Great work by my friends at ORNL.

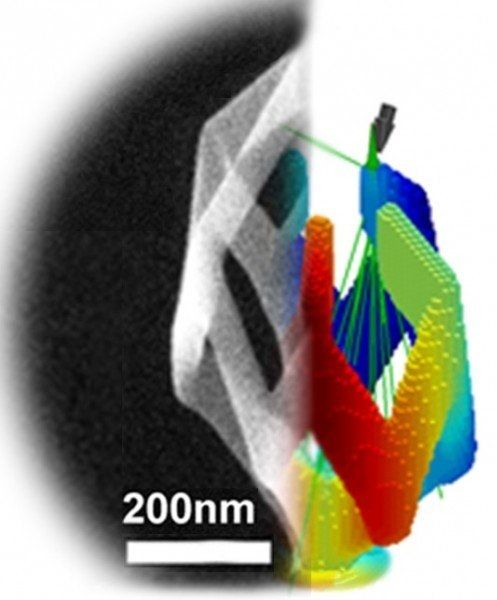

In a review paper published in ACS Nano, Olga Ovchinnikova and colleagues provide an overview of existing paths to 3D materials, but the ultimate goal is to create and customize material at the atomic scale. Material would be assembled atom by atom, much like children can use Legos to build a car or castle brick by brick. This concept, known as directed matter, could lead to virtually perfect materials and products because many limitations of conventional manufacturing techniques would be eliminated.

“Being able to assemble matter atom by atom in 3D will enable us to design materials that are stronger and lighter, more robust in extreme environments and provide economical solutions for energy, chemistry and informatics,” Ovchinnikova said.

Fundamentally, directed matter eliminates the need to remove unwanted material by lithography, etching or other traditional methods. These processes have served society well, researchers noted, but the next generation of materials and products require a new approach.

Comments are closed.