About 100 million metric tons of high-density polyethylene (HDPE), one of the world’s most commonly used plastics, are produced annually, using more than 15 times the energy needed to power New York City for a year and adding enormous amounts of plastic waste to landfills and oceans.

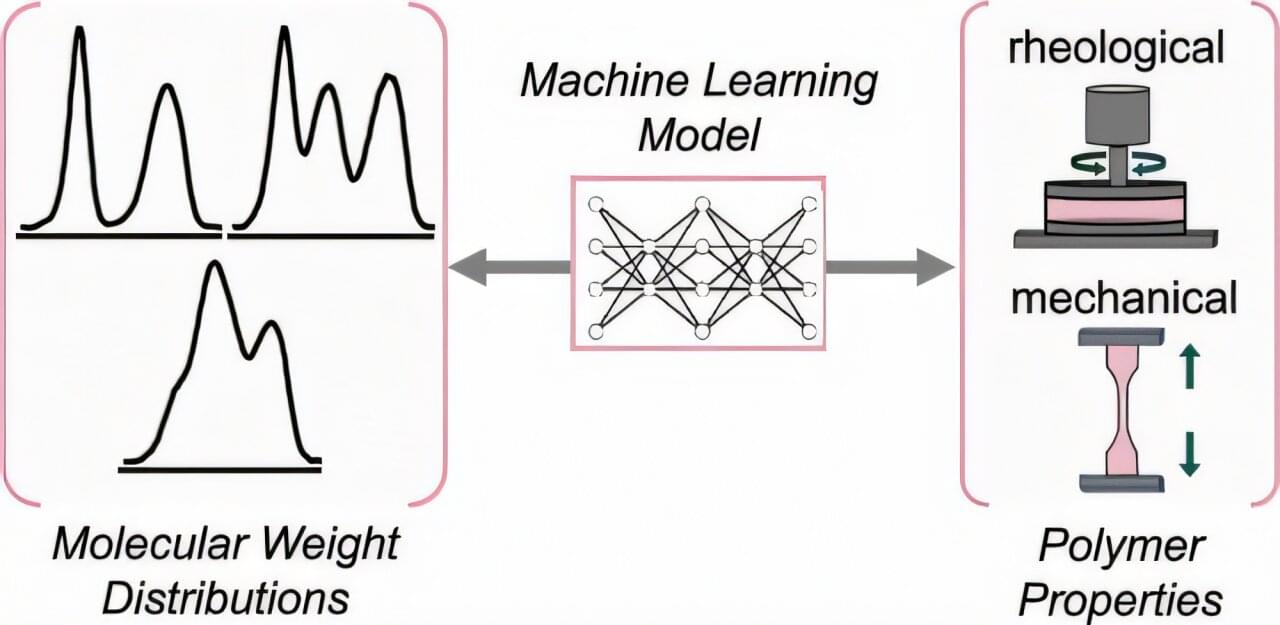

Cornell chemistry researchers have found ways to reduce the environmental impact of this ubiquitous polymer —found in milk jugs, shampoo bottles, playground equipment and many other things—by developing a machine-learning model that enables manufacturers to customize and improve HDPE materials, decreasing the amount of material needed for various applications. It can also be used to boost the quality of recycled HDPE to rival new, making recycling a more practical process.

“Implementation of this approach will facilitate the design of next-generation commodity materials and enable more efficient polymer recycling, lowering the overall impact of HDPE on the environment,” said Robert DiStasio Jr., associate professor of chemistry and chemical biology in the College of Arts and Sciences (A&S).