Researchers at MIT have developed a method of altering 3D printed objects once printed. The technique involves using light in order to adapt the chemical structure of a 3D printed material. This allows the creation of more complex objects which could be molded together, softened, or even enlarged.

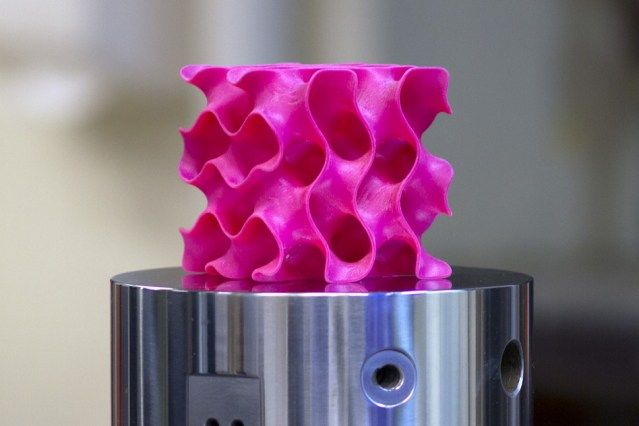

The university is a hub of 3D printing research. Recently announcement include their Computer Science and Artificial Intelligence Lab creating the ‘photoshop for 3D printing’. The ‘Foundry’ software was developed in order to make use of 3D printing’s advanced capabilities over conventional manufacturing techniques. Also addressing 3D printing technology, MIT researchers looked at using 3D printing to investigate how graphene might create the strongest material ever.

The newly published paper is called ‘Living Additive Manufacturing: Transformation of Parent Gels into Diversely Functionalized Daughter Gels Made Possible by Visible Light Photoredox Catalysis’ and available in the ACS Central Science Journal.

Thank you for this info. This would be great if 3D printed part could be expanded and softened after production. although we paint and do some other modifications to out 3d prints but if we can make it elastic that would be great.