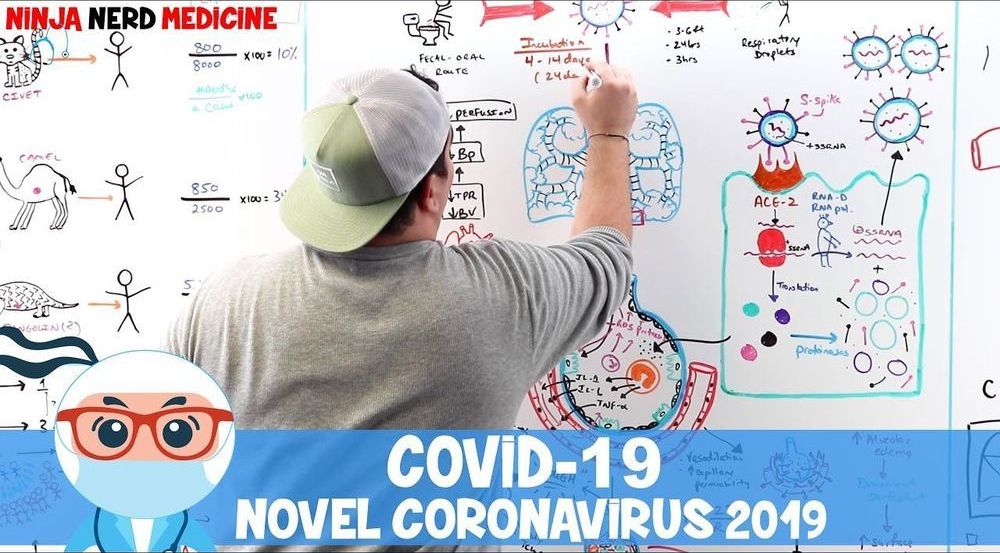

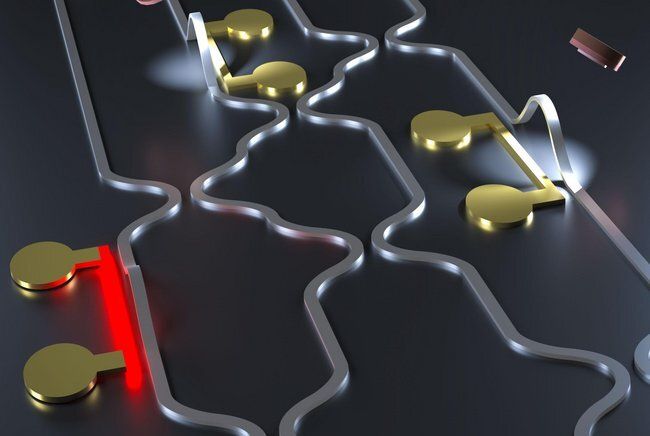

Modern society relies on technologies with electronic integrated circuits (IC) at their heart, but these may prove to be less suitable in future applications such as quantum computing and environmental sensing. Photonic integrated circuits (PICs), the light-based equivalent of electronic ICs, are an emerging technology field that can offer lower energy consumption, faster operation, and enhanced performance. However, current PIC fabrication methods lead to large variability between fabricated devices, resulting in limited yield, long delays between the conceptual idea and the working device, and lack of configurability. Researchers at Eindhoven University of Technology have devised a new process for the fabrication of PICs that addresses these critical issues, by creating novel reconfigurable PICs in the same way that the emergence of programmable logic devices transformed IC production in the 1980s.

