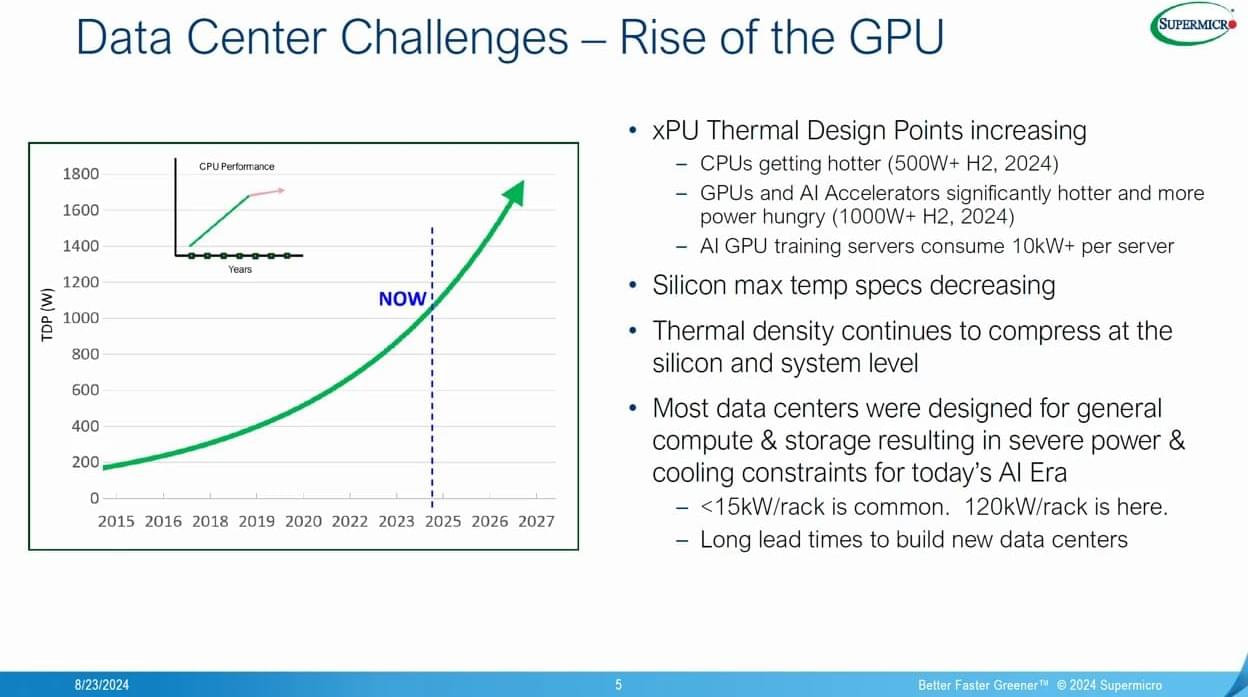

Fast forward to current data centers trying to meet the demands for AI computing. For similar reasons, we’re seeing a shift towards liquid cooling. Machines relying on something other than air for cooling date back at least to the Cray-1 supercomputer which used a freon-based system and the Cray-2 which used Fluorinert, a non-conductive liquid in which boards were immersed. The Cray-1 was rated at about 115kW and the Cray-2 at 195kW, both a far cry from the 10’s of MWs used by today’s most powerful supercomputers. Another distinguishing feature here is that these are “supercomputers” and not just data center servers. Data centers have largely run on air-cooled processors, but with the incredible demand for computing created by the explosive increase in AI applications, data centers are being called on to provide supercomputing-like capabilities.