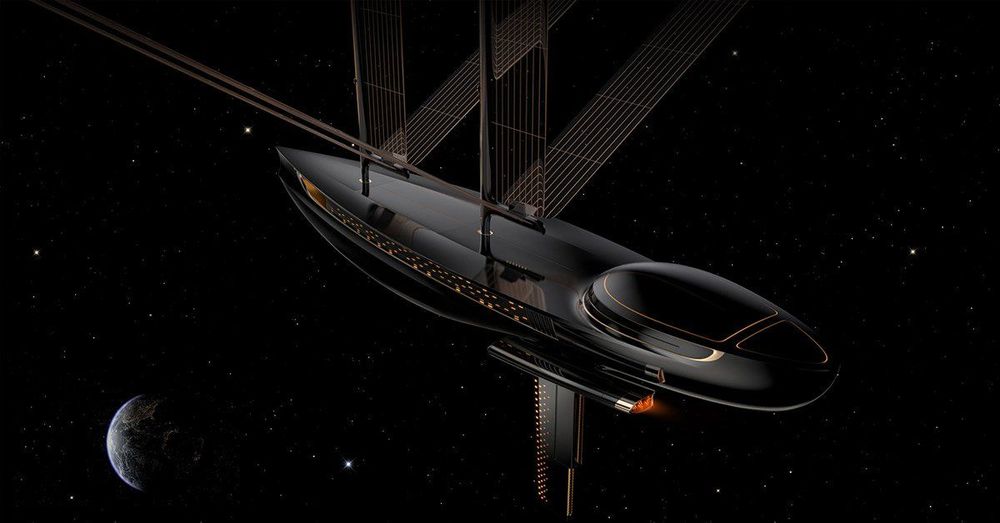

The ultimate way of building up space structures would be to use material sourced there, rather than launched from Earth. Once processed into finished composite material, the resin holds the carbon fibres together as a solid rather than a fabric. The beams can be used to construct more complex structures, antennae, or space station trusses. Image credit: All About Space/Adrian Mann.

The International Space Station is the largest structure in space so far. It has been painstakingly assembled from 32 launches over 19 years, and still only supports six crew in a little-under-a-thousand cubic metres of pressurised space. It’s a long way from the giant rotating space stations some expected by 2001. The problem is that the rigid aluminium modules all have to be launched individually, and assembled in space. Bigelow Aerospace will significantly improve on this with their inflatable modules that can be launched as a compressed bundle; but a British company has developed a system that could transform space flight, by building structures directly in space.

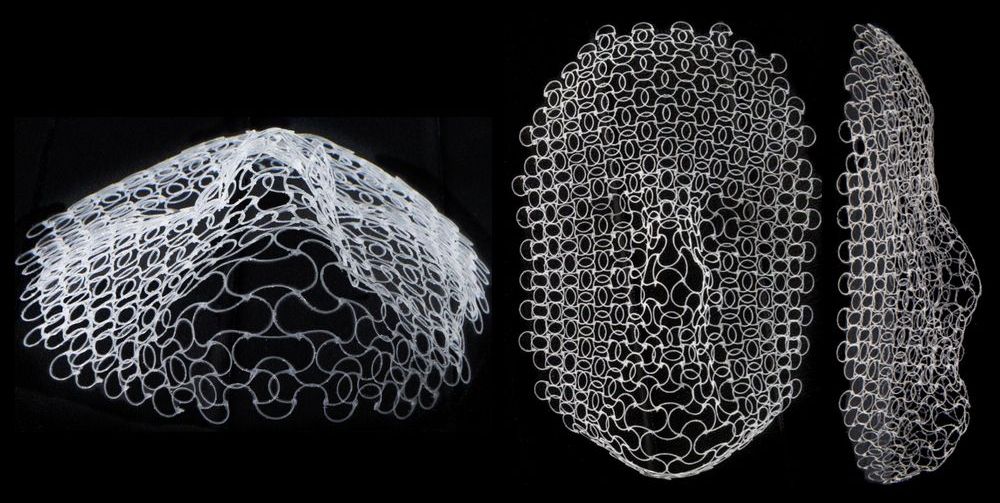

Magna Parva from Leicester are a space engineering consultancy, founded in 2005 by Andy Bowyer and Miles Ashcroft. Their team have worked on a range of space hardware, from methods to keep Martian solar panels clear of dust, to ultrasonic propellant sensors, to spacecraft windows. But their latest project is capable of 3D printing complete structures in space, using a process called pultrusion. Raw carbon fibres and epoxy resin are combined in a robotic tool to create carbon composite beams of unlimited length – like a spider creating a web much larger than itself. Building structures in space has a range of compounding virtues, it is more compact than even inflatables, as only bulk fibre and resin need to be launched. Any assembled hardware that has to go through a rocket launch has to be made much stronger than needed in space to survive the launch, printed structures can be designed solely for their in space application, using less material still.