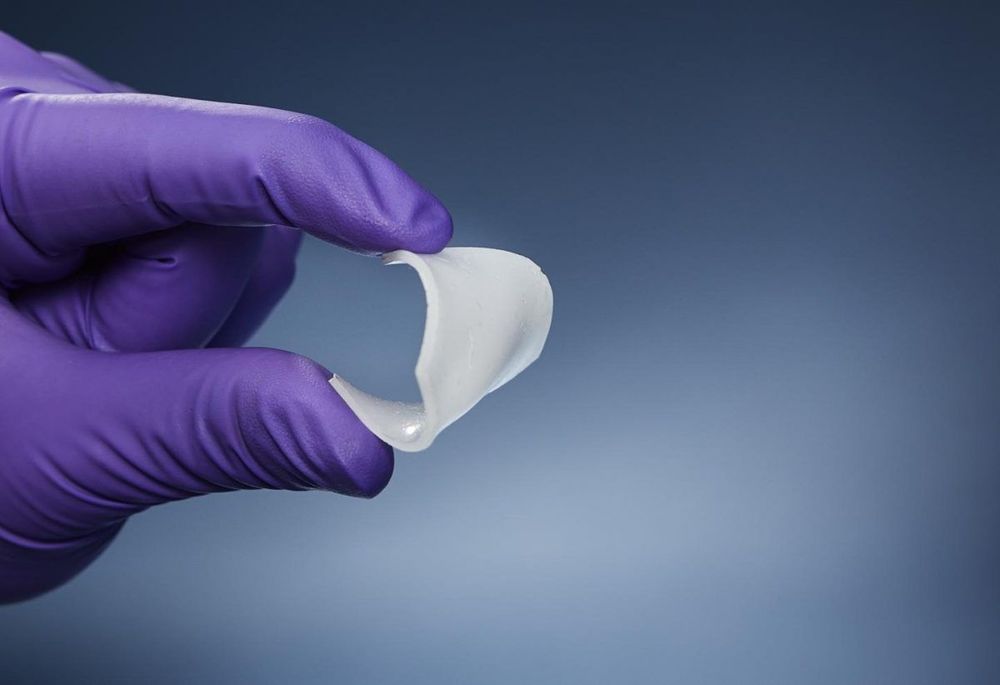

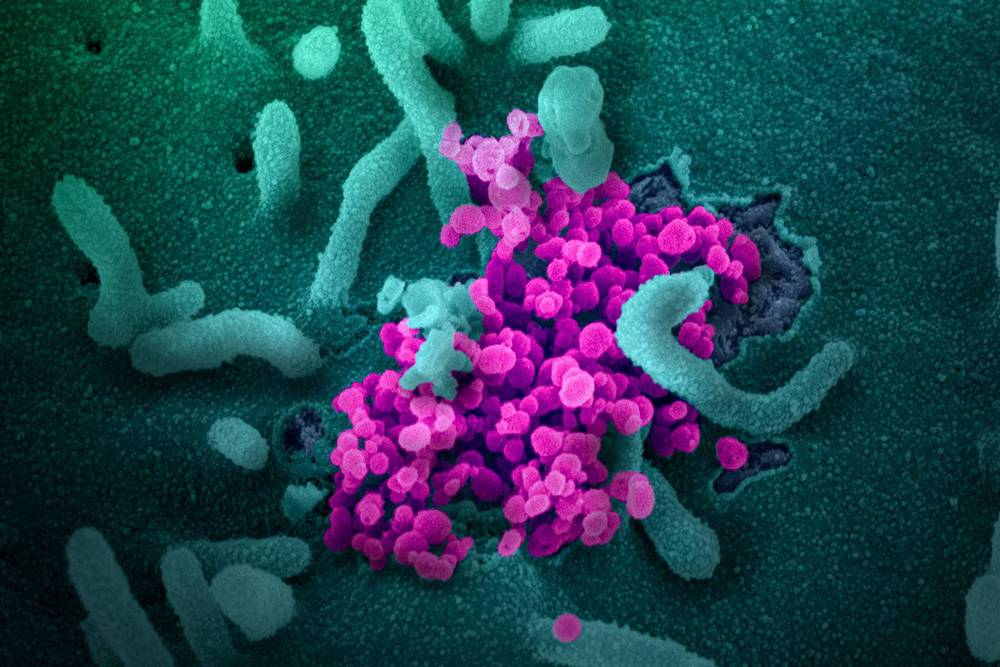

Photonic integrated circuits (PICs) – the light-based equivalent of electronic ICs—carry signals via visible and infrared light. Optical materials with adjustable refractive index are essential for reconfigurable PICs as they allow for more accurate manipulation of light passing through the materials, leading to better PIC performance.

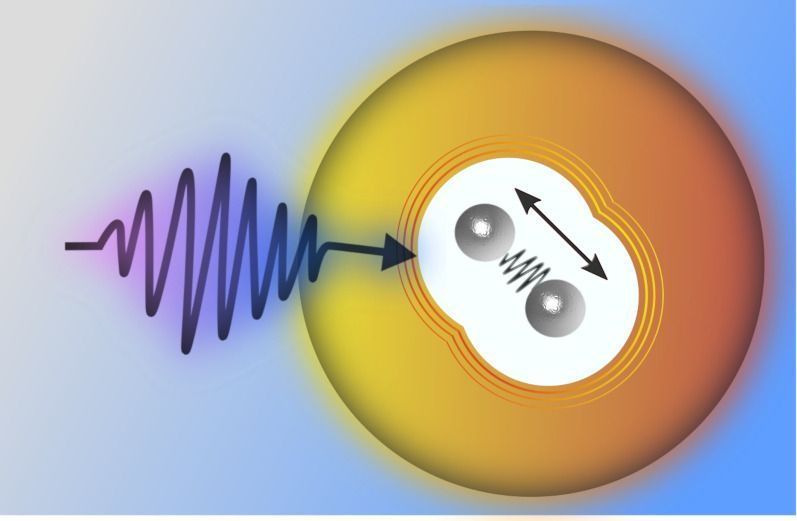

Current programmable PIC concepts suffer from issues such as volatility and/or high optical signal losses—both of which negatively affect a material’s ability to keep its programmed state. Using hydrogenated amorphous silicon (a-Si: H), a material used in thin-film silicon solar cells, and the associated Staebler-Wronski effect (SWE), which describes how the optical properties of a-Si: H can be changed via light exposure or heating, researchers at Eindhoven University of Technology have designed a new PIC fabrication process that addresses the shortfalls of current techniques and could lead to the emergence of universal programmable PICs.